Bonga is the first deep-water project for the Shell Nigeria Exploration and Production Company (SNEPCO) and for Nigeria.

The discovery well is located in oil prospecting license (OPL) 212, which was awarded during Nigeria’s first round of deep-water frontier acreage awards in 1993.

SNEPCO operates the field on behalf of the Nigerian National Petroleum Corporation (NNPC) and its partners under a production sharing contract. The partners in the field include Shell (55%), Esso (20%), Total (12.5%) and Agip (12.5%).

Crude oil production from the field started in November 2005 and the first shipment from the field was made in February 2006.

The field underwent its fourth turnaround maintenance (TAM) in 2017 and delivered 819 million barrels of oil by the end of 2018.

Bonga exploration

Bonga lies 120km south-west of the Niger Delta, in a water depth of over 1,000m.

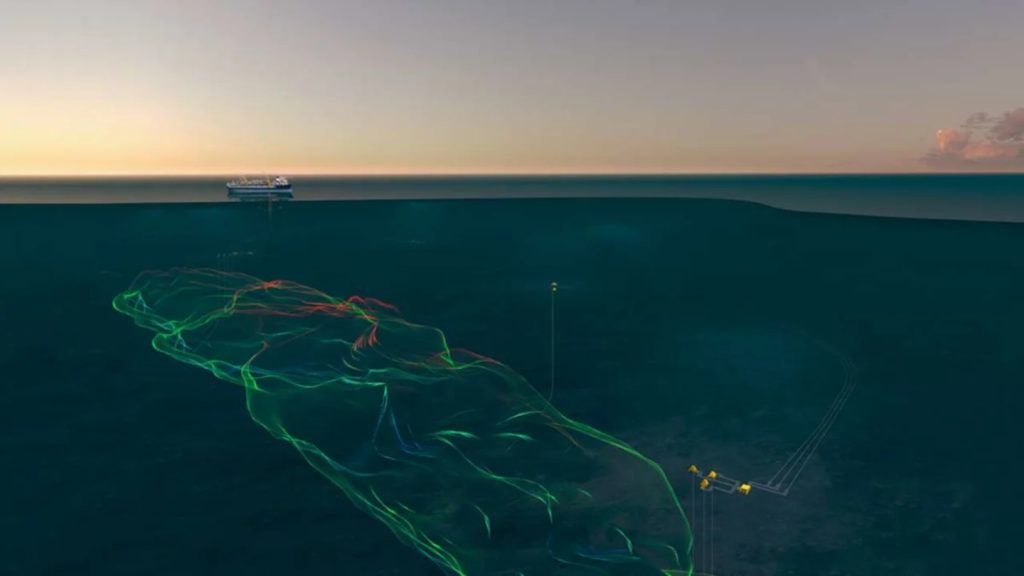

The real extent of the Bonga field is approximately 60km². After acquiring and processing 3D seismic data in 1993-94, the first Bonga discovery well was drilled between September 1995 and January 1996.

Shell drilled an exploration well on Bonga Southwest located 10km south-west of the Bonga field in May 2001. Bonga Southwest was drilled in a water depth of 1,245m.

The well reached its final depth of 4,160m and was subsequently logged and suspended. It encountered a substantial amount of net oil sand.

An initial evaluation of the well indicated that the recoverable reserves discovered with Bonga Southwest were large enough to form the basis for new deep-water development in OML118.

FPSO of Bonga field

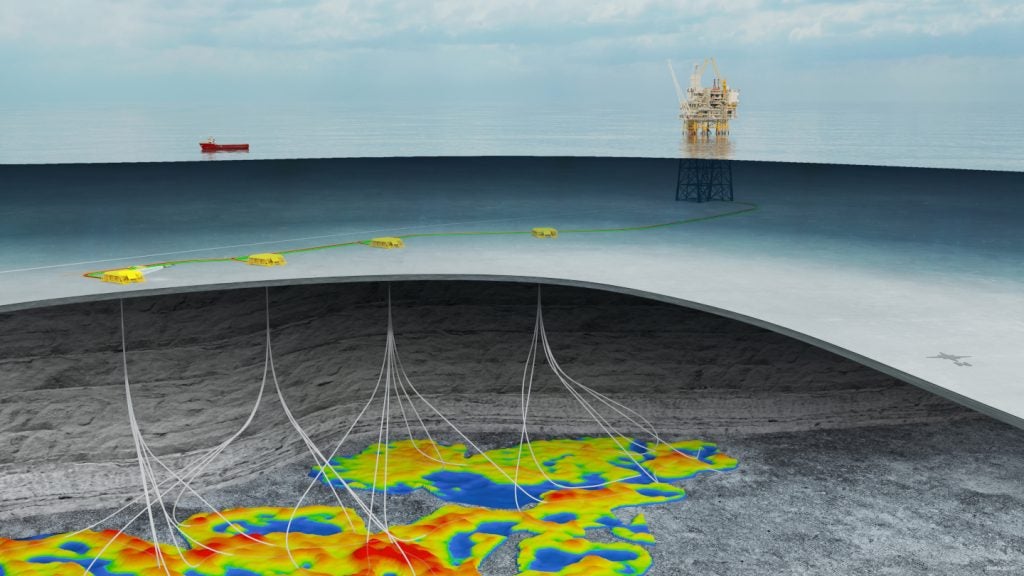

Shell decided on an FPSO development solution. The field has around 16 subsea oil-producing and water injection wells tied to the FPSO.

AMEC secured a £300m ($463m) offshore contract for the engineering design, fabrication, integration and commissioning of the 17,000t topside production facilities in 2001.

These were necessary to produce approximately 200,000 barrels of oil and 150 million standard cubic feet of natural gas a day.

The newly built hull arrived in the UK during the third quarter of 2002, following its construction in the Far East under a separate contract. The topsides were installed onto the hull to create the 300,000t FPSO.

The vessel achieved production of more than 800 million barrels of crude oil in 2018. It is amongst the largest FPSOs in the world.

Gas and oil export

Gas from the Bonga is connected to the Nigeria Liquefied Natural Gas (NLNG) plant at Bonny, where a third processing train was constructed.

LNG is exported to Atlantic and European markets via tankers. The oil is stored on-board the production facilities prior to direct offloading.

It can produce 200,000 barrels of oil per day and 150 million standard cubic feet of gas per day. The cost of the full field development was $3.6bn.

Contractors involved in the deep-water project

ABB won the $180m order for the engineering, procurement and construction (EPC) of all of the subsea equipment. This also included production-control umbilicals and gas-lift risers.

ABB supplied 29 conventional subsea trees and associated hardware under the deal in order to facilitate oil production from, and water injection into, the reservoir.

The deliveries of equipment continued until mid-2009.

The work included project management, the engineering and supply of manifolds, trees, wellheads, controls, connection systems, intervention equipment, integration testing and installation support.

Stolt Offshore signed an approximately $200m turnkey subsea construction contract to support the project.

The deal covered the design, engineering, procurement, installation and commissioning of the gas-export pipeline, production flowlines, water-injection lines and steel catenary risers.

Stolt Offshore began the design engineering and procurement work immediately.

The risers were fabricated in the second half of 2002 at the Stolt Offshore Nigerdock pipe reeling facility in Nigeria.

Installation works included rigid steel flowlines, together with steel catenary oil and gas-production risers.

Seaway Polaris installed 36km of 10in-diameter production flowlines and all the project’s steel catenary risers using the J Lay method.

Samsung Heavy Industries was awarded a contract to build the FPSO.

Additionally, Seaway Polaris handled the installation of the 92km-long, 16in-diameter gas-export pipeline that connected the Bonga FPSO to the Shell EA riser platform.

Seaway Kestrel installed 25km of 12in-diameter water-injection flowlines. Surveying and tie-in work was undertaken by Seaway Legend.

ClampOn delivered a topside system of sand sensors in February 2003.

An extension to the field, Bonga Northwest field, is situated in OML 118. It lies at a water depth in the range of 2,953ft-3,937ft.

This field will be developed by 12 subsea wells tied back to Bonga’s FPSO.