The Breidablikk oil field (previously known as Grand) is located approximately 185km west of Haugesund on the Norwegian continental shelf (NCS) in the North Sea.

Located north-east of the Grane offshore oil field in the North Sea, the field is co-owned by Equinor Energy (operator), Petoro, Var Energi, and ConocoPhillips Skandinavia.

Breidablikk is one of the largest oil discoveries on the NCS, with estimated total recoverable reserves of approximately 30 million standard cubic metres (Sm³) of oil, which is equivalent to 200 million barrels.

The development of the field is estimated to cost approximately Nkr21bn ($1.9bn). The plan for its development and operation (PDO) was submitted to Norway’s Minister of Petroleum and Energy in September 2020 and was approved in June 2021.

The peak production from the project will range from 55,000 to 60,000 barrels of oil per day from 2024 to 2026.

Breidablikk oil field geology and discovery

Breidablikk oil field discovery was proven in 1992 and comprises the 25/11-27 (F structure) and the 25/8-4 discoveries (D structure).

A wildcat well 25/11-27 was drilled at a water depth of 130m, approximately 5km north-east of the Grane field in May 2013, to a total depth of 1,890m in the Late Cretaceous Tor Formation using the semi-submersible installation Songa Trym.

The 25/8-4 discovery (D structure) is located at a water depth of 130m, 8km north-east of the Grane field. The well 25/8-18 S was spudded for the delineation of the discovery in 2014.

The oil was found to be of excellent quality at a depth of 1,700m in the Paleocene reservoir sandstones in the Heimdal formation. The reservoir is estimated to cover an area of approximately 37km².

A seismic study of the field showed the presence of additional hydrocarbons in thinner sand zones called injectites.

Breidablikk oil field development details

The Breidablikk oil field’s development involves the installation of 22 production wells. Eight wells have been successfully drilled, with plans to drill the remaining wells by 2025.

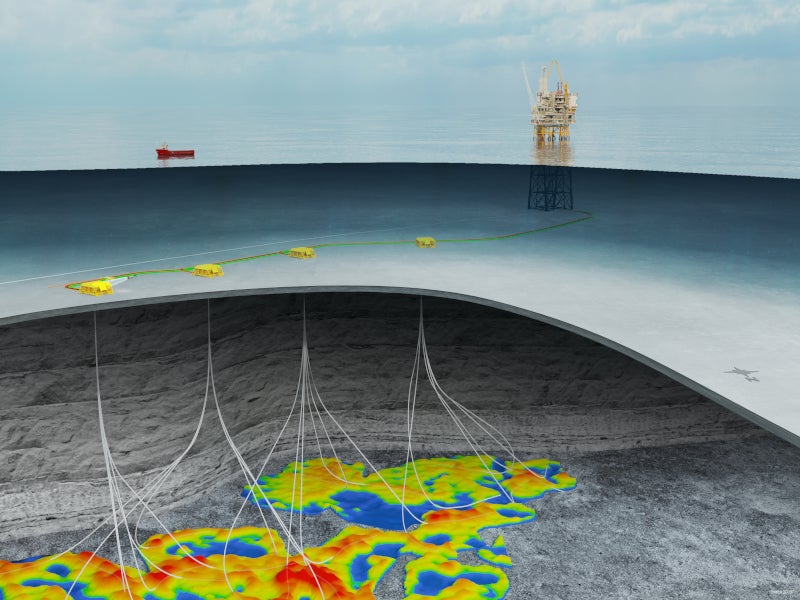

The field is connected to the existing Grane facility through four subsea templates, each accommodating six slots. Pipelines and cables have been laid between the subsea facility and the modified Grane platform to receive the well stream.

Oil extracted from the field is processed at the Grane facility and transported onshore to the Sture terminal in Hordaland County for storage and export. The project improves the recovery from the Grane area.

A total of 22 lightweight vertical subsea trees will be installed at the Breidablikk field.

Details of the Grane facility

The Grane field was discovered in 1991 and was developed with a steel-jacketed integrated drilling, processing and living facility, containing 40 slots. First oil from the field was produced in September 2003.

The Svalin field, located 8km south-west of Grane, was tied back to the Grane platform. The expected life of the Grane platform can be extended until 2060, with the start of production from the Norwegian offshore Breidablikk oil field.

Control and monitoring systems

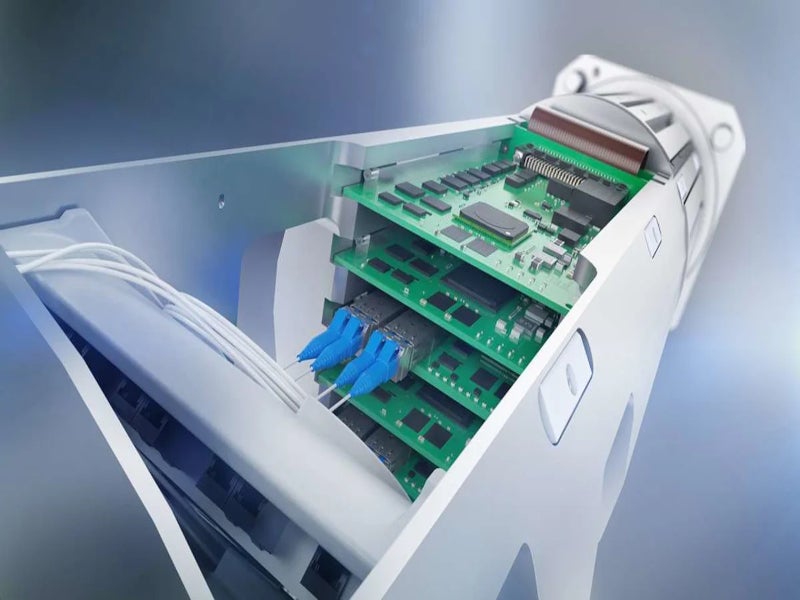

Aker Solutions’ Vectus™ subsea control system was installed at the Breidablikk field, for improved data and power capacities. It is a subsea electronics module that remotely controls the oil and production systems at the seafloor.

A control cable system for electricity and communication, known as DC/FO, allows for the use of docking stations for subsea drones on the seafloor.

Production at the Grane platform is monitored with the help of advanced digital equipment from Equinor’s integrated operations centre (IOC) at Sandsli, Bergen, for optimal production from the wells.

Contractors involved in the Breidablikk offshore project

Floatel International, an offshore flotel company, was chosen to provide flotel services for the Breidablikk project via its Floatel Superior, a semisubmersible accommodation vessel, in November 2022.

Schlumberger, an energy technology company, was awarded a contract for providing drilling services, well construction fluids, cementing, and electric wireline logging services for the project in July 2021.

Alcatel Submarine Networks, a transmission services provider, was contracted to deliver submarine cables for the project in January 2021.

Aker Solutions received a Nkr2.5bn ($260.7m) contract from Equinor to supply a subsea production system for the project in September 2020.

TechnipFMC was contracted for pipe-laying and subsea installation at the field in June 2020. Wood performed studies for the Breidablikk project and won an $84m contract in September 2020 to provide engineering, procurement, construction, and installation (EPCI) services for the modification of the topside of the Grane platform for the project.

Odfjell Drilling signed a letter of intent (LoI) with Equinor for a $290m contract for the drilling and completion of the Breidablikk project. Deepsea Aberdeen rig is used for the drilling of wells.

H. Butting, a stainless steel processing company, along with Mitsui Norway, an energy company, was contracted to deliver line pipe for the project.