Conoco brought its marginal Boulton field on-stream using the innovative SeaHarvester development concept. Its application has resulted in cost savings of up to 45% in comparison with Conoco’s broadly similar conventional unmanned platform, Ganymede.

Location

Boulton is located off the coast of Lincolnshire, approximately 170km north-east of the Theddlethorpe Gas Terminal (TGT). Developments are based upon two relatively small Carboniferous gas accumulations, lying in the UKCS block 44/21a. This block was awarded to a Conoco-led consortium in the eigth round, in 1983. The field lies in a water depth of 37m.

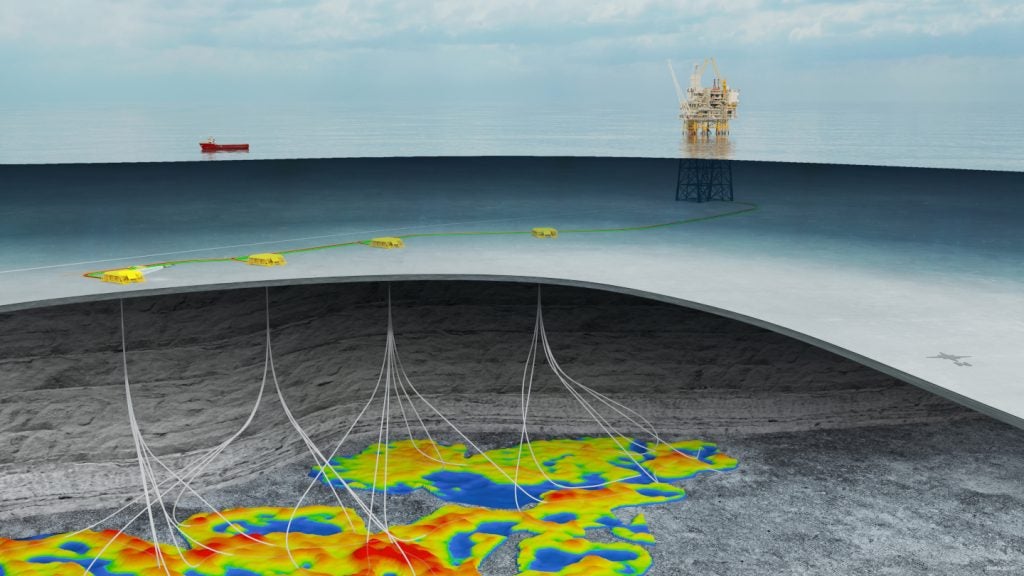

The field is initially being produced from two wells – B1 and B2. The B1 well has been drilled into the B structure; while the B2 well, drilled into the F structure, has been completed as a duo-lateral well. Total field production is expected to peak at approximately 90 million ft³/day. A field life of around 17 years is expected.

Drilling

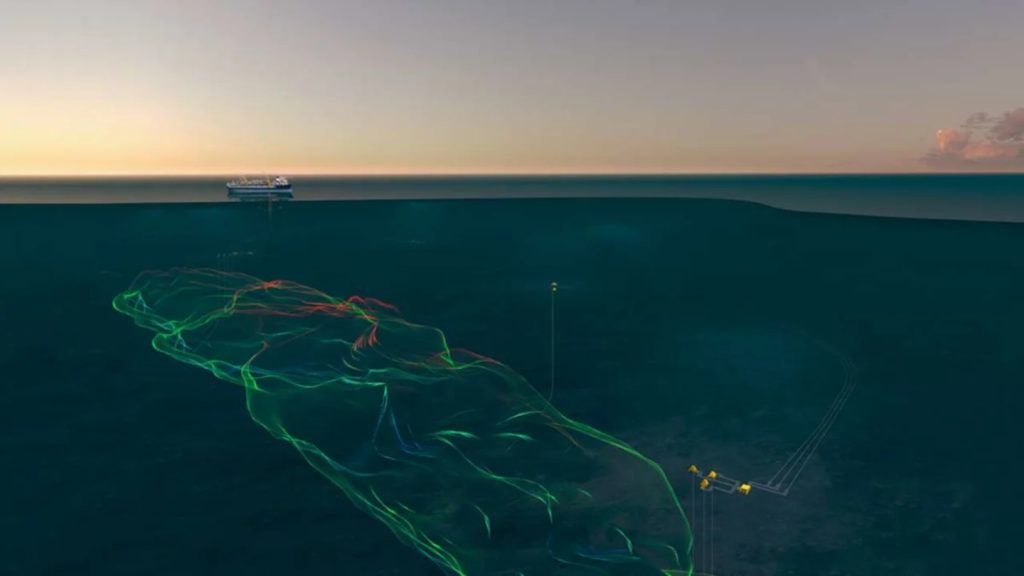

Both structures are being exploited from a single drill centre, positioned at an equal distance between the two bottom-hole locations. A subsea template was installed early on in the development, and the wells were drilled and temporarily suspended at the mudline, using the drilling rig Ensco 92. Following installation of the platform, the rig returned to tie back the wells.

These wells have total vertical depths of up to 13,000ft and stepouts of 10,000ft, giving total measured depths of up to 19,000ft. At just under four miles from the bottom-hole target, the drillers achieved an accuracy of within a circle radius of 200ft. These well trajectories were planned, to minimise drilling hazards such as the overpressure potential of the Plattendolomit formation.

Development

The field has been developed using a normally unmanned minimum facilities platform, tied back to the nearby Caister-Murdoch System (CMS) located 11km away, in Block 44/22a.

Platform

The Boulton development is based on the SeaHarvester platform design. The SeaHarvester was originally developed by the Atlantia Corporation as a standardised concept to suit typical Gulf of Mexico conditions. To obviate the traditional costs of purpose-designing each platform, the SeaHarvester is designed to be bought ‘off the peg’ and merely modified to suit each specific application. Over 60 such structures have been installed. These have handled up to eight wells, producing up to 300,000 barrels/day.

Boulton is the first of such a platform in the UK. The fabrication was carried out as an EPIC contract, by Odebrecht-SLP Engineering, in Lowestoft. The platform fabrication and installation was carried out in just ten months.

Jacket

The jacket is only 463t (installed gross) in weight and 57m high. It consists of a four-legged vertical (Vierendeel) tower that penetrates the water surface. From this tower, the topsides are supported by four spider braces that prop the four deck-support points.

Below the water level, the Virendeel tower is held by raking bracings, which connect it to the top of a K-braced parallel-sided box. This box incorporates four support piles, grouted into the four outer legs.

Up to four production well conductors are run inside the four leg columns, to give the wells physical protection and minimise wave loading. The legs are thickened and braced at 4.2m intervals.

Topsides

The deck weight is 337t (installed weight gross). The process-related equipment is limited to individual well control and wet gas metering. The production manifold includes a high-integrity production system (HIPS), to protect the lower-pressure-related interfield pipeline.

To save on weight, no test separator or water knockout system have been included on the platform. Within the process train, each well is monitored separately by the Venturi meter.