The Britannia field, discovered in the mid 1970s, is the first in the UK sector of the North Sea to be operated jointly by two companies, Conoco and Chevron, through the formation of the new operating company, Britannia Operator Limited.

Britannia, situated 210km (130 miles) north-east of Aberdeen, covers approximately 112km² (70m2).

The subsea facilities are located on the seabed in 150m of water and produce approximately 25% of Britannia’s reserves. Located 15km west of the platform, the subsea centre consists of a manifold adjacent to seven pre-drilled production wells. The manifold (33m long x 16m wide x 9m high) can handle gas and associated liquids from up to 14 wells, and is designed to produce up to 380,000,000ft³ of gas per day.

The manifold is linked to the platform by a series of flowlines, grouped together and surrounded by a 37in-diameter carrier pipe to form a flowline bundle. The carrier pipe provides a hot-water jacket to prevent hydrate and wax formation, as the gases and liquids travel from the subsea centre to the platform. The flowline bundle will be fabricated and towed 300km to the North Sea site, in two separate pieces, each 7.5km long.

The flowline bundle is the longest ever fabricated and the first to utilise the carrier pipe as a novel heating device, to prevent hydrate formation in the production line. Hot water is pumped from the platform to the manifold before it flows back, in a closed loop, through the carrier pipe. The subsea system is controlled from the platform, via two 15km flexible umbilicals, buried in the seabed on either side of the flowline bundle.

Substructure

The eight-legged tubular-framed substructure supports the topsides, risers and caissons, and is located over the ten-slot well template, which was installed in 1995. Large mudmats were required to support the substructure’s 20,700t weight, while the 20 foundation piles were driven 105m into the seabed using underwater hammers. At 123m in length (400ft) and 2.74m (9ft) in diameter, these are the largest piles in the history of the North Sea. The jacket is 158m tall and its base is 78x70m.

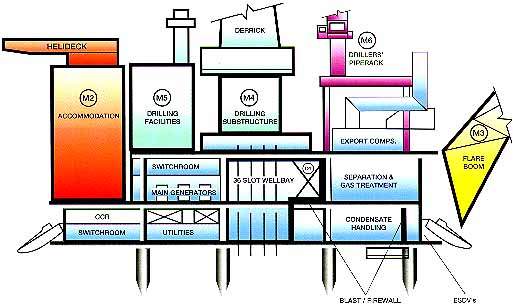

Topsides

The seven major components comprising the platform topsides were built in Lowestoft and Teesside. These contain utility, drilling and production facilities, together with a 140-man accommodation unit. The heaviest unit is the integrated deck, weighing 11,000t, which required maximum use of the lift (this was one of the largest semi-submersible crane vessels available).

Export pipelines

Gas from Britannia is processed at the Scottish Area Gas Evacuation (SAGE) terminal in St Fergus, which handles gas produced from a number of other North Sea fields.

Special attention has been given to the landfall, which occurs in an environmentally sensitive area of high dunes and a freshwater loch. Condensate is exported via a new 44km (27-mile) pipeline, to the existing Forties pipeline system and tanker-loading facilities, at Hound Point, in the Firth of Forth.

Subsea facilities

The 750t subsea production manifold has 14 slots and is located 15km away from the platform. A heated flowline bundle runs to platform and remote control from the platform is made possible by two electro-hydraulic umbilicals. Provisions for future expansion include the possible tie-in of a remote satellite well cluster from the west, and the future tie-in of an additional cluster, located mid-line.

Export pipelines

The design and engineering of export pipelines includes a 14in-diameter pipe, for exporting condensate to the Forties Unity Platform and Forties Pipeline system. Gas export is through a 27in-diameter, 180bar line to St Fergus.