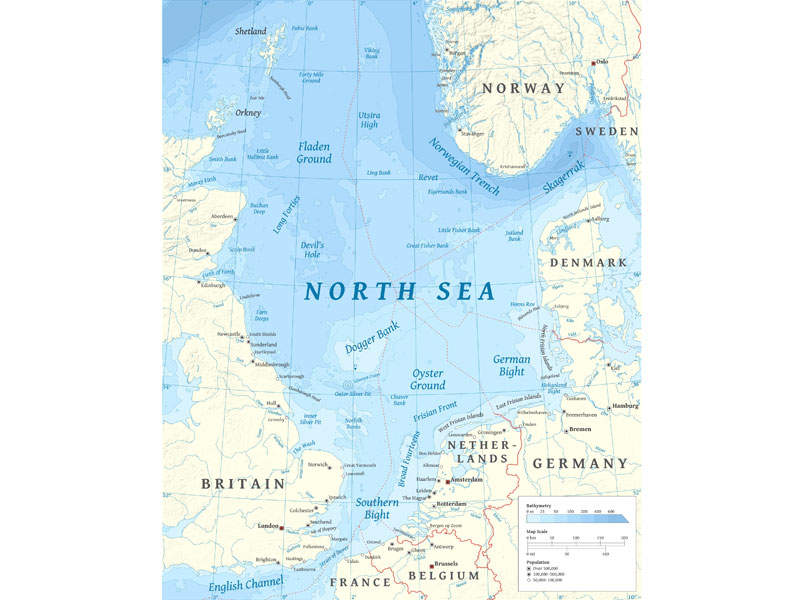

Callater field, formerly known as prospect K, is located in block 09/10b of the UK North Sea, approximately 335km north-east of Aberdeen.

The block is jointly owned by its operator Apache Corporation (55%) and the Shell Corporation (45%).

The field commenced initial production in August 2017 and is currently producing at a rate of 14,000 barrels of oil equivalent a day (boed).

Callater field discovery

Callater field was discovered by the 9/19B-18 well in June 2015.

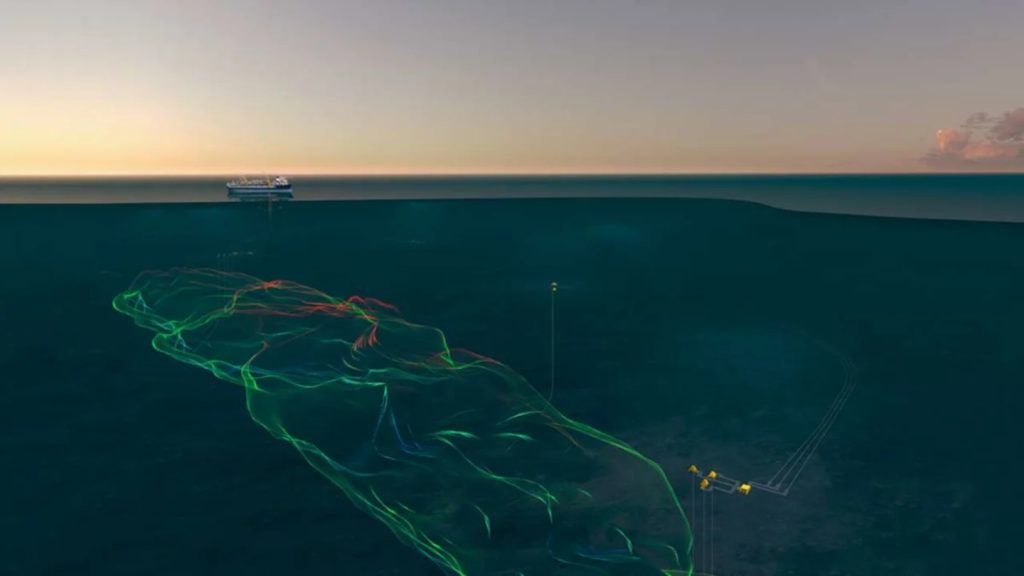

The well encountered more than 1,500ft of high-quality, oil-bearing sands of the Beryl, Linnhe, Nansen and Cormorant formations in three fault blocks.

Two sidetracks have also been drilled into nearby fault blocks in the Beryl formation.

Reserves and geology of Callater

Callater is a Jurassic-age field, which is estimated to have a life between eight and 13 years.

It contains oil and gas in the ratio of 40:60.

The field is estimated to contain 45 million barrels of oil equivalent (boe).

Callater field development details

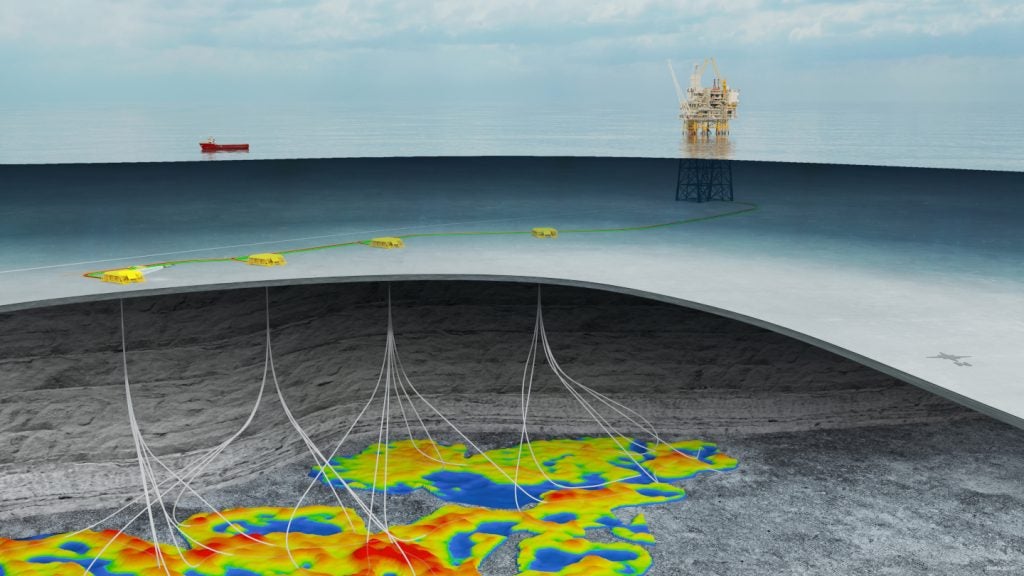

Callater was developed as a tie-back to the Beryl Alpha platform through the Skene field’s subsea facilities.

The subsea development required the expansion of the platform’s processing capacity.

A 220t six-well manifold was installed at the field in support of the initiative, along with a 120t tie-in manifold at Skene.

A 3.9km-long pipeline bundle transports produced hydrocarbons from the Callater manifold to the Skene manifold.

The hydrocarbons are then exported to the Beryl Alpha platform.

The pipeline bundle consists of a 45in pipeline system containing production lines, flow and return hot water heating lines, as well as power and supply components.

In addition, the 12.7km-long electrical control umbilical and associated systems were also installed to link the platform to the field.

All of the development’s wellheads and subsea Christmas trees are equipped with protective structures.

An estimated 11,750t of rock dump was required to protect the control umbilical.

Furthermore, 150 concrete mattresses were installed to protect the subsea well locations, manifolds and the pipelines.

Several modifications were also carried out on the Beryl Alpha platform. These included renovations to the fire and gas safety system to enable early detection of irregular situations such as fires.

Beryl Alpha platform

The Beryl Alpha platform is a gravity-based structure installed in 117.5m of water in Block 9/13a of the UK North Sea.

It includes a bridge-linked, four-legged Riser Access Tower and bridge-linked flare tower.

The platform is equipped with risers for flowlines, which connect a number of subsea wells in the Beryl area.

It also features gas import risers and gas export riser to the SAGE pipeline.

Beryl Alpha platform is jointly owned by Apache Beryl I (60.56%) and Enterprise Oil (39.44%).

Contractors involved

Subsea 7 won the engineering, procurement, installation and commissioning (EPIC) contract to supply the pipeline bundle system, which was used to connect the field to the Beryl Alpha platform.

James Fisher Offshore assisted Subsea 7 in the umbilical installation.

Servelec Controls was contracted to carry out modifications to Beryl Alpha platform’s fire and gas safety systems.

Proserv won a contract to supply four subsea control systems and related equipment.

The systems are intended to provide compatibility with the already-installed equipment and allow for the future tie-backs of nearby fields.

Future plans

A third well known as CB-1 was drilled into a new fault block and encountered more than 260ft of net pay.

The well was placed on production towards the end of November 2017.

Additional wells are planned to be drilled based on the performance of the field and the economic viability of production.