The Foinaven oilfield is located in blocks 204 / 19 and 204 / 24a, which are operated by BP Exploration. Shell UK Exploration and Production is the co-venturer.

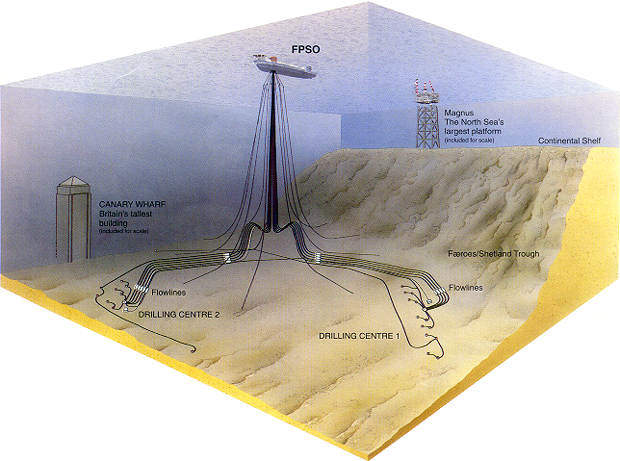

These blocks lie 190km west of the Shetland Islands, in a water depth of between 400m and 600m. Recoverable reserves are estimated to be in the region of 250 million-600 million barrels of oil.

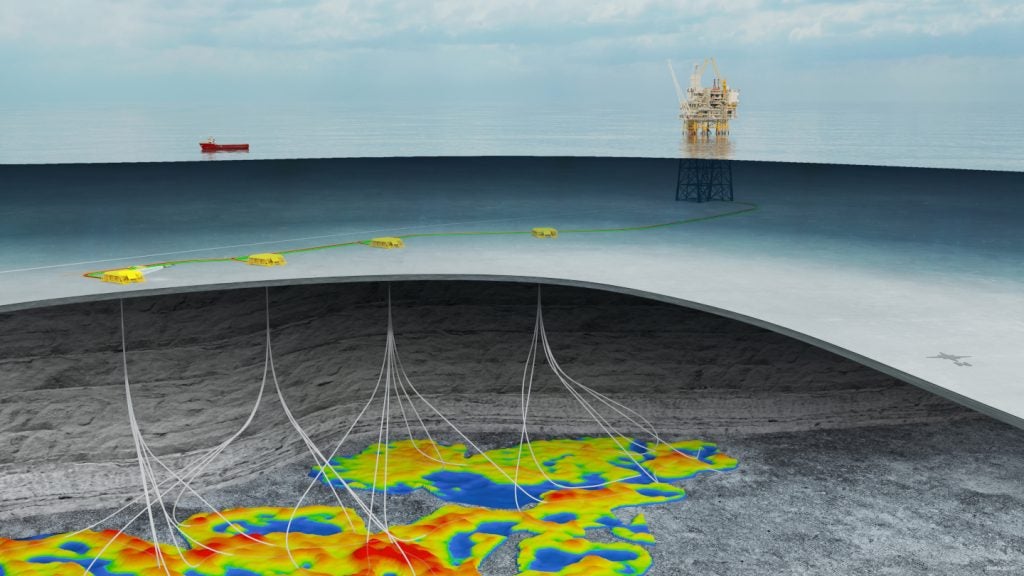

The Foinaven project was carried out as a phased development. The first of these were based on the recovery of 200 millions barrels within Foinaven. These developments centre on subsea wells completed on the seabed. They produce oil, via a manifold, which passes through rigid flowlines and then flexible risers into a floating production, storage and offloading system (FPSO), which is permanently stationed in the field. Shuttle tankers then export the crude oil.

Foinaven development

The development of the Foinaven oilfield began when the first satellite field was sanctioned in 1999. The sanction was made as a single well development.

The drilling over this was completed in mid-2000 and the field was then brought onstream.

During the same year BP received the approval to go ahead with the second phase of development of the field, which consisted of four production wells and a water injection. This phase was completed in 2002.

Technology and drilling

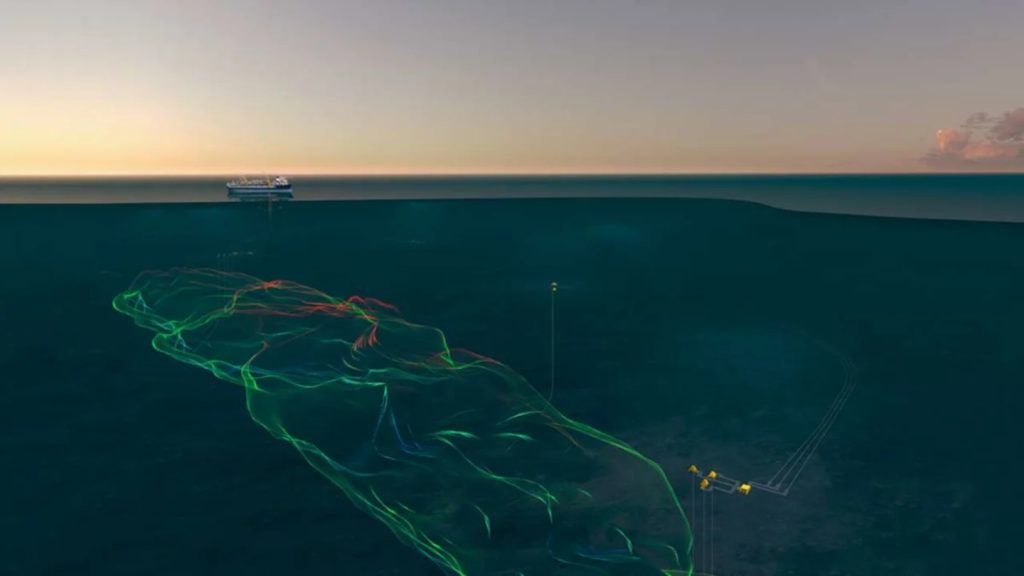

Horizontal drilling is a technology that has undergone radical developments since the early 1990s. BP and Shell have successfully used this type of drilling in other projects.

Horizontal wells expose a larger section of the reservoir to the well bore, resulting in increased flow rates. For Foinaven, the low rock strength of the oil-bearing sands necessitates the installation of pre-packed screens. Horizontal sections in excess of 1,500m are possible.

The selection of horizontal wells for Foinaven has reduced the number of production wells required to 14 from 28. Water and gas-injection wells are also required.

Drilling wells in 500m of water with changeable currents can create problems because the water depths are beyond those in which divers can operate. Therefore, the costs associated with the development of the subsea gathering scheme are high.

For the first time in a BP-operated offshore environment, some of the producing wells are multilateral, with two wells or more sharing the same well bore, with oil flowing through each one.

FPSO Petrojarl IV

Foinaven’s FPSO Petrojarl IV was built in Finland by PGS Production by converting Anadyr, a Russian submarine tender ship. The vessel underwent a major rebuilding programme involving the removal of the bow and stern, which were upgraded and attached to a new mid-section of a double-skinned hull, thereby increasing its length to 240m.

The FPSO has the capacity to process up to 95,000 barrels of oil per day and to inject 165,000 barrels of water per day into the reservoir. Gas lift and re-injection were available from first oil.

The vessel’s ten anchors enable it to maintain stationary, even in the most severe weather conditions. The anchor wires, and up to 15 flexible risers and control umbilicals reach the surface inside a turret. The vessel ‘weathervanes’ around this turret, under the influence of the wind, waves and currents, with thruster assistance to aid station-keeping.

Shuttle tankers visit approximately every three days during peak production periods and storage for some 300,000 barrels of produced oil are available onboard the FPSO.

Subsea at Foinaven

Foinaven’s subsea layout comprises four drilling centres, each based upon a manifold and well cluster arrangement with rigid steel flowlines connecting to the riser-base locations, flexible risers connecting the riser bases to the FPSO vessel, as well as the associated control system umbilicals.

Innovative diverless connectors (DMaC) were used for the subsea installation and hook-up.

At Drilling Centre 1 (DC1) there are eight production wells, four water-injection wells and up to two gas-injection wells. Drilling Centre 2 (DC2) has six production wells, with three remote water-injection wells. These drilling centres are located approximately 3.5km from the FPSO vessel: one to the north, the other to the west.

Drilling Centre 3 (DC3) has a single gas disposal well and Drilling Centre 4 (DC4) has two wells.

All drilling facilities are performed by semi-submersible drilling rigs.

Pipelines

The common flowlines running from each drilling centre to the riser-base locations are:

- Two 10in production flowlines

- Two 8in production/test flowlines

- One 8in gas-injection/gas-lift flowline

The gas produced at Foinaven is exported via a 20in-diameter pipeline. Laid in 2000, the pipeline links the Foinaven field with the Schiehallion and Magnus fields via Sullom Voe terminal.

The western leg of the pipeline extends over a length of 198km from Foinaven to Sullom Voe via Schiehallion. The eastern leg of the pipeline is 210km long and extends from Sullom Voe to Magnus. The pipeline can carry a maximum of 190 million cubic feet of gas per day.

The first gas export through the pipeline was made in mid-2002.