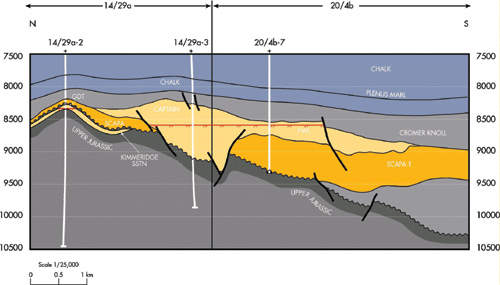

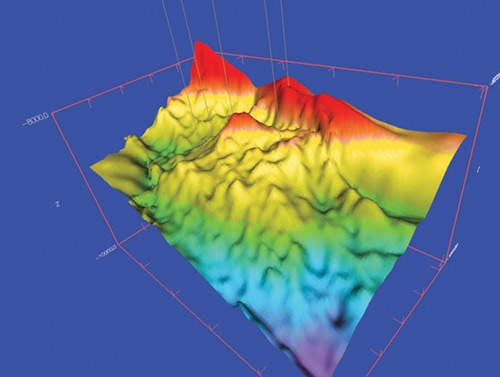

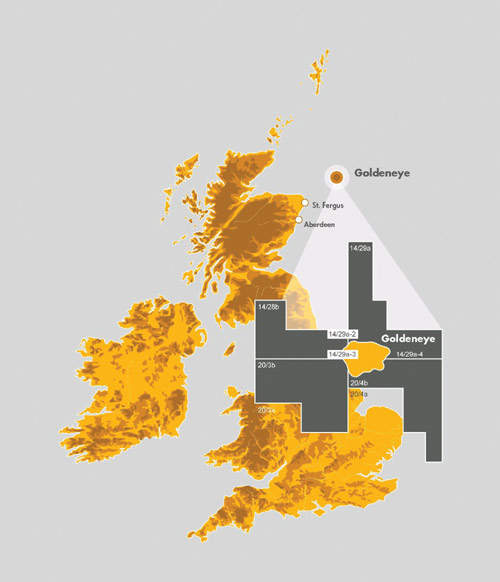

Goldeneye is located 100km northeast of St Fergus. It was discovered in October 1996 with the drilling of well 14/29a-3 in the South Halibut Basin of the Outer Moray Firth. The majority of the reserves lie within block 14/29, although the field extends into blocks 14/28b, 20/30b and 20/4b.

Goldeneye is operated by Shell (52.5%) on behalf of:

Esso: 39%

Lasmo: 4.5%

Paladin: 3%

Veba: 1%

The area around Goldeneye is devoid of suitable gas processing infrastructure, and early evaluations of traditional concepts to process gas and condensate offshore proved uneconomical. However, the relatively close proximity to the St Fergus shore-based processing facilities, coupled with the composition of the gas condensate mixture and market requirements for a steady and predictable gas supply, offered a unique opportunity to evaluate alternative concepts.

Instead of offshore processing, the Goldeneye wellstream will be produced through a small platform and piped back to shore and routed into a new processing module onshore at St Fergus. At 105km, the Full Wellstream Transfer pipeline will be the longest tieback in the UKCS, transferring gas and condensate under reservoir pressure from the unmanned platform on the field.

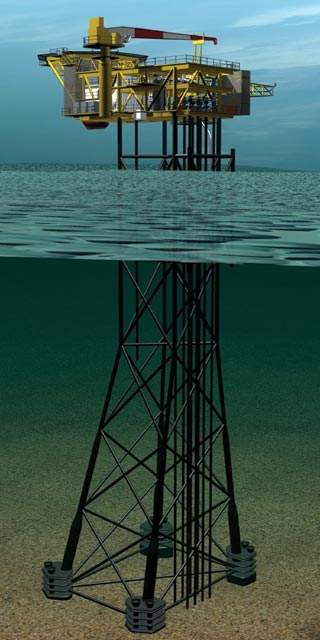

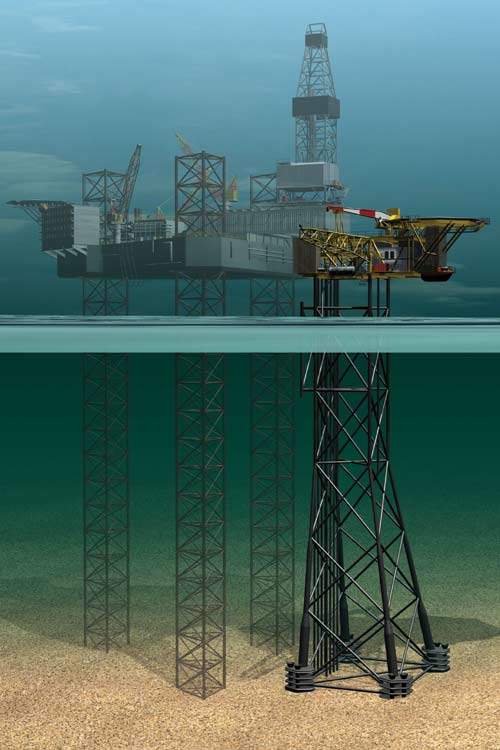

The offshore facility will be a Normally Unattended Installation (NUI), with no planned production water discharge, utilising reservoir energy to drive the Full Well-stream Transfer to shore rather than compressors. The platform will consist of a four-leg piled steel jacket weighing 3,500t anchored by eight piles totalling 2,500t. This will support a 1,000t topsides, which will include wellhead/MEG injection equipment as well as detection, measurement and control facilities. The platform contains twelve-man overnight accommodation as well as a lifeboat and safety equipment. It has both a crane and helideck.

JACK-UP DRILLING RIG

The reservoir is in lower cretaceous Captain sandstone and is capable of high rates of production – more than 100mmscf/day/well. In total five wells will be drilled using a harsh environment deep water, three-leg, jack-up drilling rig, operating in 120m of water. This will mark the UK’s greatest water depth in which a jack-up rig has been used for production drilling. Goldeneye will be produced from wells deviated into the reservoir. They will have a true vertical depth of 8,300ft and a measured depth of between 9,000ft and 15,000ft.

EXPORT

The wellstream will be routed to shore by a 20in gas condensate line to the St Fergus plant. There will also be a 4in MEG service line to platform. Both pipelines were installed simultaneously on the seabed along a route parallel to the existing Miller pipeline, thereby avoiding further restrictions on fishing operations.

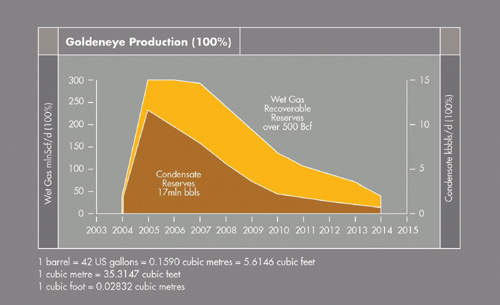

Goldeneye plateau production will be 300mmscf/d wet-gas and 10,000b/d condensate. Natural Gas Liquids (NGLs) will be extracted from the gas and condensate streams throughout field life. The field is expected to be in production from 2004 for between seven and ten years. Onshore processing will utilise power from the National Grid instead of offshore generators, resulting in very low CO2 emissions compared to a conventional platform.

ONSHORE PROCESSING

Gas will be delivered to the National Transmission System at Transco in St Fergus, while NGLs and condensate will go to the Fife Natural Gas Liquids Plant in Mossmorran through an existing pipeline. After further processing various products, including condensate, Propane and Butane will be available for entry into the European petrochemical and refinery markets.