Hibernia is located in the Jeanne d’Arc Basin, 315km east of St John’s, Newfoundland and Labrador, Canada, in a water depth of 80m. The field consists principally of two early Cretaceous reservoirs, Hibernia and Avalon, located at average depths of 3,700m and 2,400m respectively.

Hibernia oil is a light sweet crude with a density of 32°-34° API and a sulphur content by weight of 0.4% to 0.6%. The field contains approximately three billion barrels of oil-in-place and recoverable reserves are estimated to be at approximately 1,200 million barrels.

The Hibernia field was first discovered in 1979. Development began in 1986 and construction started in 1991.

The field started production in November 1997 and by 2009 its total crude oil production was 126,000 barrels per day (bpd). The field generated 667 million barrels by the end of 2009.

The Hibernia field is operated by ExxonMobil and owned by Norsk Hydro (5%), Murphy Oil (6.5%), Canada Hibernia Holding Corporation (8.5%), Suncor (20%), Equinor Canada (5%), Chevron Canada Resources (26.875%) and ExxonMobil Canada subsidiary (33.125%).

In February 2010, the developers signed an agreement with the Government of Newfoundland and Labrador for the Hibernia Southern Extension project. The agreement granted a 10% stake to the Canadian Government through its Nalcor Energy.

Production from the Hibernia field was briefly halted in August 2019 following a second oil spill in a month. It was resumed in October 2019.

Development of Hibernia

It was decided that the Hibernia field would be developed using a special gravity-based structure strong enough to withstand a collision with a one-million-tonne iceberg (expected to occur once every 500 years) and a direct hit from a six-million-tonne iceberg (expected just once every 10,000 years).

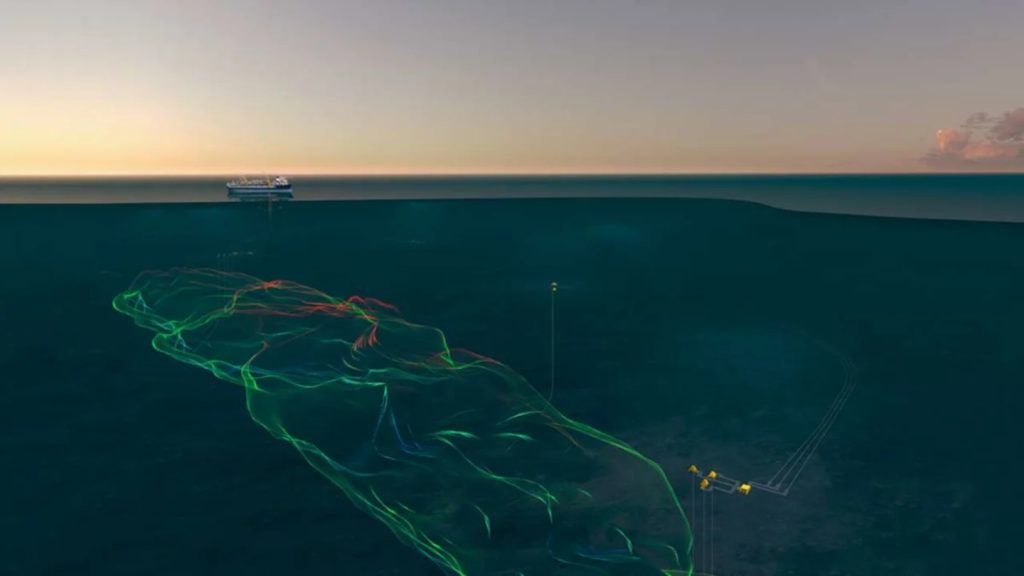

About 50 development wells were successfully drilled in Hibernia by January 2007. By that time, the total investment in the development was $5.8bn.

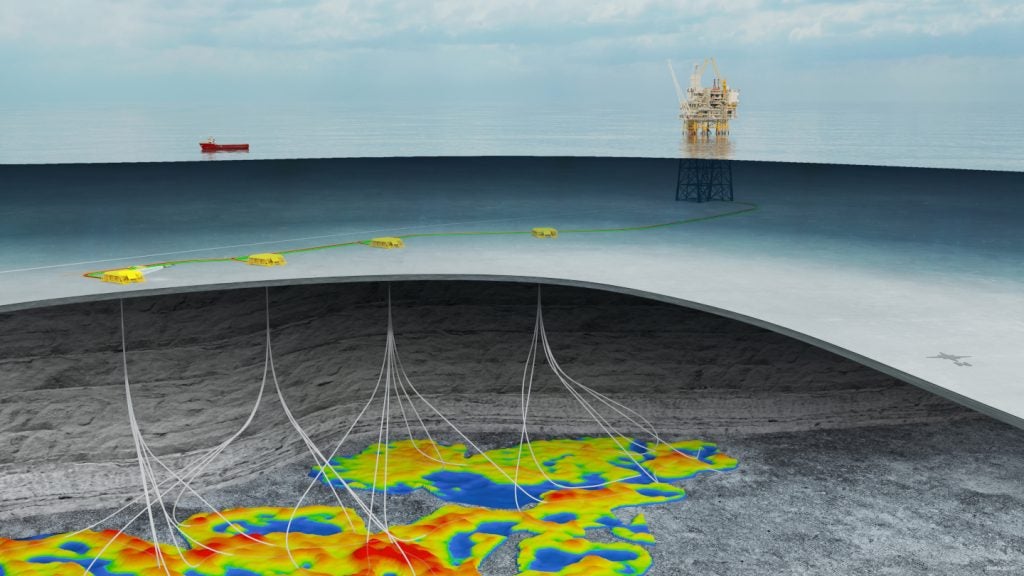

The field partners for the Hibernia Southern Extension at the time comprised ExxonMobil Canada (27.9%), Chevron Canada (23.7%), Suncor (19.2%), Statoil (9.3%), Nalcor Energy (10%), Canada Hibernia Holding (5.6%) and Murphy Oil (4.3%). The Hibernia Southern Extension is developed with tiebacks to the Hibernia platform and included up to five platform drilled production wells and up to six water injection subsea wells. First oil from the Hibernia South Extension Unit KK well was achieved in June 2011.

Gravity-base structure of Hibernia field

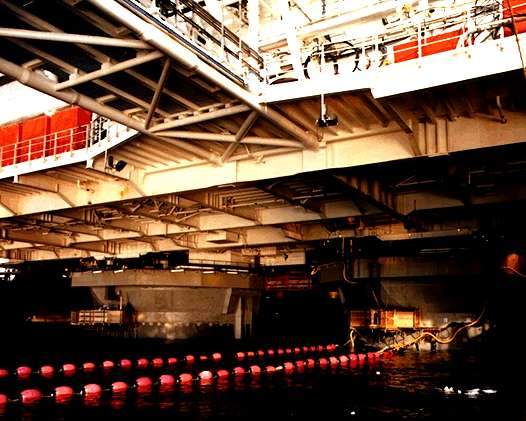

Hibernia’s novel 450,000t gravity-base structure design consists of a 105.5m concrete caisson, constructed using high-strength concrete reinforced with steel rods and pre-stressed tendons. The caisson is surrounded by an ice wall, which consists of 16 concrete teeth.

Structurally, the 1.4m-thick ice wall is supported by a system of X and V walls, which transmit the loads to the interior tie wall. The X and V walls have a thickness, varying from 0.7m to 0.9m and the tie wall has a thickness of 0.9m. The walls form the ice belt.

The caisson is closed at the bottom and top by horizontal slabs and the base slab has a diameter of 108m. The upper top-surface slab is approximately 5m above sea level.

Storage tanks for 1.3 million barrels of crude oil relocated inside the gravity structure. Four shafts run through the GBS from the base slab to support the topsides facilities, including the utility, riser and two drill shafts. Each shaft is 17m in diameter and extends to a total height of 111m.

The utility shaft features the mechanical outfitting required to operate the GBS system. It includes pipework, heating, air-conditioning and electrical controls.

The two drill shafts each have 32 drill slots to accommodate the wells, which will reach depths of more than 3,700m below sea level, down into the oil reservoirs.

Topsides

The topsides have a design capacity of 23,900m³ per day (150,000bpd), based on the 98 million cubic metres (615 million barrels) estimate. The topside facilities consist of five super-modules (processing, wellhead, mud, utilities and accommodation for 185 people), as well as seven topside-mounted structures (helideck, flare boom, pipe rack, main and auxiliary lifeboat stations and two drilling modules).

The wellhead module for Hibernia was fabricated at Bull Arm while the remaining components were made in construction sites located around the world, including two in Italy and the remaining two in South Korea. Four of the topside mounted structures (flare boom, helideck, main and auxiliary lifeboat stations) were also fabricated at Bull Arm.

The other three topside-mounted structures (components of the two drilling rigs and the pipe rack) were fabricated in Newfoundland and New Brunswick, with some of the components being built in Alberta.

Mating

The 37,000t integrated topsides facility was transported by barges to the Hibernia deepwater site and positioned above the partially submerged GBS shafts to form the completed 600,000t production platform.

It was then towed to its final site and 450,000t of solid ballast was added to secure it in place.

Offshore loading system

Oil stored in the GBS is exported by means of an offshore loading system (OLS) consisting of subsea pipelines, a subsurface buoy and flexible loading hoses, feeding a purpose-built shuttle tanker.

The other infrastructure supporting the field production include platform support facilities, shore base facility, Asco Warehouse Complex warehouse facility, transhipment terminal and a remotely operated vehicle.

Contractors in Hibernia oil and gas field project

In April 2011, FMC Technologies was awarded the contract to supply subsea equipment for the Hibernia Southern Extension project. Deliveries are scheduled to commence in the third quarter of 2013.

In May 2011, Technip won the contract to design, manufacture and install a flexible flowline and steel tub umbilical for the Hibernia Southern Extension project.

In September 1990, HMDC awarded the gravity-base structure (GBS) contract design to Newfoundland Offshore Development Constructors (Nodeco). The detailed design was subcontracted to Doris Development Canada (DDC).