The high-pressure / high-temperature Jade field is located in block 30 / 2c of the UK North Sea, 17.7km north of the Judy project.

The field was discovered in 1996 and confirmed by an appraisal well in early 1997.

Jade tested at a combined rate of 91 million cubic feet of gas per day and 9,700 barrels (bbl) of condensate per day.

The production plateau rate is approximately 188 million cubic feet of gas per day and 16,000 barrels per day (bpd).

ConocoPhillips is the operator of Jade and holds a 32.5% interest, while the project’s co-venturers are BG (35%), Texaco (19.93%), Agip (7%) and OMV (5.57%).

Jade produces a light paraffinic condensate, which has a 3.0% CO2 content and 25 parts per million (ppm) of H2S.

Jade’s wax content (wt%) is 19.1wt%-23.8wt%. It has a wax cloud point of 50°C and a dead oil pour point of 12°C.

One of the two appraisal wells was completed as a producer, while the other was for the cuttings injection.

In addition, three wells were drilled over the platform by the harsh environment, deepwater jack-up Galaxy II, in cantilever mode. The field came onstream in 2002.

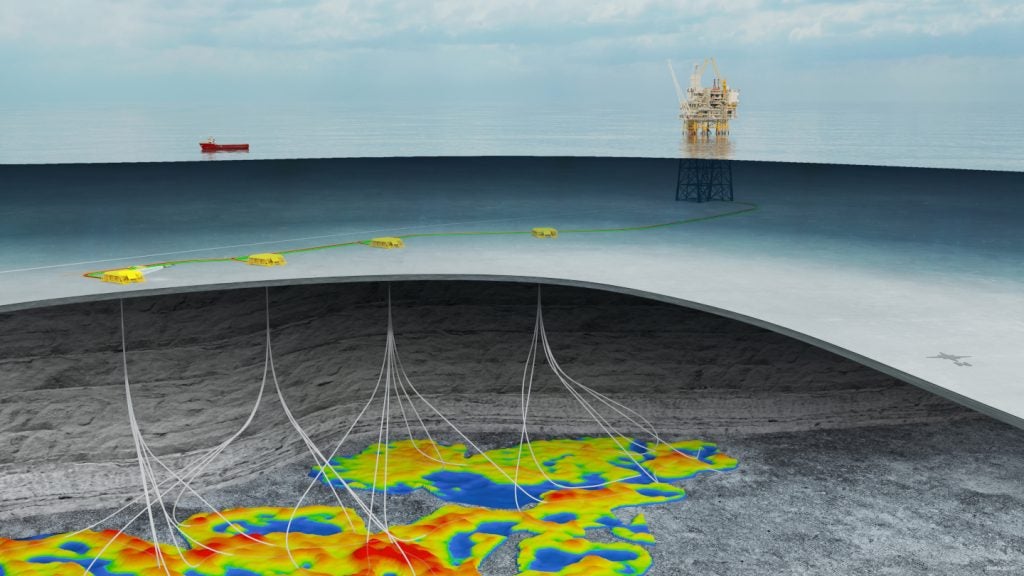

Jade was developed by a normally unattended installation, tied back to Judy.

Jade has been producing from seven wells as of 2008.

The aggregate production from the field along with Judy and Joanne was 336 million standard cubic feet per day (Mmsfcd) and 26,900 barrels of oil per day (bopd) in 2008.

Amec carried out the detailed design as an extension of the conceptual design. The Jade platform has a design life of 20 years.

Jade jacket

The jacket has a four-leg vertical-sided twisted-base design. It was built by Kvaerner at Methil, Scotland. The tower structure measures 28m x 28m.

Approximately 30m from the base, there is a 45° turn afforded by a Y-joint, enabling the tower to sit in a base of 38.6m².

The jacket was installed in a tandem lift by the crane barge S 7000 and then positioned over the subsea well-spacer frame.

It was then secured using four piles, weighing 1,100t.

Topside detail

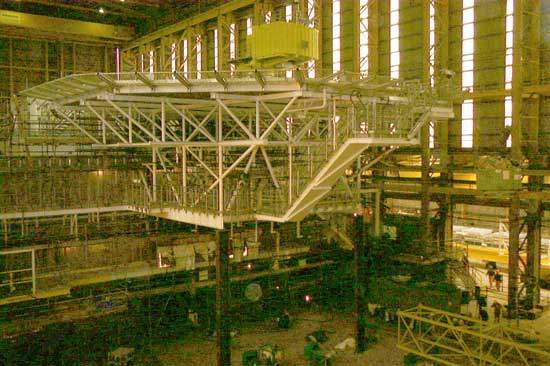

The topsides have been built by Heerema in Hartlepool. The design is based on a three-deck structure, comprising a weather deck, mezzanine deck and main deck.

The deck measures 45m x 35m and there is an 8m vertical separation between decks.

The topsides have a lift weight of 2,000t and a gross-operating weight of 4,700t.

For safety, there is a blast wall separating the wellhead from the utility area and another blast / firewall on the accommodation unit.

There is also a fire pump and a TEMPSC lifeboat.

Power is provided by dedicated packaged diesel generator sets, located on the outside of the platform for easy access.

There are two duty and one standby / emergency sets, with a fourth spare located onshore.

Platform access is via an aluminium helideck. To assist in platform operations there is a pedestal crane with a 36t lift capacity.

The fully pressure-rated topsides and piping are designed to accommodate a 160°C flowing wellhead temperature and a 11,000psi wellhead-design shut-in pressure.

The pipeline design pressure is 150bar. There is also a high-integrity pipeline pressure system for protecting the pipeline.

Upstream from the wellheads are chemical-injection facilities for methanol, wax, corrosion and scale inhibitors.

All diesel and chemical storage sets have been designed for 60-day replenishment cycles. Temporary accommodation is provided by a 12-person unit.

Link to Judy

Jade is linked to Judy via a 16in pressure-containment pipe in a 20in carrier pipe. To avoid pipeline expansion from the heat, eight loops are installed with straight sections buried between the sites.

Modifications made to Judy include the installation of a new riser and valves, and the re-allocation of the existing pre-Cretaceous HP separator train.

From Judy, gas is transported through the CATS pipeline to the CATS terminal in Teesside.

Oil is taken through the Norpipe pipeline up to the Phillips Seal Sands terminal.