The Malampaya field is located 80km off the coast of Palawan Island, in the Republic of the Philippines.

In August 1998, Shell Philippines Exploration BV awarded Brown & Root a $432m design, procurement, fabrication, installation and commissioning contract.

Shell Philippines Exploration BV is the project operator. The joint venture partners in the project are Chevron Malampaya LLC (45%) and PNOC Exploration Corporation (10%).

Malampaya project was developed and is being operated by Shell Philippines Exploration on behalf of the joint venture partners.

Philippine Department of Energy led the development. In October 2001, the project was inaugurated at the onshore gas plant in Batangas.

The platform consists of a deck, supported by a concrete gravity sub-structure (CGS).

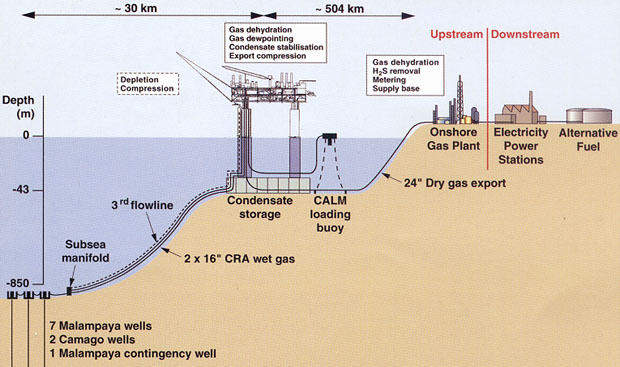

Processed gas is compressed and exported through a 504km pipeline to the Batangas onshore facility at Luzon Island, in the Philippines.

Condensate is stabilised on the topsides, stored in the CGS and then exported to a shuttle tanker through a catenary anchored leg mooring system, located 3km from the platform.

The design capacity of the integrated CGS and deck is 508 million cubic feet gas and 32,800 barrels (bbl) of stabilised condensate per day.

The platform is located in water 43m-deep and the deepwater subsea wells are at a depth of 850m.

Field development

The field was developed using a manifold cluster of subsea wells tied back to the platform.

The manifold comprises a three-pile foundation and was installed with the assistance of a spacer template, a manifold support structure, tie-in porches for ten cluster wells, three umbilicals, three flowlines and a retrievable manifold consisting of three header ball valves and ten gate valves.

Topside details

The topsides were subcontracted to Sembawang Marine & Offshore Engineering (SMOE).

The contract involved the fabrication, onshore commissioning and load-out of a three-level integrated deck, together with an accommodation module for up to 44 people.

Topsides measure 40m x 90m in plan and reach 25m from the base of the cellar deck to the helideck. The lower (cellar) deck contains the major pumps, heavy wall vessels and workshops.

Middle deck, or production deck, contains the separation equipment and the electrical-control module.

Equipment on the top deck, or weather deck, includes two export gas compressors, three power-generation gas turbines and a crane.

The initial operating weight of the topside was 13,000t. This equated to a load-out weight, excluding the transportation frame, of 10,000t, and was the heaviest topside ever constructed by SMOE at that time.

Fabrication of the deck commenced at Sembawang’s yard, located in the north of Singapore, in June 1999. It was completed on schedule in 2001.

Concrete gravity sub-structure

Topsides sit on a concrete gravity sub-structure (CGS), the first to be constructed in the Philippines.

Brown & Root subcontracted the work to the Malampaya CGS Alliance, which consisted of John Holland, Arup Energy and Van Oord ACZ, for the engineering, procurement, construction and installation of the structure.

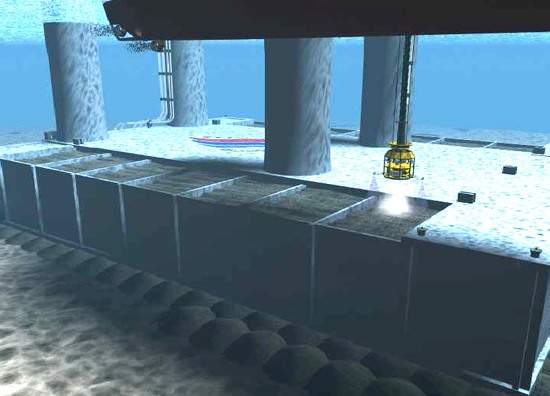

CGS consists of a rectangular-based caisson, measuring 112m x 70m on plan, which is 16m-high.

It has four shafts extending 15m above water level to provide support to a deck with an operational weight of 13,000t.

In addition to providing deck support, the CGS is used for the temporary storage of up to 385,000bbl of condensate, produced from the subsea wells located 30km away.

CGS subcontract was the single biggest value subcontract placed by BRES at that time under its Malampaya platform contract.

CGS was constructed in a purpose-built dry-dock located in Subic Bay.

In total, the CGS required 66,000t of concrete, 7,100t of reinforcing steel and 600t of pre-stressing steel strands.

CGS was placed on a pre-prepared foundation to accommodate the unevenness of the seabed.

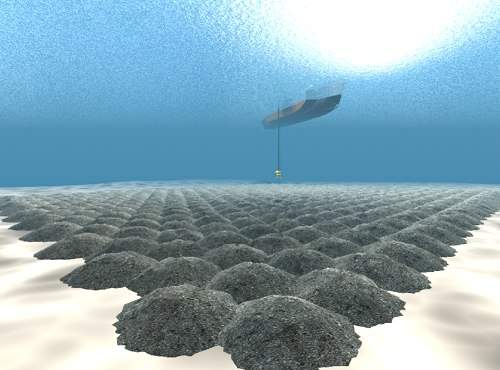

This involved placing 17,000t of rock in 361 mounds on the seabed. To allow access to the open sea, a channel 150m-wide and 12m-deep was dredged.

After installation, 3,000t of rock was placed around the corners of the CGS for scour protection and 75,000t of iron ore was placed in the open cells.

The structure was installed three months before schedule although the storage system was changed from wet to dry.

The concrete structure was completed by March 2000 and the deck was installed in March 2001.

In December 2001, an extended well test of the thin oil rim beneath the field initially yielded about 8,000 barrels per day (bpd).

The well test was performed by the Atwood Falcon drilling rig and Stena Natalita floating storage unit.

It is also believed to be the deepest horizontal subsea well test undertaken in the world at a depth of about 850m.

Malampaya contracts

Transfield Services WorleyParsons was contracted to offer integrated services at the gas facility.

Awarded in December 2009, the A$76m contract was for seven years starting from January 2010, with a provision to extend for another three years.

The contract for design and supply of subsea production manifold for the project was given to Cooper Cameron.

Intecsea supported Cameron with systems engineering for subsea development of the project, along with other engineering works and selecting a final pipeline route.