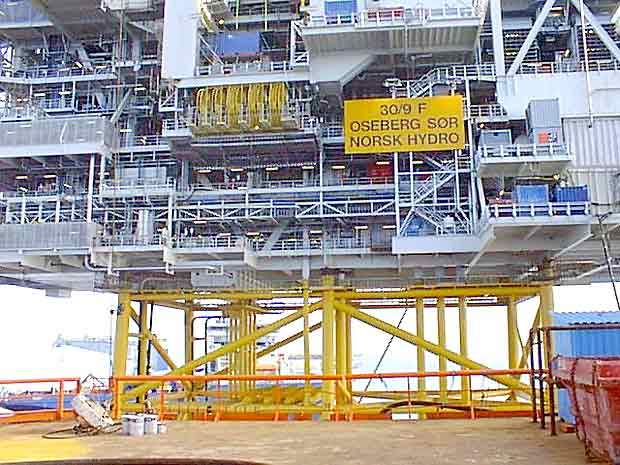

The Oseberg Sør field was discovered in 1984, when Norsk Hydro drilled well 30/9-3.

The field is located 115km from the shore and 13km from the Oseberg field in a water depth of 101m.

The field was originally operated by Norsk Hydro, with a 32.02% interest, on behalf of Statoil, Conoco and Mobil.

However, Norsk Hydro and Statoil agreed to merge in December 2006 as part of a £15bn deal, which at the time created the world’s biggest offshore petroleum operators.

Oseberg Sør includes several small structures, notably Omega G, B, J, C, K and X, which all lie in the south of the main Oseberg field.

The accumulation lies in block 30/9, across production licence numbers 079, 104 and 171, which were awarded in 1982, 1985 and 1991 respectively.

The project was given development consent in June 1977. The Visund and Troll fields in the North Sea are also part of the Oseberg Sør field.

Oseberg upgrade

Aker Solutions was awarded a Nkr1.3bn engineering, procurement, construction and installation (EPCI) contract by Statoil in March 2009 to upgrade existing drilling facilities on the Oseberg B platform, one of the four platforms at the field.

The upgrade project will increase the productivity lifespan of Oseberg B.

Aker Solutions will provide prefabrication and offshore equipment installation. The upgrade project is expected to be complete by April 2013.

Statoil has also taken up a modernisation programme at the Oseberg field to decrease the intake pressure for oil coming into the centre of the field.

The modernisation includes installing low-pressure flow pipes and new low-pressure manifolds on Oseberg B.

It also includes the installation of pipes from the low–pressure manifolds on Oseberg B over the bridge to Oseberg A, where the pipes will be connected to the Oseberg A second-phase separators.

In addition, gas compressors and production trains will be upgraded by Greenland Group to support the low production pressure.

The low production pressure increases the oil recoveries up to three or 4 million cubic metres, corresponding to 20 million to 25 million barrels.

Two separators have been installed in the Oseberg field. The first-phase separators have a pressure of 67bar and comprises oil and gas on oseberg A.

The modernisation of the Oseberg field enables the oil to go directly in to second-phase separators having a pressure of 20bar.

Subsea system

FMC Technologies has been awarded a Nkr38m contract by Grenland Group in March 2009 for constructing Troll B Gas Injection Subsea Structures.

The contract work encompasses fabrication of two integrated satellite structures and two Flow Modules for Statoil’s Troll B gas injection project.

The gas injection structures will increase the Troll’s oil reserves by 17 million barrels.

A Nkr330m contract was also awarded to Aker Solutions by Statoil in March 2009 for delivering complete work-over system for subsea trees at Kristin field.

The field in the Norwegian Sea has high-pressure / high-temperature subsea tress. The work-over systems will increase the production in the subsea wells.

Aker Solutions will provide engineering, procurement and manufacturing services. It will also test work-over intervention system.

The work-over system being installed is the third and can operate at temperatures and pressures up to 180°C and 15,000psi respectively.

The third work-over system was delivered to Statoil in March 2009. The overall deliveries are expected to be completed by May 2010.

Contracts

In September 2007, Grenland Group was awarded a Nkr625m contract by Norsk Hydro to modernise the Oseberg Field Centre to operate at a lower production pressure.

Further, a Nkr300m contract was awarded to Aker Solutions by Statoil in October 2009 for supplying subsea equipment to its Visund and Troll fields in the North Sea, comprising subsea tree number 100 for Troll.

The work in the contract encompasses six subsea trees with control systems for the Visund field and three subsea trees with controls for the Troll field.

Around 27 subsea trees were delivered to Visund and Visund North up to October 2009, which were equipped with Aker Solutions’ most advanced subsea technology.

Each subsea equipped with its latest technology has a life span of one year.

The contract forms part of five-year frame agreement signed between Statoil and Aker Solutions in August 2007 for providing subsea production systems and related operational services.

The deliveries will be completed in first quarter of 2011.

Platforms

The Oseberg field centre comprises four platforms, namely Oseberg A, Oseberg B, Oseberg C and Oseberg D.

A concrete base platform Oseberg A comprises process equipment and living quarters, while Oseberg B has drilling, production and injection equipment.

A drilling accommodation and production platform Oseberg C is equipped with a steel jacket, while the Oseberg D is a steel platform fitted with gas processing and export equipment.

The resorvoir pressure was fallen by 70bar to 100bar since its inception in December 1988.

Around ten wells will be modified into second-phase separators. A low-pressure resorvoir production will be commissioned in 2009 with completion in 2010.

Reservoir

The depth to the oil / water contact ranges from 2,300m to 3,100m and the maximum sand thickness / oil column is 150m-200m.

The reservoir measures 18km x 15km, it has a porosity of 18%-22% and its permeability ranges from 10mD-3,000mD.

Its oil density is 31.1API-39.4API and the oil viscosity is 1.36cp-1.75cp. The draining strategy is based on pressure, maintained using water-injection or water-alternating gas.

The recovery factor varies from structure to structure, from 16% to 44% with an average of 34%.

Recoverable reserves have been estimated at 53.3 million cubic metres of oil and 11.4 billion cubic metres of gas.

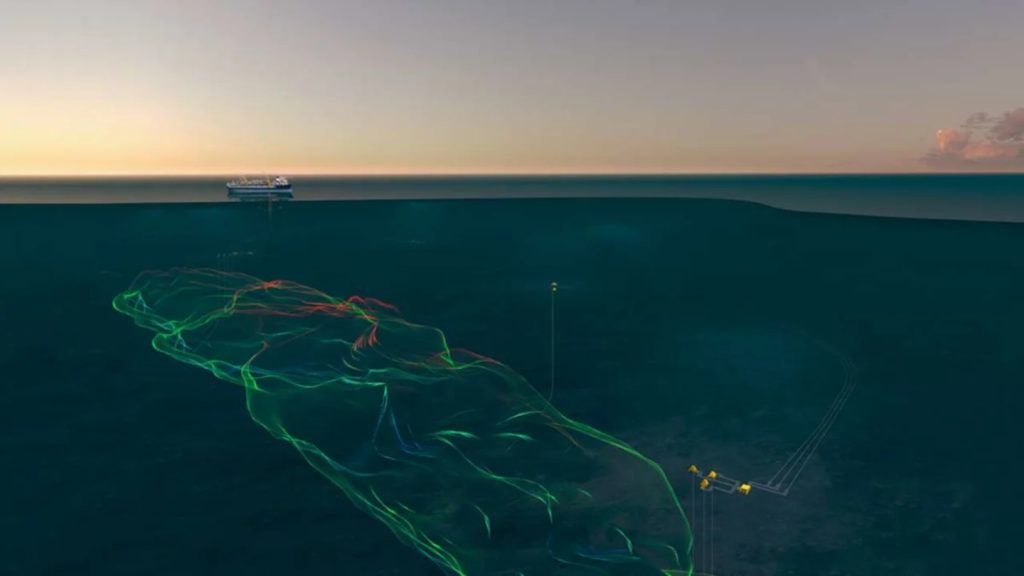

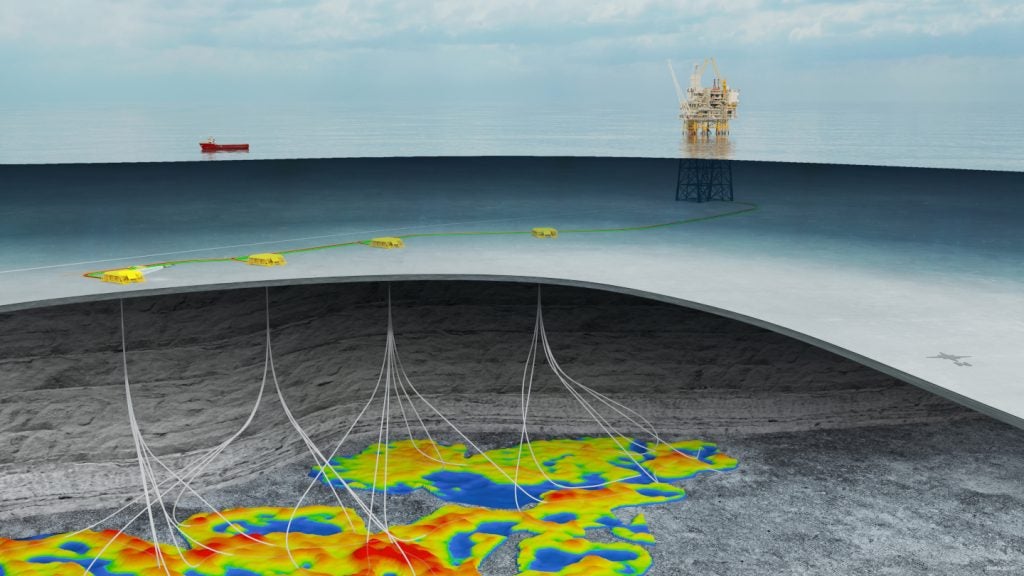

Most of the Oseberg Sør wells are drilled from facilities on the Oseberg Sør platform, however, there are also two outlying structures.

These were installed in early 2000 and will be tied in to the installation using infield pipelines.

The well plan encompasses 30 wells in the main reservoir, as well as another three in the Usira structure.

These break down into 16 production wells, 14 injection wells and three water-production wells.

The main reserves lie in the Brent Group (Middle Jurassic section), but discoveries have also been made in the Heather and Draupne formations (Upper Jurassic).

Ten potential reservoir structures lie within the area and seven of these were incorporated into the basic operations plan.

Before Norsk Hydro came to the region the profitability of the site was in doubt, but the field’s estimated resources have increased by almost 50 million barrels of oil in place, of including 15 million barrels of recoverable oil.

Part of the Omega Nord structure can be reached from the Oseberg field centre and can be produced and metered from there.

The development concept for Oseberg Sør is an installation with living quarters, a drilling module and the partial processing with a first-stage separation of oil and gas.

It is supported by a lattice steel-jacket substructure. The platform deck has been built as an integrated structure, as far as the offshore lifting capacity allows.

The platform has design production capacities of 4,900m³ per day of oil and 13,000m³ per day of water, with the fiscal metering of the oil.

It is also designed to accommodate gas production of 3.8 million cubic metres per day, to carry out water injection at 41,500m³ per day and gas injection at 38 million cubic metres per day.

Partly stabilised oil will be transported in a 12in pipeline for further processing at the Oseberg field centre and export through the Oseberg Transportation System to Sture.

Associated gas will be injected into the Oseberg Sør reservoir.

Fabrication

The fabrication was carried out under an engineering, procurement and construction contract for the topsides and jacket, as well as the offshore hook-up.

The topsides were fabricated by Aker Stord in a Nkr2.7bn contract. The 13,200t topsides include an accommodation module that can house 100 people.

The drill package is 20% smaller than a standard unit. It is designed to operate over a 32-slot well pattern. This consists of a skid-base assembly, a substructure with four main levels and a drilling rig.

Horizontal and vertical pipe handling is remotely controlled from an enclosed drilling control room, using three 20in monitors.

The 124m-tall steel jacket, costing around Nkr300m, was fabricated in the Aker Verdal yard.

Fabrication of the Troll B gas injection subsea structures by FMC Technologies will be completed by the first quarter of 2010.