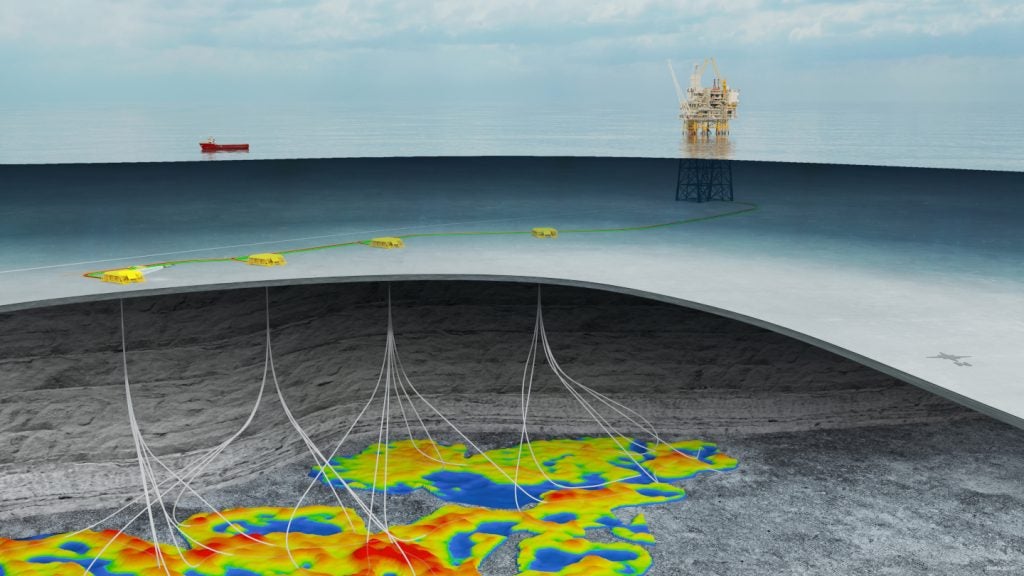

The Sable Offshore Energy Project lies near Sable Island, 10km to 40km north of the edge of the Scotian Shelf, offshore Nova Scotia, in water depths ranging between 20m and 80m. The Sable Offshore Energy Project consists of the six gas fields Venture, South Venture, Thebaud, North Triumph, Glenelg and Alma. These contain about 85 billion cubic metres of recoverable gas reserves. The Sable Project is projected to last until the year 2025.

An estimated 28 production wells are anticipated for the project. The first 12 wells, planned to be drilled at the Thebaud, Venture and North Triumph fields, were completed by the end of 1999.

The drilling programme was shared between Rowan and Santa Fe (Canada). The Rowan Gorilla II and the Santa Fe Galaxy II will be used. Previous drilling in the area has indicated the presence of high-temperature, high-pressure wells.

The fields are being developed in two stages.

The first phase of the Sable Island project saw the development of the Thebaud, Venture and North Triumph fields in November 1999.

Thebaud

Thebaud is used as the gas-gathering hub. North Triumph and Venture have been developed as satellite platforms, feeding into Thebaud.

The central Thebaud complex consists of two bridge-linked platforms. The larger platform has accommodation for approximately 40 offshore production workers and support personnel. The second and smaller of the two platforms supports the wellhead and processing equipment and collects and dehydrates gas from all of the fields in production.

North triumph and venture

These will be developed by unmanned satellite platforms although they will be occupied as field operations require. The platforms will incorporate dry wellhead structures and minimal processing facilities to separate produced water from the gas and natural gas liquids.

Contracts: topsides

The Thebaud topsides facilities were fabricated by Kvaerner Oil and Gas at its Teesside facilities in a $65 million contract. The North Triumph topsides fabrication contract was won by a joint venture between MM Industra and Brown & Root. The contract’s estimated value is about $13 million with about 90% of the 100% Canadian content coming from Nova Scotia.

The Dartmouth-based Fabco / CKT joint venture (JV) won the $16.7 million fabrication subcontract for the Thebaud and Venture accommodation modules.

Contracts: jackets

The $13 million contract for the construction of the Thebaud and Venture jackets was awarded in April 1997 to the joint venture between MM Industra and Brown & Root. The scope of work included the procurement, construction, construction engineering, fabrication, loadout and seafastening of the two jackets and piles.

The two remaining (Thebaud accommodation platform and North Triumph) jackets were fabricated by Texas-based Peter Kiewit Inc in its Corpus Christi yard.

Sable island installations

The steel wellhead jackets were installed on Thebaud and Venture at the start of the project and then a jack-up was used to pre-drill the wells over them. The jackets were installed in April 1998 by the crane vessel M7000.

Pipelines

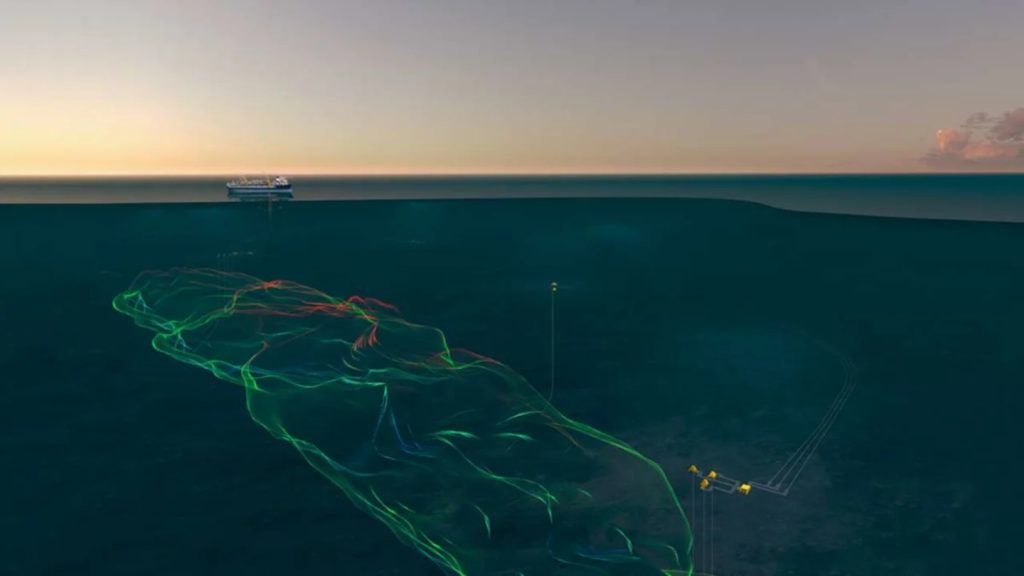

Infield lines ranging from 5km to 55km, with an outside diameter of up to 457mm, are used to link the platforms with the Thebaud gas gathering hub. In all there will be around 175km of interfield pipelines to be installed.

The gas and natural gas liquids from Sable Island are then transported through a two-phase subsea pipeline from Thebaud to the onshore facilities in the Country Harbour area. The pipeline will be 225km-long, with an outside diameter of 609mm. The pipeline corridor was chosen to avoid significant fishing areas and other sensitive sites.

The $250 million pipelaying was carried out by Allseas in August 1999, using its giant pipelaying ship Solitaire.

Halifax-based Shaw and Shaw was awarded a contract for the anti-corrosion and concrete weight coating of subsea interfield flowlines across the Sable Island field and the main gathering line.