How Nanobubbles Can Increase Recovery and Improve Efficiency

Nanobubbles have distinct properties related to their small size that make them helpful for a wide range of industrial applications.

AquaB is revolutionising the productivity of liquids by bringing low-energy, electrostriction nanobubble technology to the market.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

AquaB is revolutionising the productivity of liquids by bringing low-energy, electrostriction nanobubble technology to the market.

For the oil and gas sector, nanobubble technology delivers transformative efficiency and productivity gains, most notably in the following processes:

AquaB’s patented generators produce high concentrations of bulk nanobubbles at scale with minimal energy needs. This new approach to generation – using electric fields rather than high pressure and membranes – enables process control, solid-state reliability and deployment flexibility.

Nanobubbles are proven to amplify the functional performance of liquids in physical, chemical and biological processes by, for example:

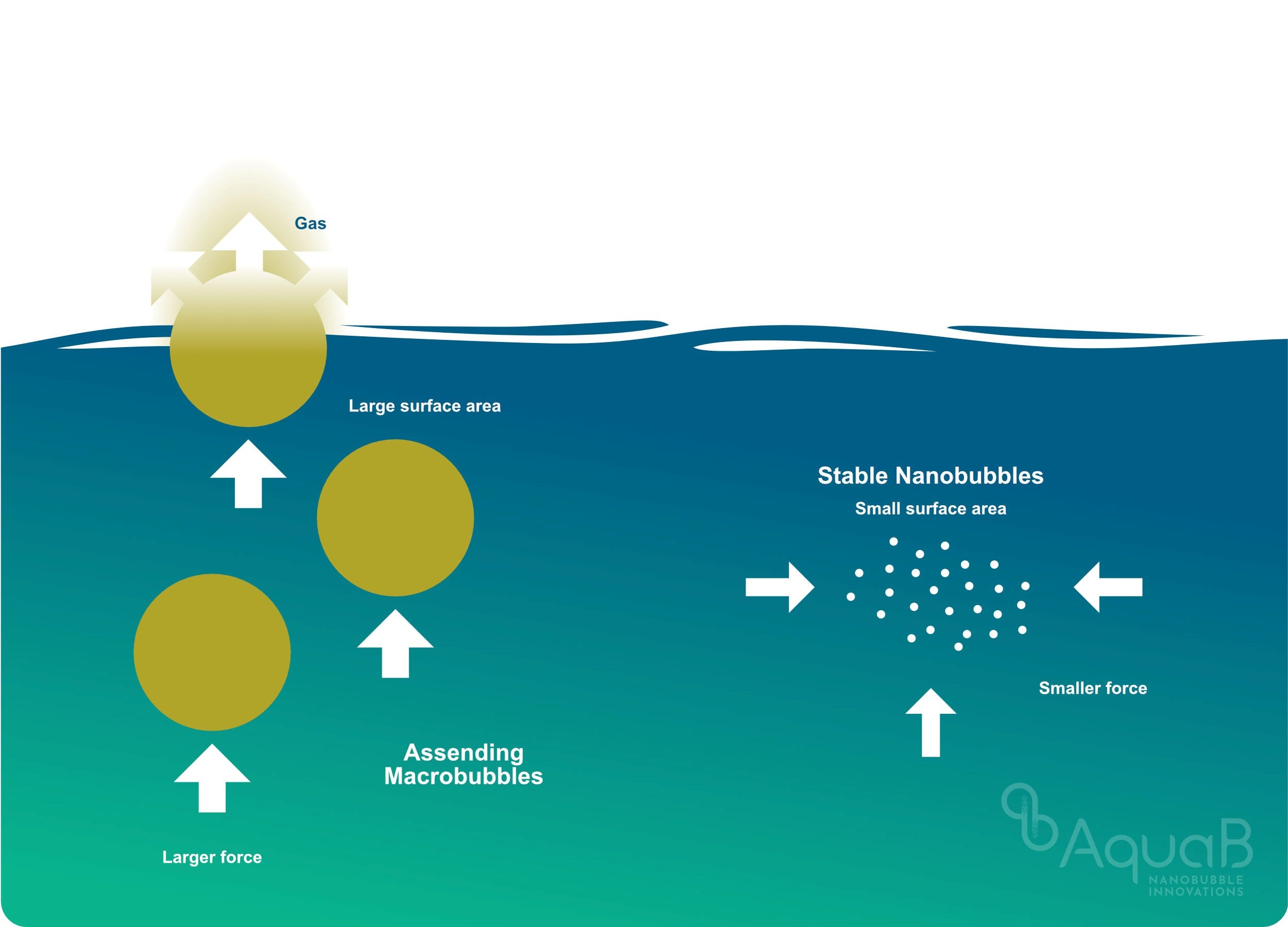

The smaller a bubble, the less buoyant it is and the larger its relative surface area. As the smallest, ultrafine bubble, nanobubbles have distinct properties including high stability and an extended lifespan. The industrial potential of nanobubbles has been known for years, but the barrier to widespread use has been the challenge of developing energy-efficient, controllable, reliable generation.

AquaB’s patented electrostriction technology solves those barriers head-on. Field trials also suggest that AquaB’s unique electrostriction technology confers additional advantages over industry standards, including a significantly extended lifespan.

We have identified oil and gas as a priority industry for AquaB and will begin the widespread roll-out of our turnkey nanobubble generators in early 2024. Some advance availability of our in-line pipe-based generator is anticipated.

This model generates nanobubble levels of 108 per ml in a 100l/min unit, with nanobubble lifetimes lasting multiple days and even weeks.

Unlike existing technologies that use high-pressure, membranes and gas to generate nanobubbles, AquaB generators use an electric field. This gives our generators market-leading advantages, including:

Aqua-B’s technology is based on electrostriction phenomena, induced by the application of electric fields.

Our patented technology is solid-state with few moving parts, resulting in very little maintenance or downtime because there’s nothing to get blocked or jammed, which means early adopters of AquaB technology are enjoying significantly reduced downtime.

Our generators can also be powered by solar in off-grid, in-field environments, with no need for added chemicals or gas, which makes them highly flexible and adaptable.

In both on- and off-shore water treatment operations in the gas and oil sectors, activated-sludge approaches are necessary for biological treatment operations as an alternative to flotation operations.

Here, AquaB can offer massively increased and low-energy nano-oxygenation, together with high-performance abiotic oxidation of reactive nitrogen and sulphur species, reduction in COD and BOD, as well as improved micro-biology profiles.

Nanobubble-enhanced floating sludge is more uniform and smaller in size than in conventional DAF systems, providing a better consistency for pumping, increased sludge density and lower water content in the floating sludge.

Nanobubbles give PFAS removal processes a head start at a molecular level by raising impurities to the top of a solution, where they can be mechanically removed.

The same enhanced-flotation principle applies to other impurities and micro-particulates, with nanobubbles doing the ‘heavy lifting’ before more refined downstream removal techniques are deployed, such as membranes.

Nanobubbles have a low rising velocity, which extends the life of the bubble. This, combined with the ‘ultra-dense’ nature of AquaB’s nanobubble generation, leads to more efficient removal of particles from solutions, with the nanobubbles helping contaminating particles to connect to, and collide with, larger microbubbles to facilitate flotation.

Operational efficiency and energy consumption are two industry challenges that AquaB’s nanobubble technology addresses. AquaB generators can be retrofitted to existing DAFs with ease, with either submersible or continuous-mode flow operation, which can increase the capacity of any footprint-constrained plant.

Nanobubble technology can increase oil recovery efficacy and decrease costs by shifting the thermodynamic goalposts of mature oil wells, and it can increase the effectiveness of oil recovery systems. It does this by harnessing flotation. Nanobubbles stick to oil droplets, creating aerated oily flocs that increase the efficiency of flotation-based oil-separation operations. Effectively, this allows oil to be recovered more easily.

AquaB’s nanobubble technology has been shown to boost the thermodynamic efficiency of the combustion of calorific fuels via nano-gasification and emulsification. This has exciting potential for engine and propulsion efficiency in the offshore oil and gas industry.

AquaB’s electrostriction technology means that for the first time, nanobubbles can be bulk generated using ultra-low energy input at ambient temperature and pressure and, in the case of air, direct from the atmosphere.

The bubbles produced by AquaB generators are the smallest in the industry, less than 50–100 nm in size, with industry-leading lifetimes. This means the impact of the nanobubbles is amplified. Even better, AquaB generators can be retrofitted to integrate with existing systems, making them easy and affordable to deploy and scale up.

Nanobubbles have distinct properties related to their small size that make them helpful for a wide range of industrial applications.

Nanobubbles are tiny bubbles that deliver massive impact.

Deploying nanobubble generator technology as part of Enhanced Oil Recovery (EOR) operations can lead to efficiency gains and increased recovery of up to 5%, according to a white paper published today by AquaB Nanobubble Innovations.

A major and fundamental challenge in water treatment is the limited solubility of gases in water.

People working in the oil and gas sector are being invited to learn about the potential of nanobubbles to amplify the productivity of a range of industrial processes, with the launch of a new self-led audio course on nanobubbles called 'Nanobubbles 101'.