High-Flow High-Pressure Pump

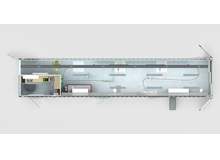

Resato’s mobile BMS pump system enables users to test objects on different locations within a workshop, allowing for high-quality testing on different sites.

Through its wheels (or forklift pockets) the BMS can in comparison to a workshop unit more easily be moved, which gives you the opportunity to be flexible in the layout of your workshop.

Furthermore, the pump system is an ideal pump to adapt to your specific requirements for testing large volumes at high pressure.

The BMS is often equipped with two air driven pumps. Hence, if you want to speed up your operation process by testing objects more quickly, a high-flow, low-pressure air-driven pump can be added to the high-flow high-pressure pump that is standard part of the BMS.

- Mobile pressure unit

- Robust design

- Suitable for pressurising with oil, water or an emulsion of both

- Modular design with numerous options

Operation

Like most of Resato’s systems, the BMS operates through pressurising, isolating pressure and bleeding.

With the BMS you can optionally keep control of and adjust the output pressure by installing a gauge and / or a chart recorder.

As a result, the bleeding process can be adapted to the preferred course of the bleeding process.

Once the desired output pressure is reached the Resato air driven pump will automatically stop, which will save energy and reduce the noise level on the working site.

Another advantage of the air-driven pump is its ability to adjust the pressurising in building up and controlling pressure.