Spirax Sarco

Steam Systems for the Oil and Gas Industry

Spirax Sarco offers a wide range of steam system solutions and services for the offshore industry.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Spirax Sarco offers a wide range of steam system solutions and services for the offshore industry.

We provide you with the support you need in designing, engineering, procuring, fabricating and testing to improve and sustain your plant’s efficiency.

Spirax Sacro can support clients from the front-end engineering (FEED) phase to installation and commissioning. Our network of engineers and support staff are well-versed in the requirements of the oil and gas industry and are here to help you in the design of your steam systems.

We have an extensive and high-quality product range with the necessary product and manufacturing approvals and bespoke documentation, including traceability. With manufacturing capabilities strategically located in the UK and around the world, we have the supply capacity and agility to suit your needs, including product packaging and local support where necessary.

Steam and condensate audits, studies and service agreements for oil and gas

Spirax Sacro benchmarks your system and identifies improvements through:

- Steam trap and leak surveys

- Heat tracing optimisation

- Engineering reviews

- Optimisation studies and audits

- Solutions development and FEED

Our reports explaining our recommendations will help you meet targets, improve reliability and safety, meet the estimated cost of implementation, as well as the potential return on your investment. We can then work with you to deliver the recommendations identified on time and within budget.

Having invested in your steam system by bringing it up to its optimal operating efficiency, it makes economic sense to maintain it at that level. Our large team of field-based service, commissioning and survey engineers will help you to put together a service agreement that keeps your maintenance requirements within your budget.

Steam system solutions and parts

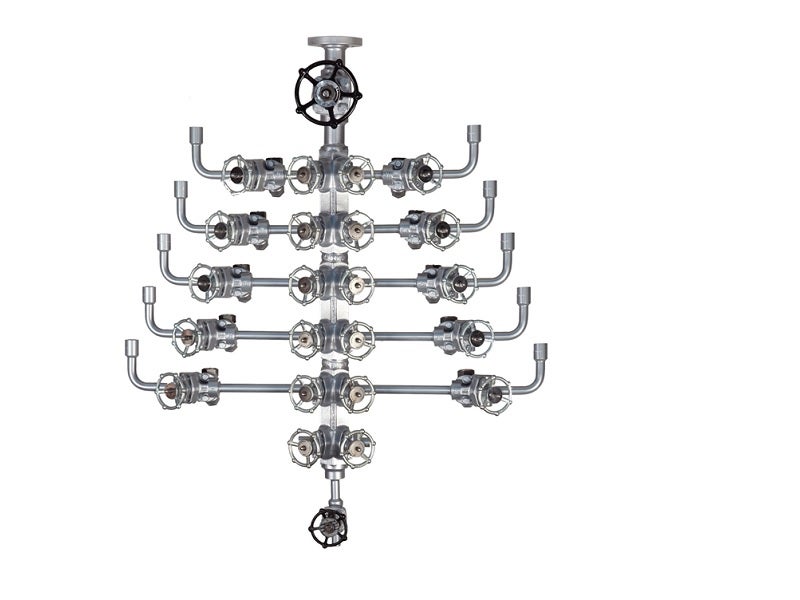

Spirax Sarco’s wide range of steam system components will keep operations running as efficiently as possible, delivering steam of the right quality and condition to your processes. Designed for quick and easy maintenance and long life, our products will help minimise breakdowns and optimise productivity.

We can be your single supplier for all steam system requirements, from condensate management and return, steam trapping equipment, controls and instrumentation to bespoke packages. We offer quick and reliable supply, as well as support in selecting the most suitable solutions for your application.

To ensure we consistently reach the high levels of product quality you require, we manufacture to ISO 9001 and ISO 14001 certified quality management systems. We are also experienced in complying with global oil and gas requirements, offering a range of product testing and inspection options along with full traceability of raw materials.

Certification and documentation

Spirax Sarco offers Certificates of Conformity 2.1 and typical testing reports where applicable are available. These include hydraulic tests, steam tests and air tests.

We also provide inspection certificates such as 1 material ISO 10474/EN 10204, ASME and API.

Document control system and final quality dossier packages

Our dedicated team can provide you with comprehensive oil and gas project documentation that complies with all legislation and market requirements. We understand the need for this documentation to be completed promptly and with full traceability and certification and so we use our ISO 9001 accredited Order Management Portal. This online quality management system efficiently manages all documentation to ensure all deadlines are met, and that projects run on time.

We provide fully customisable, project-specific documentation packages that include:

- Drawings

- ITP/Quality Control plan

- Procedures (welding, non-destructive examination (NDE), painting, packing, hydro-test)

- Reports & test certificates (welding, non-person entity (NPE), painting)

- 1 material certificates

- Installation and operation manuals

- Spare parts list

Contact Details

Website

Email Address

Address

15 Cirencester Road,

Cheltenham,

GL53 8ER,

England