Deep Trekker

Underwater ROVs for Offshore Infrastructure Inspections

Deep Trekker manufactures remotely operated underwater vehicles (ROVs) for exploration of oceans, seas, lakes and rivers.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Deep Trekker manufactures remotely operated underwater vehicles (ROVs) for exploration of oceans, seas, lakes and rivers. In addition to providing equipment, the company works closely with clients, sharing its expertise and supporting developments in the offshore energy industry.

Underwater inspection of offshore infrastructure

With the global population growing, efficient production and delivery of energy is becoming increasingly important. Many of the new developments in the energy industry involve underwater infrastructure, which needs to be monitored to ensure efficiency and safety, as well as assess environmental impact and carry out inspections for maintenance issues. Deep Trekker’s mini ROV systems can be used in conjunction with divers or used independently in order to carry out routine inspections or emergency work.

Deep Trekker portable ROV systems have been used to inspect installations for sea-based wind and solar operations. The company has refined its tools for use in oil and energy-related industries, including creating one-man carry ROV systems that can be operated from a boat.

Remotely operated underwater vehicles (ROVS) for the offshore industry

Reaching depths of 200m, the DTG3 is designed to last longer with an eight-hour battery life. Its enhanced viewing and recording ability provides smarter inspections with its live, 4K video and waterproof handheld controller.

Powered by BRIDGE technology, the DTG3 provides advanced stability even in adverse underwater environments, as well as the freedom to move with direct sonar integration and an automated station holding capable of rotating 270 degrees.

The Deep Trekker REVOLUTION is engineered to be robust and is made from carbon fibre and stainless steel. It features auto-stabilisation, augmented recording capabilities, wireless connectively and 4K ultra HD video resolution.

The ROV is based on an automated station holding, allowing the camera, sonar and manipulator arm to rotate 260 degrees for advanced situational awareness and flexibility. It can be remotely controlled to depths of 305m underwater. The vehicle’s manipulator arm has a close strength of 70lbs and the ROV tether can pull up to 300lbs to the surface.

Deep Trekker REVOLUTION is designed to detect and locate objects hidden beneath the water, as well as assist divers to safely conduct underwater inspections in harsh environments. Partnered with BRIDGE, Deep Trekker REVOLUTION provides improved stability in underwater environments.

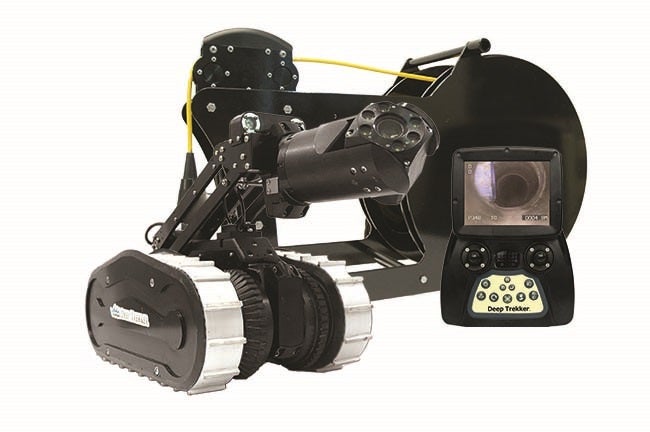

Pipe crawlers for offshore applications

Made from anodised die-cast aluminium and stainless steel, as well as featuring a sapphire glass camera lens cover, the DT340 pipe Crawler is designed for tough environments.

A magnetically coupled drive requires no maintenance and is inherently waterproof, meaning that there are no dynamic seals on the DT340 that need to be greased or replaced. The optional tracks system is manufactured from steel cord reinforced polyurethane, so it can manoeuvre over any encountered obstacles.

As no power is sent through a tether, inspections are safer and aerodynamics are improved as the crawlers pull weight is reduced. Though the DT340 tether may be thin, it is reinforced with synthetic fibres for extra strength.

The DT320 Mini Pipe Crawler is designed with for optimal portability, allowing operators to conduct storm and wastewater inspections without the need for topside power.

Complete in one compact carrying case, the out of the box system in deployable without generators or power supply onsite. With an easy to use controller, it is the only battery-operated CCTV pipe crawler of its kind.

The DT320 Mini Crawler is easy to operate with the use of its handheld control console. Visual catalogues of inspections can be created and integrated directly with asset-management software. It can also be equipped with various wheel options and tracks so the camera can be tailored for the project.

Submersible utility crawlers for oil and gas projects

The DT640 Utility Crawler is a three-wheel submersible, which comes with a magnetic wheel option to allow for various inspection works.

Compact for transportation and portability, the DT640 can be deployed from any location. It is an optimised system for remote inspections with optional customisation, including pressure washing, vacuuming and thickness testing.

The DT640 MAG provides a safe and efficient alternative to ship hull and steel structure inspections. Its on-board HD camera and live-video feed provide operators with instant visual inspections in remote environments. Its unique design allows it to latch onto the side of large ships and vessels, as well as perform visual inspections, even while in transit.