Metas provides subsea technology and services focused on asset integrity monitoring within the global oil and gas sector to improve safety and response time to incidents. The company also verifies the integrity of subsea systems throughout the lifecycle of the field, from drilling to abandonment.

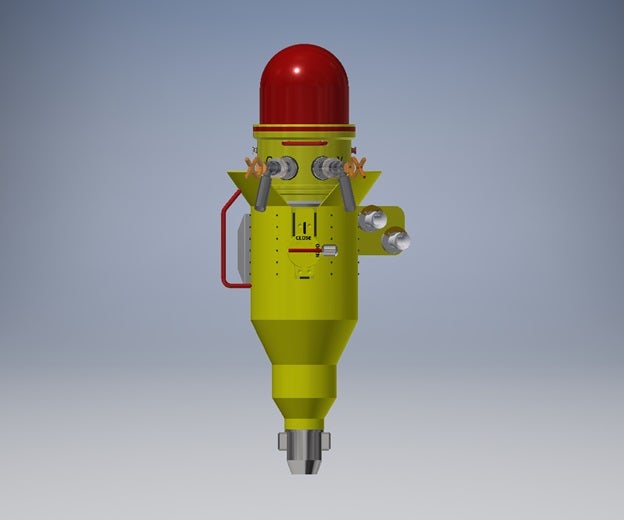

Subsea hydrocarbon and CO2 Wide Area Active Monitoring (WAAM) systems

Metas is committed to making subsea operations as safe and cost-effective as possible by actively monitoring infrastructure and giving early warnings of any hydrocarbon or CO2 leakage. The monitoring systems will identify, alarm and measure leakage rate down to 10g per minute, as well as report the location of a leakage source within the system. The intelligent software maps the monitored area and avoids false alarms from natural seeps, wildlife or other disturbances.

Monitoring systems can be supplied in two distinct versions, a cabled system with direct communications or a battery powered solution with acoustic modems.

Leak detection systems monitor a large area, continuously scanning a 1,000m radius from installation, up to 360° around, resulting in an area of 3.14km² (1.2 square miles) per unit. The system can monitor the water column from the seafloor, indicating the volume discharged and the flow path for tracking and mitigation actions.

Subsea asset integrity monitoring

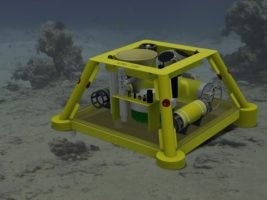

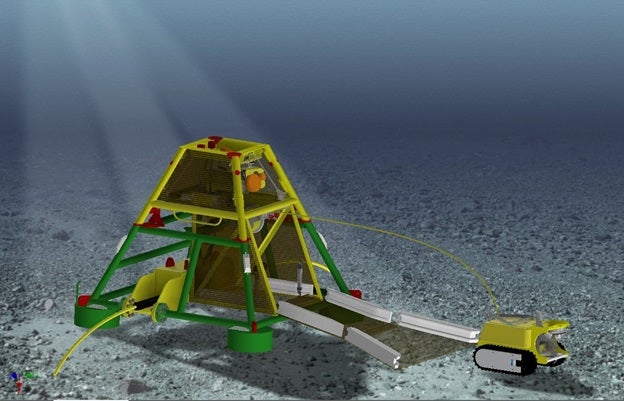

Through a partnership with iSeaMC, Metas can integrate a robotic ROV or AUV with the subsea monitoring stations. The robot design is field-proven with more than ten years of operation in the deepsea.

The robotic design is in the form of a crawler or rover with a range of instruments, lights, camera and manipulator as needed for the mission. It can be controlled remotely live or through pre-programmed operations to travel across the seafloor to monitor the surrounding environment and infrastructure.

The ROV/AUV can be used to monitor the environment for changes, or it can be tasked to investigate a potential leakage site for real-time images and inspection with sophisticated scientific instruments. The crawler can also carry out small tasks, such as operate valves, as long as they are within reach of the manipulator arm.

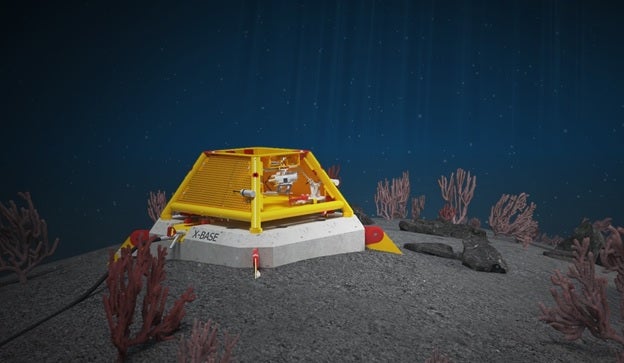

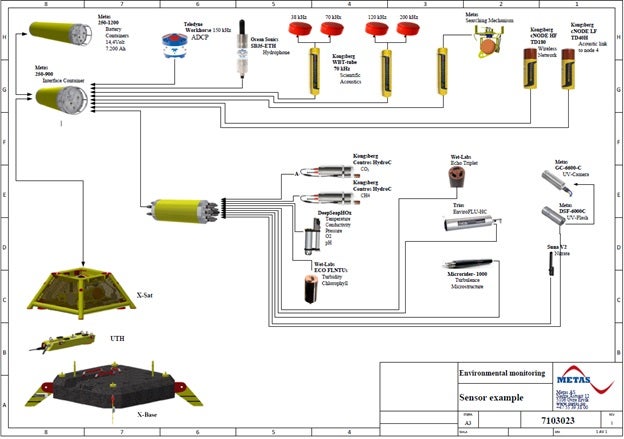

Subsea environmental monitoring stations

Metas has developed subsea environmental monitoring stations in collaboration with oil and gas operators and marine research institutes to meet the reliability necessary for long-term deployment (25 years), regardless of the mission. The systems have been in operation on the seabed since 2011, conducting research and assisting oil and gas operators in protecting the marine environment.

With standardised and modular instrumentation deployment systems and an ROV-free landing and recovery tool (LRT), Metas can rapidly configure a project specific monitoring system and deploy it from a wide array of vessels.

In addition to active acoustic systems, environmental monitoring stations can support all standard subsea scientific instruments, as well as a local crawler robot for direct observations at a distance from the station.

Systems are available to rent for short-term (less than six months) surveys or scientific research.

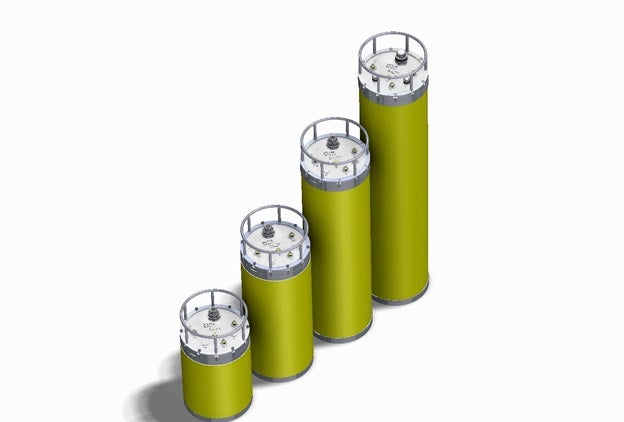

Subsea battery containers, cameras and hydrophones

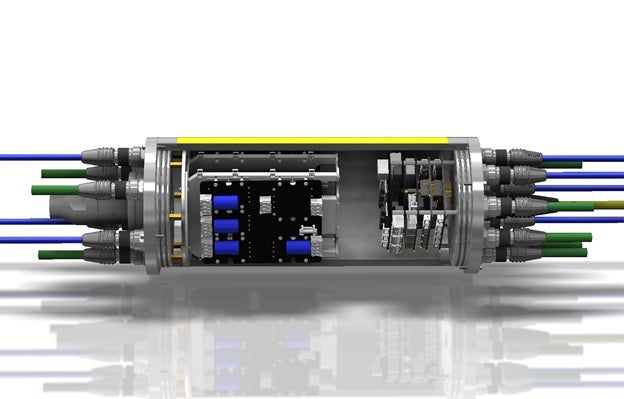

Metas has designed and developed key components to ensure the reliability of its systems and make them available to other companies within the subsea industry.

Notable examples include subsea battery containers featuring all metallic components in titanium to avoid corrosion issues, mated with strong carbon-fibre sleeves to ensure strength with the lowest weight possible.

Metas’s Subsea Interface Units provide a standardised solution to interface the full range of subsea drives and instrumentation with the needed power distribution. As with the battery containers, all metallic components are titanium and the main housing is carbon-fibre.

In order to connect the various instruments with the battery container and interface unit, Metas has developed a line of high integrity subsea dry-mate connectors in both bulkhead and cabled versions. All wetted metallic components are titanium to ensure reliability.

Subsea Cameras are key components for many inspection and research projects, and Metas has developed a series of subsea housing for a range of camera types from low light video to stereoscopic high-definition.

Hydrophones are also a common component in many environmental monitoring systems. Metas is the distributor of Ocean Sonics Hydrophone systems in Norway.