DEMAnor originally specialised in cranes and material handling solutions in cooperation with DEMAG. The company has since expanded to offer umbilical and cable carousel solutions.

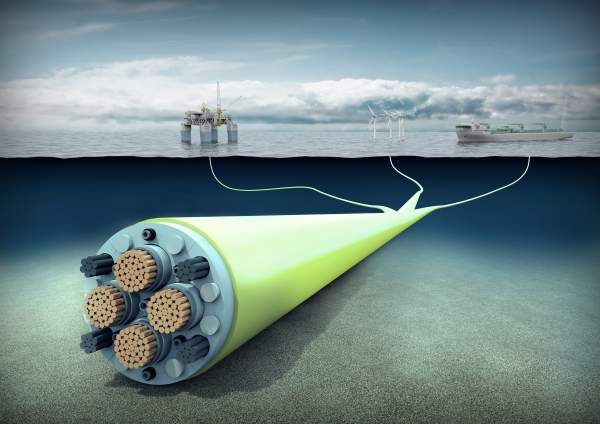

Umbilical and cable carousels

The DEMAnor cable carousels are suitable for the manufacture of umbilical, power cables, subsea power cables and other subsea cables. All drive components are standard, high-quality DEMAG components.

The company’s customised umbilical carousels are supplied in diameters of up to 50m and can handle loads of up to 4,200t. The carousel base can be divided in several compartments if required.

DEMAnor’s customised cable carousels are designed for loads of up to 12,000t, and bigger capacities and dimensions are available, depending on the client’s requirements.

Laying arms

In addition to different types of cable carousels, DEMAnor supplies hydraulic-operated laying arms, which guide cables down to the carousel. The laying arms are provided with caterpillars to feed the cable during the laying or unloading processes to and from the carousel.

DEMAnor also supplies additional necessary equipment to complete the carousel system such as outdoor operator cabins, extra caterpillars and roller paths for cabling.

DEMAnor’s carousels are equipped with traditional contactor control or a programmable logic controller (PLC). If required, the system will communicate with other PLC systems in the factory.

Customised control systems and operator cabins

DEMAnor’s operator cabins are situated ‘onshore’ of the carousel, and all control signals are hardwired or radio controlled between the control cabinet and the drive. The control system usually is placed on the carousel, while power supply and control signals are hardwired via bus bar lines.

DEMAnor’s control systems are customised according to the customer’s specifications and requirements. The company also supervises all development, engineering and manufacturing of control systems in-house.

The company works closely with its customers to make sure they have the exact solution to suit their manufacturing needs.

About DEMAnor

For more than 60 years, DEMAnor has built its reputation as a leading manufacturer in the material handling industry. Today, the company has a wide range of products that covers everything from small operations to fully automatic, heavy-duty manufacturing processes.

Based in Drammen, Norway, DEMAnor’s clients include industrial companies, including DUCO (Houston, Texas and Lobitho, Angola), Aker Solutions (Moss, Norway and Mobile, Alabama), Draka Norsk Kabel (now Prysmian, Drammen, Norway) and NEXANS (Halden and Rognan, Norway).