SPIR STAR® AG is a leading international manufacturer of ultra-high-pressure thermoplastic hoses with spiralised steel wire reinforcement for pressure ranges from 250bar (3,600psi) to 4,000bar (58,000psi) and inner diameters from 3mm to 32mm.

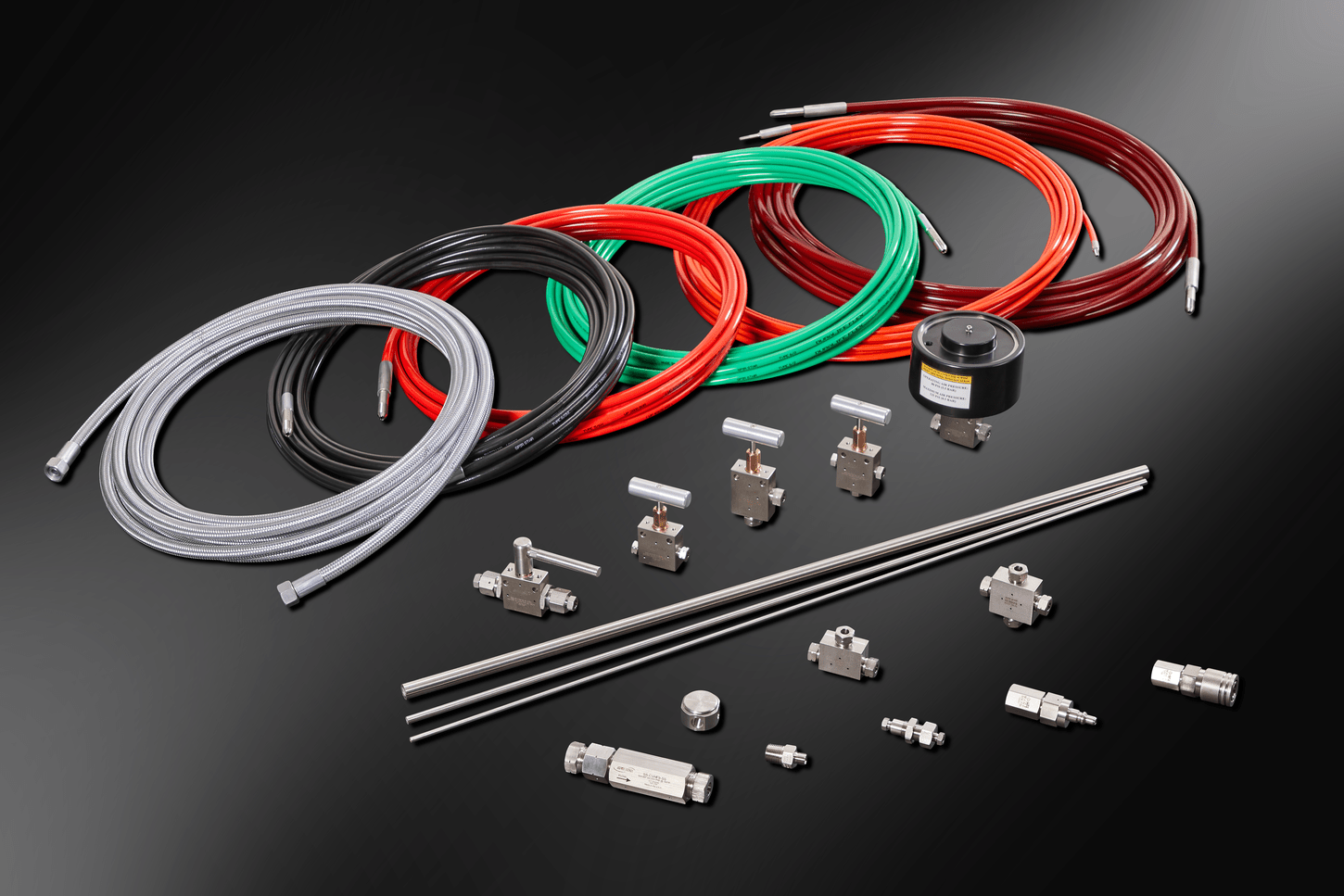

SPIR STAR® AG is expanding its product line to include high-pressure valves, adapters, tubing, and couplings that deliver impressive performance at pressures of up to 4,140bar (60,000psi).

Since its establishment in 1989, SPIR STAR® AG has become one of the world’s leading manufacturers of ultra-high-pressure thermoplastic hoses (UHP-hoses) with spiralized steel wire reinforcement. These hoses cater to a diverse range of pressure requirements, spanning from 250bar (3,600psi) to an impressive 4,000bar (58,000psi), and are available in inner diameters ranging from 3 mm to 32 mm. SPIR STAR® AG is extending its range of products to encompass high-pressure valves, adapters, tubes, and couplings that demonstrate exceptional performance capabilities under pressures reaching up to 4,140bar (60,000psi).

High-quality high-pressure hoses made in Germany

With a commitment to delivering top-notch products and providing outstanding customer service, SPIR STAR® AG has consolidated its position as a renowned player in various industry segments, including Waterjet, Hydrogen, Hydraulics, Oil & Gas, and Automotive.

In the waterjet industry, SPIR STAR® AG’s waterjet hoses are used for surface treatment, pipe cleaning, waterjet cutting and hydro-demolition.

The hydraulic hoses are used for hydraulic applications such as bolt tensioning and torque wrenching.

The automotive industry uses PTFE hoses for their chemical resistance, particularly in applications such as coating and bonding processes.

Hydrogen hoses play an important role in the refuelling of hydrogen-powered cars and the filling of hydrogen-tube trailers.

SPIR STAR® AG oil & gas hoses serve various purposes, including bundle applications, methanol services, and chemical injections.

SPIR STAR® AG is dedicated to ensuring outstanding product quality and continually aims to exceed customer expectations. The utilisation of premium materials throughout the manufacturing process and adherence to stringent production and testing standards ensures the consistent quality of high-pressure hoses. The conformance of our hose products to industry standards results in a significant portion of our products being certified according to relevant standards.

Having obtained certification according to DIN EN ISO 9001 in 1995, SPIR STAR® AG assures comprehensive documentation of processes. The company’s established Quality Management (QM) system facilitates the traceability of all raw materials used in production at any given time.

The company’s oil and gas hoses are tested according to industry-specific standards such as ISO 13628-5. We are committed to meeting the growing global demand for higher-pressure capabilities and the increasingly stringent safety regulations of each sector.

All high-pressure hoses are extensively tested prior to delivery using the latest testing equipment, including impulse test stands, tensile strength and burst pressure testers to verify the ability of each unit to achieve optimum performance. EN 10204 test certificates can be provided for individual assemblies upon request.

In addition to an extensive range of standard hose assemblies, the company’s experienced staff are able to collaborate with customers to develop customized products to meet the client’s specific project requirements.

Ultra-high-pressure hose assemblies for offshore projects

SPIR STAR® AG is a leading provider of tailor-made high-pressure hose solutions to the oil & gas industry, covering applications such as offshore hose bundles, methanol services and chemical injections. Addressing the industry’s demand for superior quality, extended service life, and chemical resistance, SPIR STAR® AG offers specialised hose types.

The ultra-high-pressure hoses made by SPIR STAR® AG not only endure elevated working pressures but also boast minimal volumetric expansion, lightweight design, and exceptional resistance to external pressure. With the capability to manufacture hoses up to an impressive length of 4,500m, SPIR STAR® AG responds to the needs of a diverse customer base.

In addition to an extensive range of high-pressure hoses, SPIR STAR® AG complements its offerings with a wide selection of high-pressure valves, adapters, and tubing designed for the oil and gas market. Manufactured from standard stainless steel, these connectors resist various chemicals, enhancing their suitability for numerous applications.

SPIR STAR® AG’s cutting-edge hose systems have been applied by major global oil & gas companies for over 35 years. Tried and tested in diverse marine projects ranging from the North Sea to the Gulf of Mexico, these robust solutions offer versatility.

Boasting low permeation rates and excellent resistance to chemicals, detergents, and solvents, SPIR STAR® AG’s durable hose assemblies feature resilient outer covers designed to protect against external pressures, hydrolysis, and microbes. Ideal for harsh deepwater locations, these hoses exhibit low volumetric expansion even at maximum working pressure and are compatible with extreme temperatures of up to 150°C (300°F). Their robust design ensures a small bend radius at maximum flow rates, delivering consistently superior performance over long and intensive service periods.

Hydrogen hoses for car refueling and hydrogen-tube trailer filling

Since 2009, SPIR STAR® AG has also been a pioneer in providing innovative hydrogen hoses to meet the critical needs of the energy transition and mobility sectors. The hydrogen hoses are successfully used for vehicle refuelling at 350bar and 700bar. The 6mm hydrogen hose type, designed for direct car refuelling at the dispenser, is fully certified to ISO 19880-5, making it ideal for SAE J2601-compliant refuelling processes. In addition, SPIR STAR® AG offers transfer hoses with larger diameters to handle higher flow rates, suitable for applications such as hydrogen refueling of tube trailers, ships and trains.

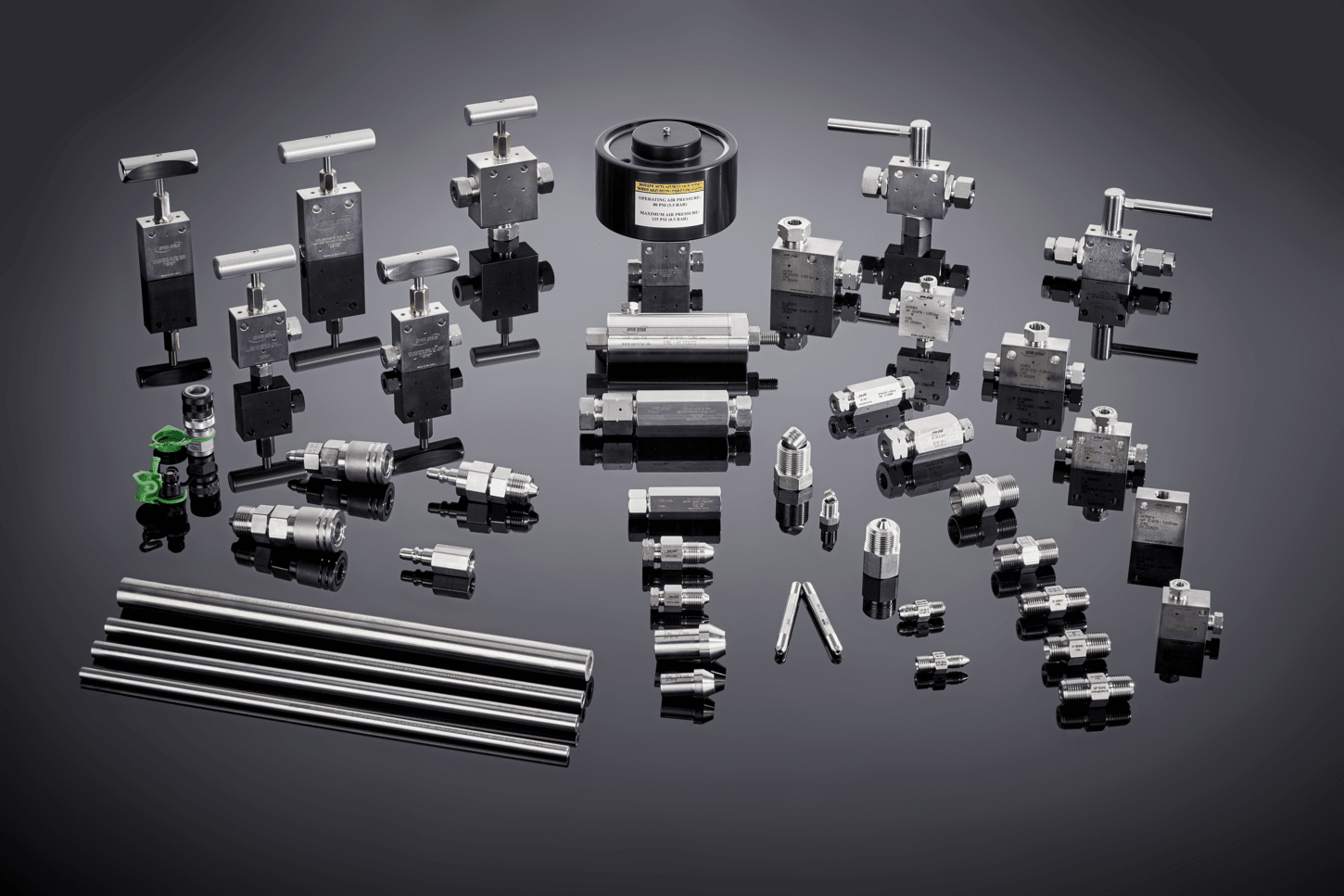

High-pressure valves, adapters, tubing and couplings

In addition to hose systems, SPIR STAR® AG provides an extensive selection of high-pressure valves, adapters, and tubing tailored to the needs of the oil & gas sector. Our standard high-pressure connectors manufactured from durable stainless steel exhibit resistance to various chemicals, making them suitable for various applications.

SPIR STAR® AG provides a wide range of valves, including high-pressure needle valves, ball valves, check valves, and pressure-relief valves, available with various thread types and a maximum working pressure of 4,140bar (60,000 psi).

Additionally, SPIR STAR® AG offers high-pressure adapters. These are available in many thread types and sizes.

SPIR STAR® AG’s high-pressure tubing, manufactured from seamlessly drawn stainless steel, ensures top-notch quality within a pressure range of up to 4,140bar (60,000psi).

For cross-industry applications, SPIR STAR® AG offers quick-release couplings with a maximum possible working pressure of 2,070bar (30,000psi), providing versatile solutions irrespective of the industry.

About SPIR STAR® AG

Headquartered in Rimbach-Mitlechtern, Germany, SPIR STAR® AG has established itself as a reliable global supplier of robust ultra-high-pressure hose systems for over three decades. The company’s specialised hose solutions are meticulously crafted in-house by expert engineers, utilizing cutting-edge manufacturing technology.

Through consistent collaboration with an extensive network of global partners, SPIR STAR® AG ensures that customers receive exceptional service, personalised consultation support, and competitive lead times, regardless of their location.