Ex eb’ Increased Safety Enclosures for Equipment for Zone 1

An increasingly frequent case for the construction of Zone 1 switchboards is the use of Ex eb enclosures for the integration of electromechanical components and/or electronic interfaces compliant with EPL Gb certification.

Premise

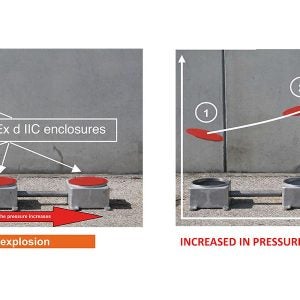

When a switchboard is needed in an area classified as Zone 1 due to the risk of explosive atmospheres, the simplest system choice is to use explosion-proof enclosures with Ex-db design. [1]

Over time, diverse needs have appeared with switchboard solutions having GRP [2] or stainless-steel enclosures based on Ex-eb increased safety enclosures.

These panels are populated with components that are, in turn, suitable for installation in Zone 1.

In the case of increased safety enclosures, the manufacturer must have equipment certificates [3] for the enclosures with components and, by respecting a series of requirements, can supply and assemble the switchboard in accordance with the certificate.

The list of certified components in the certificate of enclosure with components [3]

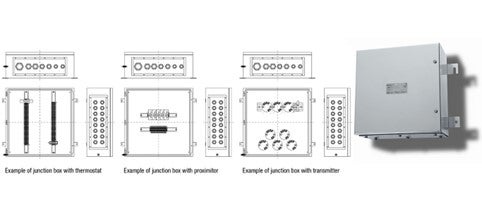

An increasingly frequent case is the the creation of panels that integrate electromechanical components and/or electronic interfaces compliant with use in Zone 1 with Gb certification and EPL. These components are mounted in various configurations in Ex- eb increased safety enclosures with the necessary customisation in terms of assembly, electrical connections, and provision for cable entry. The increased safety enclosures will guarantee IP sealing and the necessary mechanical protection.

The certificate of enclosures with components to which the panel refers shows:

- certificates of the admitted components

- specific markings

- specific conditions of use which will reflect those of the installed components.

The arrangement and calculation of the dissipated power is also of primary importance in setting up the temperature class and the maximum surface temperature of the assembly thus created.

Among the components that are most frequently installed are simple electrical and electromechanical elements, such as terminals, rotary switches, electrical contacts and indicator lights, or more complex electronic interfaces (e.g.: galvanic or Zener barriers, presence sensors, measuring instruments and Fieldbus field connection interfaces) which, in most cases, combine the intrinsic safety protection method with increased safety cable entries and encapsulation of sparking elements (Ex eb). (i.e., mb).

If the components are not listed in the certificate of enclosures with components, an extension will be necessary, a process that is usually shorter than issuing a new certificate.

Clarification is also needed: there is an exemption for cable glands, caps and threaded adapters that can be chosen without being explicitly present in the equipment certificate of the enclosure with components. [4]

Conclusions

The list of components reported in the certificate or in the use and maintenance manual is proof that the notified body has assessed the assembly of a certain certified component.

The manufacturer has no power to decide alternatives except through the extension to include the component not present on the list.