MAGNETO Special Anodes is a leading designer and manufacturer of special electrochemical anodes for a wide variety of corrosion protection applications within the marine industry.

Our comprehensive catalogue of solutions includes high-quality Keramox® mixed metal oxide (MMO) and platinum-coated titanium anodes that have been specifically designed to deliver robust impressed current cathodic protection (ICCP) for offshore constructions, including vessels, oil rigs, jetty piles, windfarms and storage tanks.

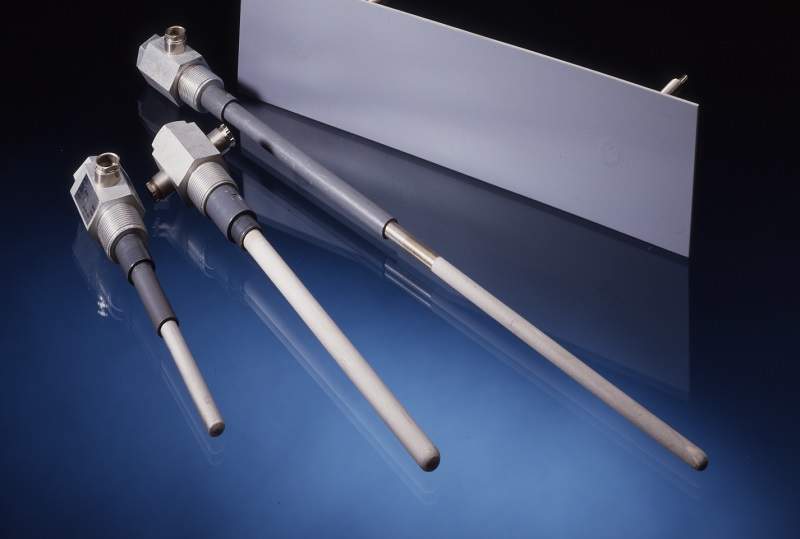

We also produce a variety of durable anode structures such as tubes, sheets, discs, meshes, wires and rods to address numerous subsea project needs.

High-performance impressed current cathodic protection (ICCP) products for offshore platforms

MAGNETO supplies an extensive range of standardised ICCP products, in addition to providing premium-quality bespoke solutions to address clients’ most stringent operational specifications when required.

Our innovative products are carefully developed using several decades of research and in-field experience in the provision of effective ICCP systems. Our engineers leverage meticulous lab testing and performance data systems to ensure each bespoke solution delivers optimum results in its intended application.

MAGNETO solutions are designed to provide dependable service throughout the project lifecycle. The company offers expert repair, refurbishment and recoating services for used anodes in order to extend the systems’ service-life, while optimising the safety and cost-efficiency of clients’ operations.

The company conducts diligent checks and verification processes throughout each stage of production to ensure excellent build quality and industry-leading performance.

Our primary manufacturing facility is located in Schiedam in the industrial centre of the Netherlands, which is close to key road, air and water transport links to facilitate hassle-free delivery and short lead-times. We also operate fully functioning production sites in the US and China for the convenience of international clients.

Customised titanium anode systems for oil and gas sites

MAGNETO’s product line primarily consists of heavy-duty titanium-based anodes, which can be equipped with substrates made from a number of different materials such as niobium or tantalum depending on the intended deployment environment.

Our versatile portfolio of special coatings includes iridium MMO, ruthenium MMO and platinum-based solutions, which each possess distinct reactive properties that allow them to achieve outstanding results across a range of marine applications. Products can also be supplied in accordance with ‘Made in EU’ certification standards upon request.

MAGNETO’s cutting-edge, ISO 9001:2015-compliant manufacturing facilities are able to produce customised anode solutions in a wide variety of sizes and configurations. These range from small-scale solutions spanning several square centimetres to larger, metres-long units, as well as in bulk capacities of up to a million pieces where required.

Our experienced team carefully tailors the size, shape and coating specification of clients’ cathodic protection anodes in order to deliver optimum performance, reliability and longevity throughout the project lifecycle.

Versatile cathodic protection solutions for industrial applications

MAGNETO’s advanced ICCP anodes can be deployed across a range of subsea applications, including providing vital protection for marine-based structures such as petrochemical platforms, harbours and windfarms, along with naval and transport vessels.

The company’s adaptable and hard-wearing products have also been relied upon to safeguard other offshore assets, including tunnels, coastal defence structures and underwater pipelines worldwide.

MAGNETO’s extensive production capabilities enable the company to provide a full array of anodes in almost every electrochemical process configuration to fulfil customers’ every operational requirement, including:

- The production of free active chlorine

- Separation, metal plating and metal-winning processes

- Water treatment, anti-fouling and disinfection operations

- Electrosynthesis activities

Our knowledgeable staff undertake collaborative research and development (R&D) projects with our customers in order to engineer new products and solutions to ensure their individual specifications are addressed.

About MAGNETO Special Anodes

MAGNETO Special Anodes is a Netherlands-based company that has been engaged in the development, fabrication and supply of high-quality corrosion protection systems since 1957.

As an industry leader in the provision of ICCP solutions, we are dedicated to delivering consistently excellent service and aim to engage in genuine, effective collaboration with all our customers to ensure dependable, long-lasting results.

We seek to establish long-term connections with our clients and many have been with us for more than 30 years, which serves as a testament to our commitment to providing premium-quality products, in-depth R&D capabilities and personalised after-sales support.