Ekstrom & Son provides world-leading expertise in vessel manufacturing for high-temperature and corrosive applications.

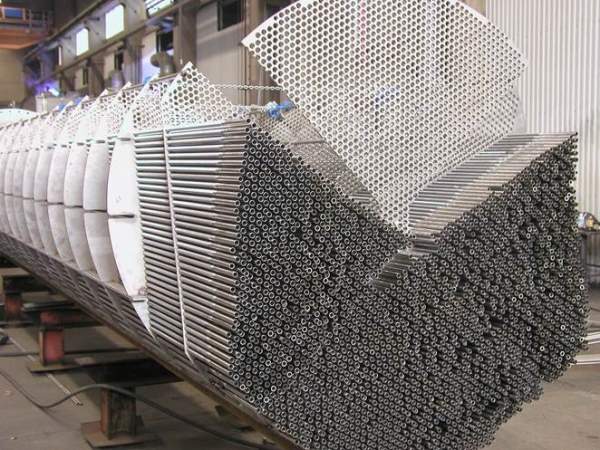

The company produces shell and tube heat exchangers and pressure vessels, including reactors, condensers, evaporators, suction scrubbers, air pre-heaters and columns.

Ekstrom & Son’s Helixchanger™ design, Smart Loop™ backflushing valves and HTFS heat transfer software create innovative solutions for our clients.

Helixchanger saves you valuable energy and space

Ekstrom & Son’s Helixchanger shell and tube heat exchangers are certified by Lummus (CB&I).

Successive baffles create continuous helical and near plug-flow conditions on the shell side enabling energy savings of up to 50%, which results in improved thermal effectiveness and enhanced heat transfer.

This also leads to fewer pressure drops, lower fouling and significantly reduced vibration hazards. Pay-back time could be as short as one year compared with a conventional heat exchanger.

Backflushing valves for plate heat exchangers

Fouling and clogging of plate heat exchangers cause problems for the industry.

Ekstrom & Son’s Smart Loop backflush heat exchangers at short intervals without interrupting the operation. By changing the direction of the flow, particles are flushed out. It also prevents biofouling, for instance, build-up of algae and other organisms.

The Smart Loop valve extends the time between maintenance periods, as well as improves performance and generates additional energy savings of up to 50%.

Customised pressure vessels

Ekstrom & Son designs vessels according to the requirements of its clients and is certified by the ASME (American Society of Mechanical Engineers) code, which is applied to plant design, manufacturing, installation, maintenance and improvement services.

The company also complies with various industrial codes, including:

- Achilles JQS, NORSOK

- ASME U; ASME UM

- ISO 9001; ISO 14001; OHSAS 18001; ISO 3834-2:2005

- Manufacture Licence of Special Equipment, China

- AD 2000 – Merkblatt HP0

Customised shell and tube heat exchangers

Ekstrom & Son is a leading designer of heat exchangers in northern Europe. The thermal design process often takes place in close collaboration with the client.

The company deploys HTFS software to develop innovative solutions for its clients’ heat exchangers.

About Ekstrom & Son

Established in 1896, Ekstrom & Son supplied columns and heat exchangers for the world’s first carbon caption storage site at Statoil Mongstad in 2009. The company designs and manufactures products in accordance with ASME, China and European engineering codes.

The company performs investigations, welding project management and non-destructive testing such as X-ray and ultrasounds.

In addition to standard stainless-steels, Ekstrom & Son works with speciality materials, including:

- Duplex and super duplex

- High-alloy and austenitic steels

- Nickel and high-nickel alloys

- Titanium

- Zirkonium