gat is a specialist in automation systems and installations for the chemicals industry. Over the last 25 years, gat has grown into an experienced service provider in electrical, instrumentation, control and automation engineering.

In order to meet the steadily growing requirements in globalised markets, gat provides modern concepts for more efficient plants and increased profitability. After comprehensive analysis, gat identifies branch, business and project-related requirements and prepares optimised automation solutions.

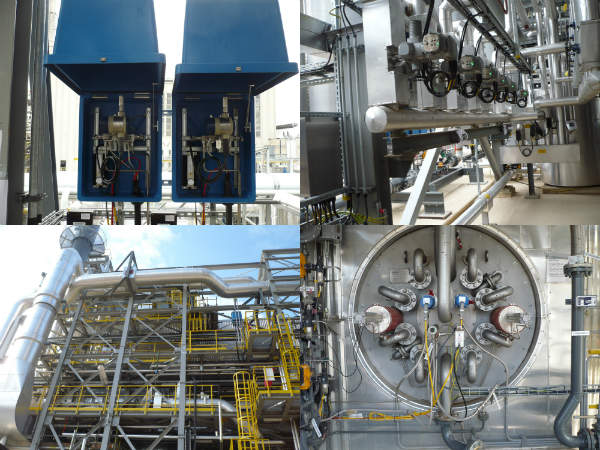

Engineering, project planning and construction

In the field of modern electrical, measurement, control and automation engineering, gat has planned and implemented more than 2,000 projects.

On that basis, the company develops customised solutions according to the particular project-specific requirements, from the basic engineering with a list of measuring points and instruments, to detailed designs with device specification sheets, circuit diagrams and functional descriptions.

Functional safety is gat’s day-to-day business, including conception, implementation and proof according to IEC61511. For this work, gat employs TÜV certified FS-engineers and programmers.

The appointed project engineer assists clients throughout the entire project. Close and direct cooperation allows quick and efficient project handling, even if the project plan is modified.

Process control engineering / central building control systems

The automation of processes guarantees transparent and constant production and improves safety, quality and efficiency.

gat develops solutions that suit the clients’ detailed requirements by choosing the appropriate process control system and visualisation, especially for fail-safe and high-availability applications up to SIL 3. The company is a certified partner for major suppliers of control systems.

For frictionless communication in production or building automation, gat also engineers and implements the corresponding high-performance and fail-safe networks and bus systems. For this purpose, the company visualises processes, structures, functional chains, procedures or shops to enable the client to completely control its plants.

Core activities in industrial automation include:

- Programmable logic controllers: S5, S7, S7-1200, S7-1500, ControlLogix, H41/51, HiMatrix, HIMax

- Control systems: PCS7, DeltaV, Freelance

- Central building control systems: Desigo Insight, SAIA PG5 Controls Suite, B-CON

- Process visualisation: COROS, WinCC, WinCC flexible, Factory Link, Intouch, RS View

- Industrial bus systems: DP2/L2, H1, DD, PA, Modbus, Profinet, ASi, Ethernet, CAN, BACnet, LON

Do you use legacy or exceptional hardware or software? No problem; please contact gat.

Production and installation of control cabinets

On request, gat manufactures and delivers ready-for-connection switch and control cabinets, according to the client’s wiring and circuit diagrams, construction plans and applicable standards. The cabinets can also be installed in containers.

gat’s installation team offers extensive knowledge in the areas of switch room and measuring station construction, complete field installations, process measuring and control instrumentation with cable route construction and cabling, as well as for process air and supply air piping.

Due to its experience in the chemical industry, oil and gas plants, power plant construction and plant engineering, gat offers clients extensive knowledge of installation engineering and requirements, especially in explosive environments.

Reliable and safe automation systems

gat works out solutions for highly specialised requirements. The certificates and approvals for gat’s integrated management for quality, safety, health and environment are evidence of its expertise and guarantee consistently high standards of quality.

These certificates include:

- DIN EN ISO 9001:2008

- Safety certificate contractor (SCC**)

- Certificate of specialisation according to §19 I Water Resources Act (WHG)

Power plant commissioning and maintenance

The successful commissioning of a plant is not the last step of gat’s range of services. For long-lasting use, safety checks and maintenance of power plants are necessary at regular intervals. gat has a long experience in this service sector and is a reliable partner for a successful future.

Customer-orientated service

gat’s profile is characterised by its customer-orientated flexibility. The company develops solutions with its clients as needed, taking into account any specific requirements.