Seal Saver® provides custom protection solutions to suit the specific needs of your cylinders.

We offer a variety of material options to protect your cylinders in various environments and suit their specific needs. We also create field installable, unique designs for our customers’ cylinders.

Each Seal Saver product is designed to meet specific job site and environmental requirements, and custom-engineered to provide the best fit for the cylinders that they are installed on.

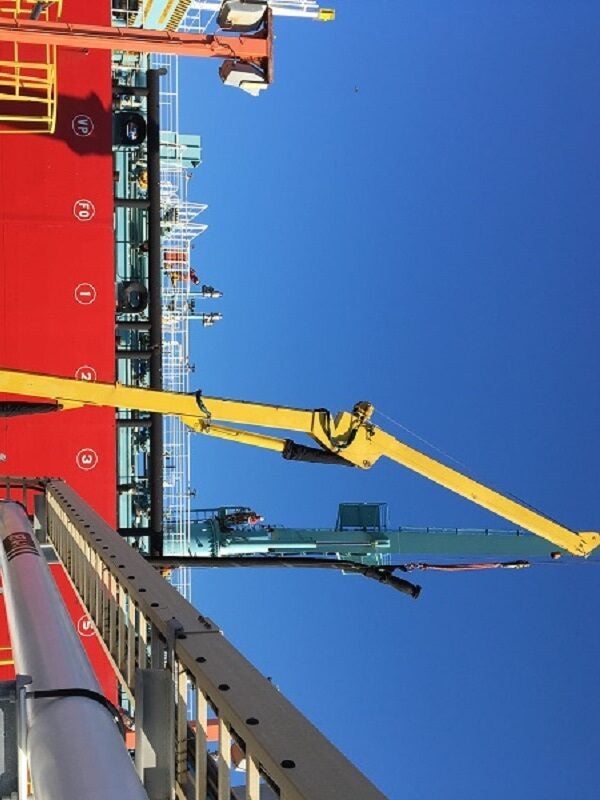

Easy-to-install cylinder protectors for offshore industries

Our cylinder protectors are designed to be easily installable anywhere and prevent chrome pitting due to chemical washes. There is no need to disassemble any part of the cylinder and all that is usually required for installation is a screwdriver and one person. The average time spent installing one of our boots is five to ten minutes.

Additional key features and benefits include:

- Minimal rod scoring

- Extendable cylinder seal lift

- Heat, oil, chemicals and water resistant

- Protection against dirt and corrosion

Cost-effective preventative maintenance

Cylinders can fail for various reasons. When your equipment is down due to a cylinder failure, every minute wasted is money deducted from your bottom line and the cost of repairing or replacing failed cylinders is yet another expense cutting into profit.

Installing a Seal Saver on your cylinder will help to significantly slow down or even stop this repair cycle down. Our solution ensures return on investment as it prevents cylinder damage. It is one of the simplest and most cost-effective preventative maintenance tools available.

Custom-design cylinder protection solutions

We offer custom sizing designs and a variety of material options so we can offer a solution to meet your requirements. Our most popular materials include ballistic nylon, Kevlar and Silica-based textiles.

These options allow end-users the flexibility to decide which material will be the most appropriate for their applications, such as extreme weather conditions on land or marine environments.

Seal Savers are made using durable, high-quality materials and manufactured in the USA.

About Seal Saver

The Seal Saver Custom Cylinder Protection product line was established in 1985 by Fluid Control Services after discovering that there was a real need for cylinder protection that could be field installable.

From the beginning, it has been our goal to produce high quality, high-performance products for our customers to help reduce, or even eliminate, the expensive costs associated with cylinder failure.

As the years have progressed, so has our ability to design protective covers that can be successfully used across a wide range of industries.