Flint Subsea is a specialist supplier of emergency quick disconnect (EQD) systems to the offshore oil and gas industry for subsea and topside projects.

All the EQD systems are designed to protect personnel, the environment and infrastructure. In the event of an emergency, EQD devices separate and valves close to prevent the contents of the hose discharging to the marine environment.

The Flint Subsea range of emergency quick disconnect devices includes mid-line, subsea and vessel to platform EQDs. In all cases, the devices use the same technology and can be pulled apart or activated remotely utilising the on-board hydraulic disconnect cylinder.

Mid-line EQD solutions for marine environments

The mid-line EQD is a full-bore, straight through, pressure-balanced EQD device suitable for operating up to 3,000m and 690bar working pressure. In the event of an overpull on the attached hose, the tension pins will be broken and the unit will separate.

Internal barriers will close off to prevent discharge of fluid to the marine environment. The mid-line EQD is available in 2in and 4in bore diameters, with a range of end connections including flange, hammer union and hub.

Vessel to platform EQD system for oil and gas operations

The vessel to platform EQD system comprises a pressure balanced breakaway connector, which is mounted on deck or mid-line in a hose. It is held together with prestressed tension pins designed to break at a predetermined load. Pins break when the hose tension exceeds their strength, initiating the disconnect sequence. Once disconnected, the valves seal prevent discharge from both ends of the connector. The design ensures that marine discharge is minimised in the cycle.

Hold back clamps hang the unit over the side of a vessel or platform, and are available to suit the EQD. The unit is also offered with hydraulic override capability, allowing it to be actuated remotely should it be required for the vessel emergency shutdown (ESD) system. The vessel to platform EQD system is available in a number of connections options similar to the mid-line product.

Subsea manifold systems for offshore vessels

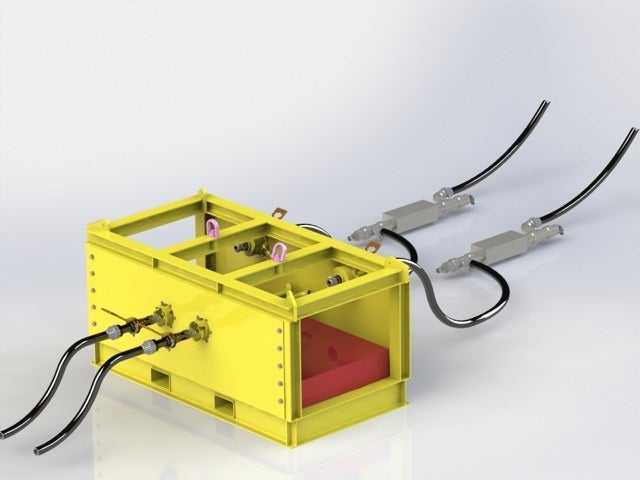

The Flint Subsea EQD Skid is a subsea manifold system enables the operator to decouple operational loads from the infrastructure it is connected to. The downline from the vessel is connected into the skid using hot-stabs, and a jumper connects the skid to the subsea asset. The on-board clump weight ensures vessel motions or EQD loads are isolated in the skid.

In the event of a disconnection, the built-in fail-close actuator will shut off the ball valves, isolating the subsea asset until access can be re-established safely. The skid can be supplied with all associated equipment, included slings, hot stabs and hold-back wires. It can be used in conjunction with the mid-line EQD to provide complete protection.

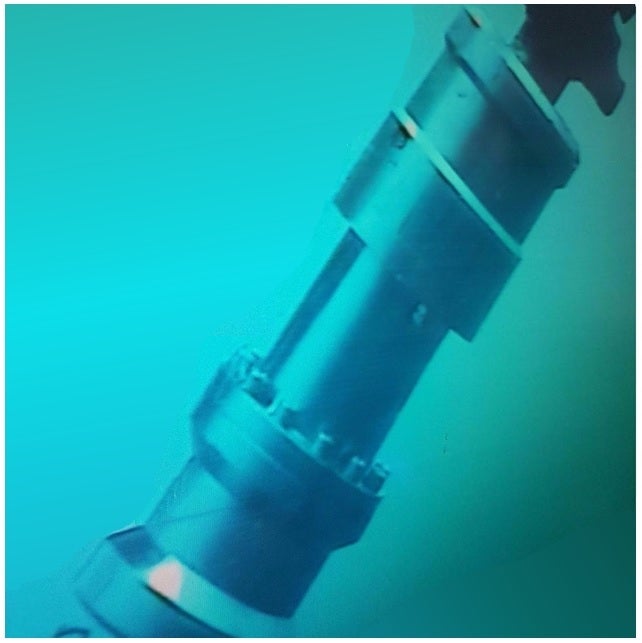

Hot stabs for subsea exploration

Flint Subsea is experienced in the design and qualification of customised and standard subsea hot stabs and connection systems. Bore diameters of 1in through to 4in are available and a range of pressures from 1,000psi to 15,000psi can be accommodated through the careful selection of materials and dimensions. The hot stabs are available with a variety of ROV interfaces, including fishtail, D-handle and T-bar.