Johnson Industries develops a wide variety of products in-house, including hydraulic, pneumatic, spring-set and manually applied calliper disc brakes, as well as brake systems for rotating equipment within the offshore industry.

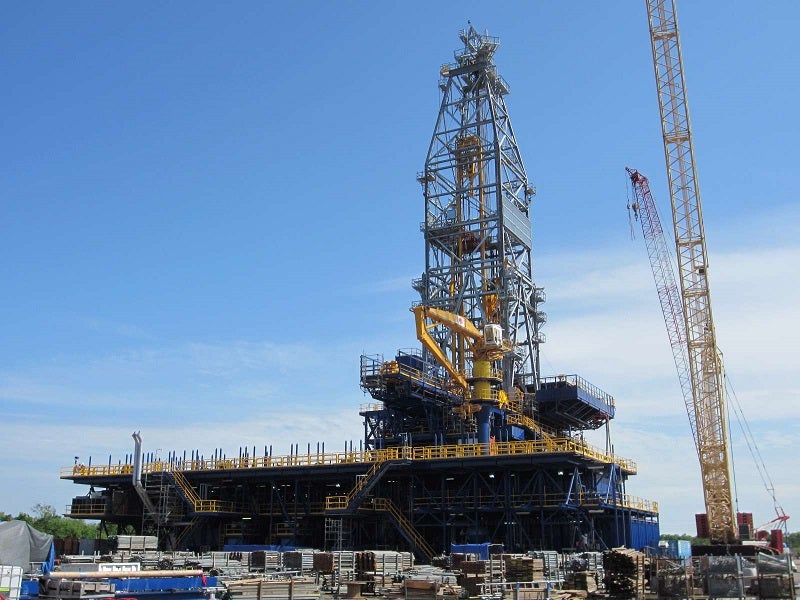

The oil industry has specific challenges for both onshore and offshore equipment. The Offshore Drawworks equipment is a winch system for creating pipe connections beneath the Earth’s surface for drilling into reservoirs of oil.

As the load increases, braking systems require an ever-increasing amount of brake torque because of the depth drilled. Each piece of drill pipe causes an increased load as the drill string reaches further into the drill hole until the desired depth is reached.

Under this kind of stress, brake systems require cooling. This can be managed through either water-cooling or air ventilation at the brake disc. Brakes are typically either hydraulic or pneumatic versions. We manufacture to API, DNV, UL/CSA, and ABS specifications.

We manufacture electro-magnetic and electro-hydraulic thruster drum and disc brakes which are used internationally on material handling and power transmission equipment.

Brake discs, flywheels, brake drums and transmission couplings

Our catalogue encompasses standard diameter brake discs and flywheels.

These can be supplied with or without mounting holes, hub, straight bore, tapered bore, keyway, scribed bolt circle, dynamic balancing and/or forged ventilation holes.

Johnson Industries manufactures various models of brake drums, including standard, offset, bore and keyway, and rough stock bore. We also offer many types of transmission couplings for brake applications.

Brake discs and drums can be tailor-made according to customer specifications.

Storm brakes and emergency braking systems for rail-mounted equipment

The company provides storm brake systems, which include automatic and manual rail clamps, rail brakes and wheel clamps.

Emergency braking systems are useful in industries involving cranes, stacker-reclaimers, loaders and other types of rail-mounted equipment.

Parts, services and compatibility for offshore operations

Johnson Industries maintains an extensive selection of parts, including the entire range of Elhy / Eldro thrusters, as well as offering services for maintenance and refurbishment, on-site service, training, and commissioning.

A range of hydraulic power units, pneumatic power units, and electrical control systems compatible with Johnson Industries brakes are also available.

About Johnson Industries

From our regional offices and factories in Canada and the UK, Johnson Industries provides an extensive range of industrial brakes and brake systems to an international market.

Established on 27 April 1966, Johnson Industries’ first corporate office and factory were opened in Richmond, British Columbia (BC), Canada, in 1974.

In 1993, Johnson Industries bought Elevanja, which has been designing and manufacturing electric brakes since 1915. This acquisition has enabled us to diversify our brake line.

Our second office opened in Toronto, Canada in 1997, with a focus on our eastern clients. On 25 October 2005, we moved into an advanced manufacturing facility in Delta, BC, Canada.

The field of electrical engineering began rapidly developing in 1913 and the three founding directors agreed to incorporate their skills, to create an electrical engineering services and solutions company.