Located in north-east England and a member of NOF Energy since 2007, Site and Field Services (SAFS) specialises in the manufacture of fabricated and machined components for the offshore, petrochemical, construction and heavy engineering industries. Established in 1999, the company has grown and developed by working with and listening to the needs of our customers.

Our success is based on the simple principle of offering excellent service and products that meet the demands and specifications of our customers, on time and on budget. Our aim is to be regarded as your production engineering department, working with your design engineers throughout the process from conception to completion.

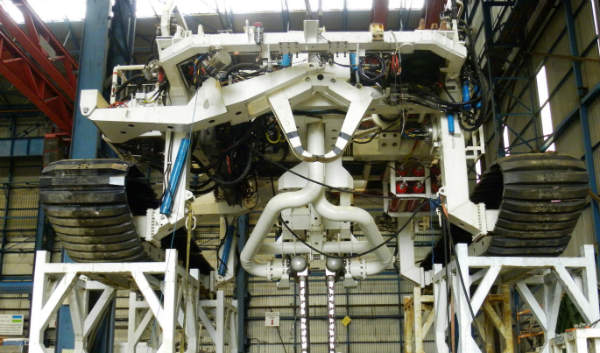

SAFS has the facilities to manufacture, fabricate, weld, precision machine and mechanically assemble, all within the confines of a single site. We offer an unrivalled ‘Resource for Industry’.

Fabrication and welding services

Site and Field operates from modern 18,000ft² fabrication facilities with 15t and 30t overhead lifting capacity cranes, a 14,000ft² machine shop and a further 32,000ft² of secure outside storage.

We work with carbon (including RQT, Hardox and Corten material), stainless and duplex steels and aluminium, specialising in the production of subsea and topside components for the oil and gas sector plus bespoke bridgeworks and general structural fabrications for the construction industry.

Our welders are coded to BS EN 287, AWS D1.1, ASME IX and EN ISO 15614 and are compliant with most offshore standards, including NORSOK M101 and M601.

We are also coded for welding of Duplex pressure vessels to PD5500.

Subsea pipeline products

SAFS has extensive experience in the supply of subsea pipeline products, including:

- Umbilical terminations

- Pulling eyes

- Hang off collars and flanges

- Bend limiters

- Seabed clamps

- Weak link and repair splices

- Split clamps

- Pulling cases

- Main casings

- Mud mats

- Underwater termination assemblies

- Anchor swivel terminations

- Subsea distribution units

- Shipping baskets

- Pressure vessels

Topside equipment

On topsides we can offer the manufacture of overboarding and deployment equipment, A & R equipment, hose reelers, choke and kill manifold frames and much more. Contact us using the details below for a quick response to your enquiry.

Precision machining services

SAFS offers a sub contract precision machining service manufacturing components and sub assemblies for the oil and gas, railway, defence, pharmaceutical, marine and hydraulic component industries. We can offer a full range of machining services:

- CNC and manual turning

- CNC and manual milling

- Vertical and horizontal boring

- Drilling and slotting

SAFS offers a full range of CNC and manual precision machining services. We machine components in carbon and stainless steels, aluminium and plastics in small to medium batches.

Our range of equipment is comprehensive and investment in new machine tools is constantly under review to maximise our capabilities.

On-site welding and machining services

If you prefer or need to undertake modifications or repairs to equipment at your own premises, we have a team of skilled welders and machinists available. Capabilities include:

- Line boring

- Facing

- Drilling and tapping

- Fabrication and welding

- Thermal lancing

- Mechanical fitting

We maintain a fleet of mobile vehicles equipped with all the required welding / machining gear needed to complete the job.

All SAFS site personnel are fully trained in carrying out risk assessments and method statements prior to beginning work, in line with health and safety regulations. They have been issued with site safety passports and are fully conversant with current safety requirements, including use of scaffolding, moving platforms and working at height.

Quality assured

We are committed to achieving exceptional service for our clients in respect of quality, delivery and value for money.

We hold ISO 9001:2008 and ISO 14001 accreditations and regularly work with Lloyd’s and DNV third party inspections.

SAFS has more than 50 years of experience working closely with the designers and project engineers from major oil and gas suppliers around the world. The SAFS team consists of a unique combination of people, skills and assets that can rapidly respond, working with our customers in a supporting role to ensure that problems are solved and that jobs are completed on time, within cost and at the agreed quality.

Give us a call or use the form below with your enquiry to see what we can do for you.