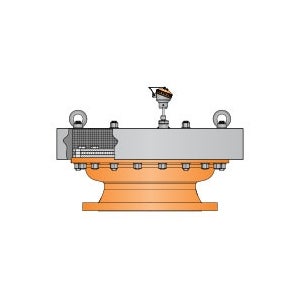

Elmac Technologies, the international manufacturer and distributor of flame arresters and tank and vessel protection equipment, announces the expansion of its current end-of-line flame arrester range with a new short-time-burn ESA series, suitable for use with gases in explosion groups IIA1 and IIA, as well as elevated operating temperatures up to 150°C.

Elmac commercial manager Andy McGlynn said: "The ESA series of short-time-burn flame arresters represents another success for Elmac Technologies. Not only does it ensure we have a product range that meets (and often exceeds) the challenging functionality and performance levels our customers require in a unit of this type, but we have been able to utilise and enhance the technology implemented in our recent EVA, EVB and EHB series of arresters and extend it to the ESA."

The ESA is different to Elmac’s other end-of-line flame arrester products in that it offers short-time-burning protection, as well as standard deflagration protection. Short-time-burning occurs when a flame stabilises on the surface of the flame arrester elelement after a deflagration has occurred. The extra protection afforded by short-time-burn arresters allows time for secondary protection measures to be implemented, in order to quench or extinguish the flame.

Andy McGlynn added: "Our product development team has managed to combine the benefits of short-time-burn, elevated operating temperature, excellent flow capacity and ease of maintenance (E-Flow™ technology), into one compact lightweight series of flame arresters. Even though I’m slightly biased, I think that’s quite an achievement."

The Elmac development team used computational fluid dynamics (CFD) techniques to design and optimise an enhanced crimped-ribbon flame arresting element for the ESA series, which delivers market-leading performance for high flow capacities with minimal pressure drop.

At the same time, the unique element design makes the arrester less susceptible to fouling and clogging, while reducing the overall weight of the arrester, thus improving its ease of installation and maintenance.

Features and benefits of ESA flame arresters include:

- Short-time-burn for early warning of stabilised burning event

- Extended upper operating temperature limit (150°C)

- Exceptional flow capacities with minimal pressure drop

- Easy-clean, replaceable, crimped-ribbon elements

- Unique element design is less susceptible to fouling / clogging

- Size range from 15mm to 600mm nominal bore

- Material options include carbon steel, stainless steel, duplex steel and Hastelloy

- End connections include flanged or threaded options

- Arresters can be painted or coated as required

- Bird screen fitted as standard