PREZIOSO Linjebygg

Inspection, Modification and Maintenance Solutions for Offshore Installations

PREZIOSO Linjebygg provides modification and maintenance services for oil and gas installations, power generation stations and plants, and infrastructure such as bridges and tunnels.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

PREZIOSO Linjebygg provides modification and maintenance services for oil and gas installations, power generation stations and plants, and infrastructure such as bridges and tunnels.

The company specialises in the use of rope access techniques for hard-to-reach locations, advanced lifting and rigging solutions in areas with limited crane access, and developing remotely operated tools fixed to the installation for optimal stability and precision, such as for splash zone operations, and internal tank / vessel inspection. In addition, the company delivers complete ISS-services (insulation / surface treatment / scaffolding) in their markets.

Multidisciplinary technical and engineering services for offshore and onshore platforms

PREZIOSO Linjebygg’s services cover insulation, scaffolding and surface preparation / treatment (ISS); inspection; modification; concrete rehabilitation; non-destructive testing (NDT) / welding inspection; mechanical trades; cutting and decommissioning small components; AIM (asset integrity management); and inspection planning.

Many of the company’s inspection, modification and repair (IMR) solutions can be used while the installation is in its normal operation state.

Rope training and access solutions

PREZIOSO Linjebygg’s multidisciplinary rope access personnel perform a wide range of tasks in hard-to-access areas, such as NDT inspection, dropped object surveys, surface preparation and treatment, insulation and PFP application, traditional maintenance and repair, cutting / decommissioning small components.

Rope access reduces, and in certain cases eliminates the need for scaffolding or other traditional and often less cost-effective solutions.

Rope Access certification, including all levels of training, are available according to both the international Industrial Rope Access Trade Association (IRATA) regulations, and Norway’s SOFT standard.

Customised lifting and rigging appliances for offshore installations

Smart designed modular parts, which in combination with high-speed winches make a standalone and self-supported installation. Special lifting appliances such as the GOA® have been designed, engineered and tailor-made by PREZIOSO Linjebygg’s engineering department.

Typical projects undertaken by the company include flare tip replacement (without helicopter support); lifting heating, ventilation and air-conditioning (HVAC) units; oil / gas coolers; jack-up platform leg gearboxes; and flare riser spool parts, generators or structural platform steel parts for high-elevated locations.

TopsideATEX cold cutting with diamond-wire

PREZIOSO Linjebygg’s ATEX-certified diamond-wire cutting kit for cold cutting in explosive areas (zone 1), for removal and modification allows for on-site operations without shutting down production.

Composed of a small but powerful hydraulic power unit (980kg), and an adapted diamond-wire saw, the kit provides easy handling and access to confined spaces when required.

Diamond-wire cutting has proven its efficiency in traditional rock cutting applications, as well as cutting black steel, super duplex, S316, titanium, concrete encased steel beams, heavily reinforced steel encased concrete, and embedded steel structures.

The company also has developed a special subsea diamond-wire saw, which can easily be adapted for cutting various pipe and leg dimensions so no remote-operated vehicles (ROV) or diver support is required.

Riser and structural repairs

PREZIOSO Linjebygg’s Cofferdam solution provides a dry working habitat for repair of risers and jacket structures in the splash zone area, without having to shut down the platform.

The equipment can be customised to suit the needs of each specific project.

The company’s supervisors make site inspection visits to assess and evaluate the requirements, while the engineering team prepares 3D computer-aided design (CAD) models and scans of the relevant installation structure for adaption to the specific riser or pipe / jacket structure.

The Cofferdam can be adapted for use also on plane surfaces, such as ship hulls.

Piping system inspection and repair services

Inspection and repair of corroded pipe systems while still under operational conditions is another LBO solution that reduces shutdown times. Straight pipe span lifting tables are generated for individual piping classes, for controlled lifting of pipes, providing access to corroded, or suspected, areas.

The company’s services include activities such as stress calculations, lifting tables and planning, clamp removal, lifting of pipes and surface treatment, as well as pipe re-positioning / installation.

Remote cleaning and inspection services of process vessels

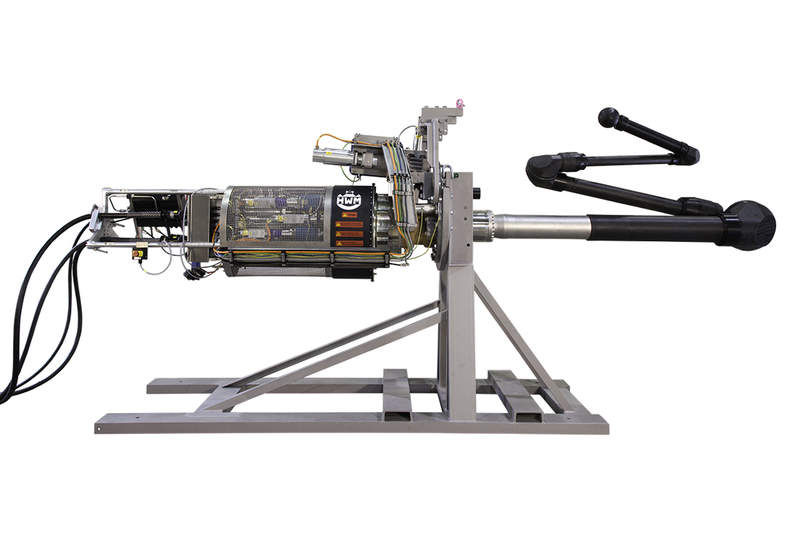

The Telbot® Classic ATEX is an advanced robotic arm especially developed for internal cleaning and inspection of process vessels.

The arm has a horizontal reach of six metres, and a maximum height of five metres. It can automatically access pre-programmed areas inside the vessel, and all movements of the arm are repeatable using the software application.

The robot arm is fitted with a high-pressure flushing system delivering up to 150bar of spray pressure for efficient cleaning of dirt and grime before inspection. The arm and flushing system is ATEX certified for use in zone 0, with the exception of the camera that is zone 1.

Remote IMR operations in the splash zone

Remotely operated tools temporarily fixed to the installation avoids the use of divers or ROVs.

The Splash Zone Technology includes a range of field-proved access tools to fit different areas of use, such as offshore oil and gas installations, offshore windmills, fjord-crossing bridges or any other structure exposed to ocean waves and currents.

Applications include surface cleaning, visual and NDT inspection, cutting and removal, retrofit anodes, and other repair and installation work.

The PREZIOSO Linjebygg history

The Prezioso company was founded in France in 1957, with a focus on coatings for industrial applications. Sustained growth in the 70’s and 80’s with two main drivers: construction of nuclear power plants in France, and strong development of the oil and gas markets in the Middle East.

It was soon awarded significant maintenance projects, and later extended its business into insulation, scaffolding, rope access and inspection services. A major acquisition of Linjebygg Offshore (Norway) lead to a new corporate identity in 2014: PREZIOSO Linjebygg.

The PREZIOSO Linjebygg Group is owned by Altrad (France) and a workforce of more than 20,000 employees worldwide.

Contact Details

Website

Email Address

Address

6415 Molde,

Norway