Sonometric Inspection offers professional non-destructive testing and rope access services to the construction, petrochemical and marine industries. All services offered are in accordance with ISO 9001:2008(E) requirements.

Surveys are conducted by specialists with internationally recognised experience in many fields. They are certified to SNT-TC-1A standards and operate in line with international standards and classification society requirements.

Our services have been approved by the following classification societies: Germanischer Lloyd, Lloyd’s Register of Shipping, Det Norske Veritas, Bureau Veritas, Russian Register of Shipping, RINA and the American Bureau of Shipping.

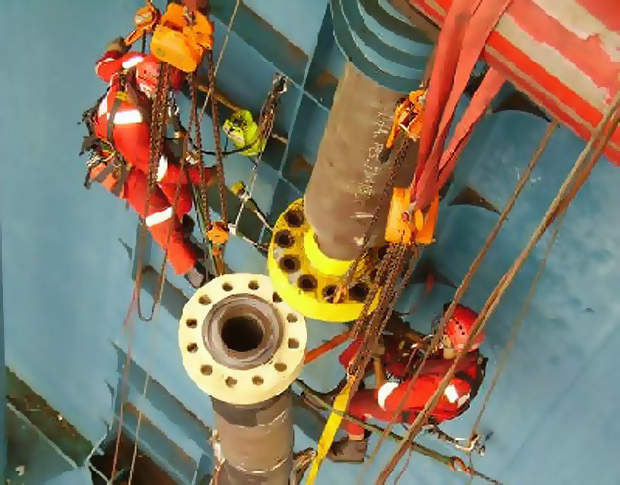

IRATA-qualified rope access specialists

Rope access specialists with IRATA qualifications are assessed and certified to international standards and have over nine years of experience, with a 100% safety record.

Non-destructive testing and rope access services

We provide the following range of non-destructive testing (NDT) and rope access services for the offshore industry:

- Liquid penetrant testing

- Magnetic particle testing

- Ultrasonic testing

- Gamma and X-ray radiographic testing

- Digital wall thickness measurement

- Hardness testing

- Photographic and close-up surveys

- Rigging and rope access services

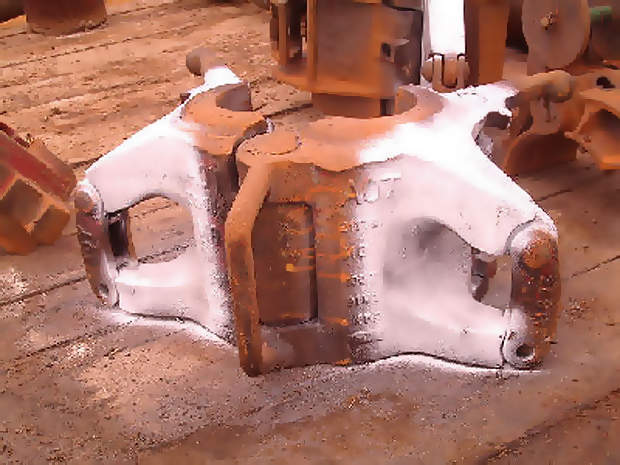

Liquid penetrant testing for components and welds

We provide effective surface-opening flaw detection tests on non-porous ferrous and non-ferrous components and welds with non-halogenated red solvent removable dye, fluorescent solvent removable dye, red water washable dye and fluorescent water washable dye.

Magnetic particle testing

We offer high-sensitivity crack detection testing on ferrous-magnetic components and welds with AC or permanent magnet portable yokes. Fluorescent and colour contrast inks and powder are provided for low and high-temperature conditions.

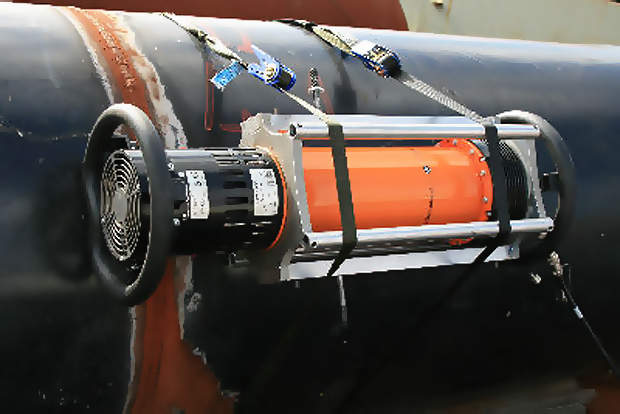

Ultrasonic testing for metals, plastics and composites

We provide pulse echo ultrasonic flaw detection, which is widely used to detect and characterise hidden internal defects in engineering materials such as metals, plastics and composites. High-frequency sound waves reflect from cracks, voids and other material discontinuities, producing distinctive echo patterns.

Gamma and X-ray radiographic testing

Because of the penetration and absorption capabilities of X and gamma radiation, radiography is used to test a variety of products such as weld, castings, forgings and fabrications.

Radiographic testing is one of the primary non-destructive test methods in use today. It requires exposing film to X or gamma rays that penetrate a specimen, processing the exposed film and interpreting the resultant radiograph.

We offer a transportable industrial X-ray unit or gamma ray Iridium192 sources, with a penetration capacity up to 60mm in steel with a 16min exposure time.

Digital wall thickness measurement for pipes, vessels and plant equipment

We offer pulse echo, ultrasonic wall thickness gauging of all types of known and unknown materials on pipes, vessels and plant equipment for the evaluation of diminution loss for class or owner’s condition of survey with multiple echo function, to provide accurate thickness gauging through paint coatings without chipping or damaging the coating.

Hardness testing for welds and other materials

Hardness testing is used on welds, heat-affective zones and base materials to detect hardness. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. Simply put, when using a fixed force (load) and a given indenter, the smaller the indentation, the harder the material.

We offer hardness testing on the following makes: Brinnell, Shore, Rockwell and Vickers.

Photographic and close-up surveys

Digital photography is carried out by us with, as a minimum, a 10MP camera and an 18mm-55mm lens. The final report is compiled in detail, then printed in high image quality and supplied with a compact disc.