Tim Cousins Australia is a multidisciplinary forensic firm that performs numerous investigations entailing failure of assets, defective materials, industrial accidents, property damage and intellectual property matters for the insurance, commercial and legal sectors.

We can assist clients with the coordination of multidisciplinary and complex investigations, including forensic services, condition survey, laboratory and field testing, consultation services and field examinations.

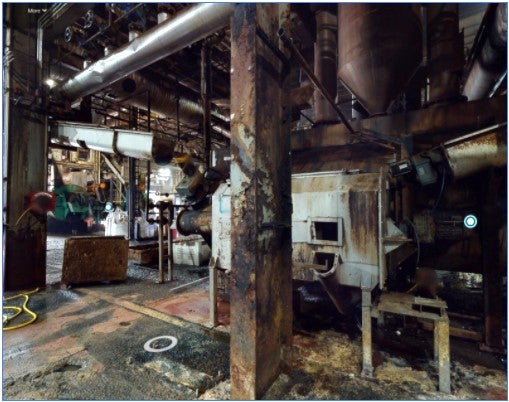

Expert analysis and inspection for oil and gas facilities

Tim Cousins Australia comprises a highly experienced professional team including metallurgists, engineers, technologists, material scientists and inspectors. The team offers high-quality customer service that fully complies with the company’s ethics and regulations, ensuring that services are efficient and cost-effective.

We perform in-depth investigations in accordance with the specification requirements outlined in the American Society for Testing and Materials (ASTM), the Society of Automotive Engineers (SAE), the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), which make us uniquely qualified to investigate all types of material failures, particularly metals, ceramics and polymers.

We can assist clients with the coordination of multidisciplinary and complex investigations, including laboratory testing and field examinations.

Materials failure analysis of metals, ceramics and polymers in the offshore sector

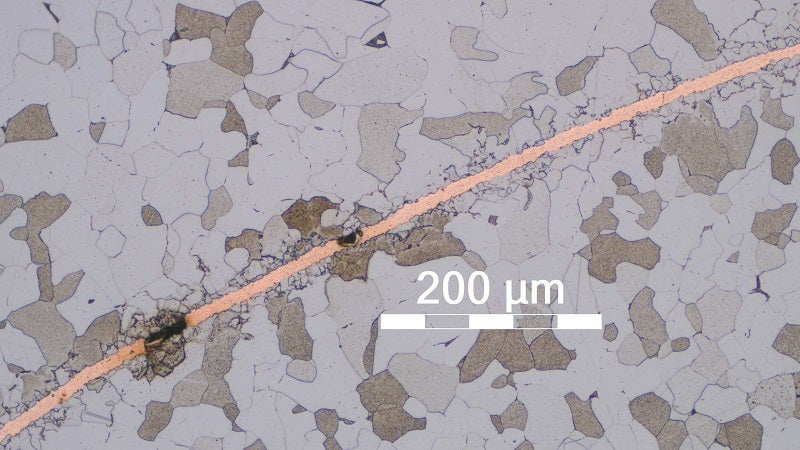

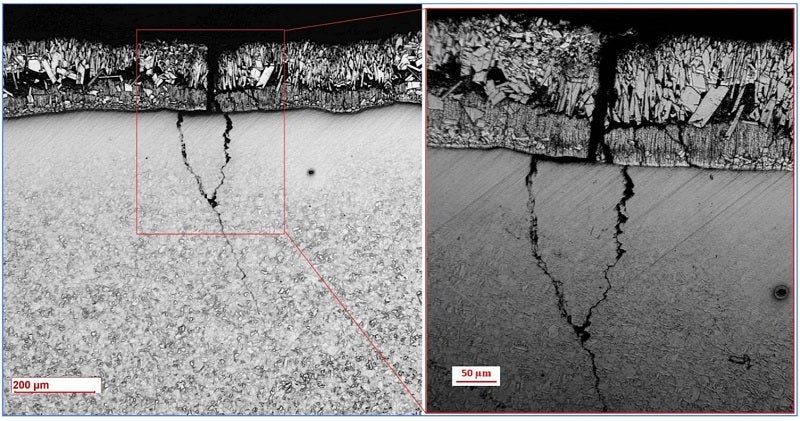

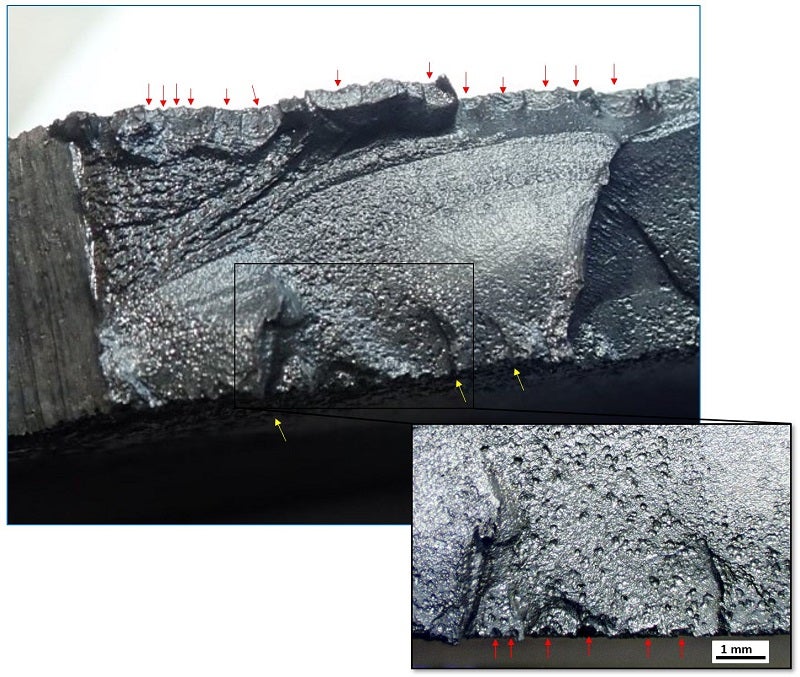

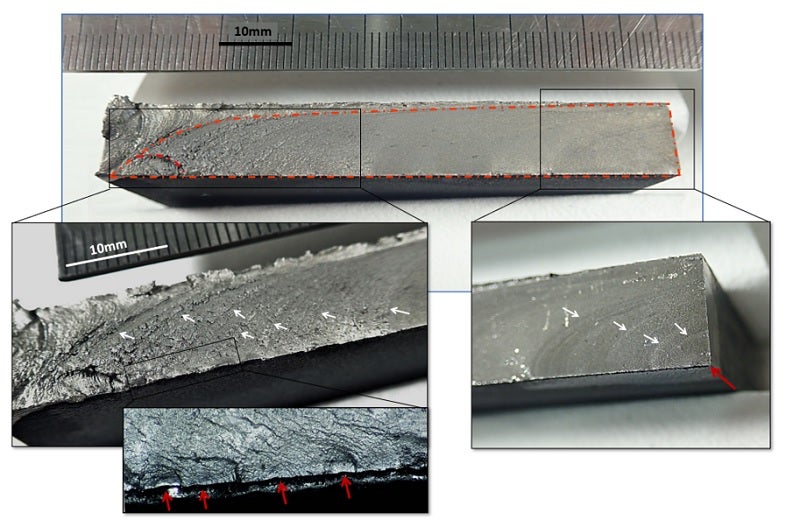

Tim Cousins Australia provides sophisticated, rigorous failure analyses involving a variety of products and materials using a wide range of analytical techniques such as Optical Profilometry, Scanning Electron Microscopy, Fourier-transform infrared spectroscopy, X-ray spectroscopy and Gas chromatography–mass spectrometry. to conduct material failure analysis on physical and environmental assisted degradation processes such as:

- Fracture

- Fatigue

- Wear

- Cavitation Erosion

- Radiation Damage

- Stress Corrosion Cracking

- Corrosion Fatigue

- Fretting Corrosion

- Cavitation Corrosion

- Radiation Corrosion

Our familiarity with industry standards such as the American Society for Testing and Materials (ASTM), the Society of Automotive Engineers (SAE), the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) makes us uniquely qualified to investigate all types of material failures, specifically metals, ceramics, and polymers.

Desktop assessment and review

Desktop assessment is an evaluation of documents and evidence from a desktop rather than in the field.

This is used in various circumstances, including inadequate or limited availability of documentation for review, site visit unavailability, restricted budget, or limited time for full assessments.

Our experts review all data from a desktop and provide expert analysis of product failures in a wide range of industries such as oil and gas, mining, marine, transport, agriculture, water industry and insurance.

Expert inspection and testing

Tim Cousins comprises a highly licensed professional team that includes metallurgists, engineers, technologists, material scientists and inspectors. Given the diversity of our professionals, clients will always be assured by the performance of the most cost-effective inspection regime that will comply with the regulatory requirements.

This investigation happens in the place of field enquiry in cases such as lack of sufficient documentation, inability to visit the field, budget or time constraints that do not allow for a more complete review.

Legal and forensic presence

Our team provides independent failure analysis services for contentious matters entailing investigating material failures, mechanical failures, electronic and electrical engineering system failures.

The Tim Cousins Australia team investigates and prepares high-quality forensic failure reports on contentious issues involving material, mechanical, electronic or electrical engineering failures and more. This helps resolve disputes through expert evidence and detailed professional reporting.

The company’s experts have provided reports and given expert evidence in the Australian Courts resolving complex multidisciplinary conflicts.

Secure evidence storage solutions

Tim Cousins Australia offers solutions for evidence storage, where forensic evidence can be securely placed for current or future processing.

Our evidence storage facility is proficiently managed and the most secure storage space is located in the laboratory, which is closely monitored with full closed-circuit television (CCTV) and alarm coverage.

Access to the storage facility is regularly reviewed and restricted to a limited number of employees. The storage is also protected from forced or unauthorised entry, as well as potential environmental threats.

Tim Cousins Australia offers secure evidence storage, which is dedicated space for the sole purpose of securely storing forensic evidence that the forensic laboratory may process or has processed.

Our secure evidence storage facility is supported by robust evidence management. Evidential storage is the most secure storage area in the forensic laboratory and the most rigorously controlled area with full close circuit television (CCTV) and alarm coverage. All access is regularly reviewed and limited to the minimum possible number of employees.

Our secure evidence storage facility is designed so that it can withstand any forced or otherwise unauthorised entry, as well as any environmental threats.

Condition survey and diagnostics

Before undertaking any action, it is essential to ensure that the main causes and extent of defects are properly evaluated so that the most cost-effective and technically sound rehabilitation solutions can be specified.

At Tim Cousins Australia, we have extensive experience in Diagnostic investigations for all types of structures and, in particular, for all corrosion-related problems.

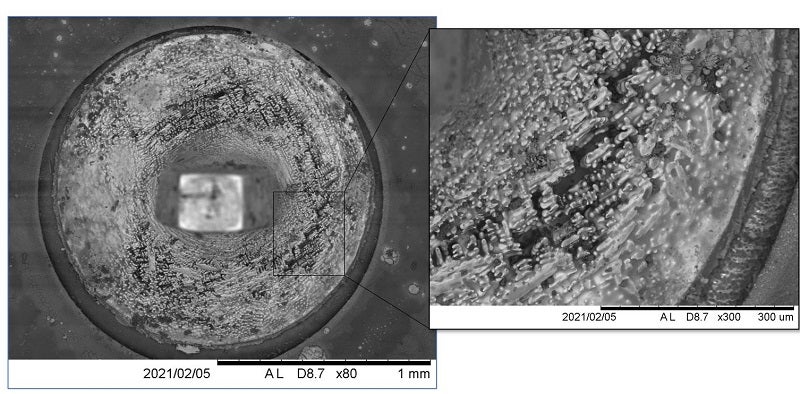

Fractography (metals, ceramics, polymers)

Fractography is a valuable aid to mechanical property testing and a powerful method to determine the cause of materials failure in forensic engineering. Our experienced fractographers at Tim Cousins Australia provide technical fractography services for a broad range of materials, including metals, ceramics and polymers.

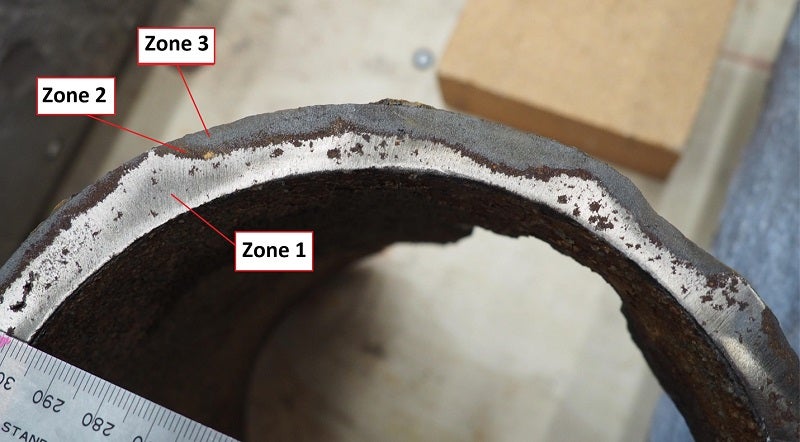

Expert inspection of defects and corrosion

Inspection is an organised examination or formal evaluation exercise. It involves the measurements, tests and gauges used for qualitative or quantitative evaluation of specific characteristics in a component or structure. The results are then compared to specified requirements in the design and relevant standards for determining if the component or structure aligns with appropriate targets.

Analytical testing (destructive and non-destructive)

At Tim Cousins Australia, various types of tests, both destructive and non-destructive, are performed and used to identify the cause of materials failure. Examples of destructive testing methods are tensile testing, hardness testing (including microhardness testing) and metallography. Examples of non-destructive testing methods are visual examination, in-situ metallography replica testing, X-ray or radiographic testing and positive material identification (PMI).

Structural integrity assessment

Structural integrity assessment helps to ensure that either a structure or structural component fits purpose under normal operating conditions or is safe when requirements exceed the original design. This includes supporting its weight and preventing deformation, breakage and catastrophic failures throughout its predicted service life.

Tim Cousins Australia starts with collecting data, including manufacturing and service histories, to provide accurate interpretation and analysis. This ensures the most effective implementation, which delivers benefits to the client.