T.D. Williamson (TDW) is one of the world’s most recognised names in pipeline equipment and services for onshore and offshore applications. TDW’s core business is to provide customers with products and services for effective and efficient pipeline maintenance and construction. TDW offers hot tapping and plugging, pressure isolation, pig-tracking and general repair and maintenance services in the following scenarios:

- Installation, repair or replacement of valves

- Replacement or repair of risers

- Bypass or decommissioning of platforms

- Tie-in of new pipelines or platforms

- Midline repair of pipelines

- Replacement or relocation of pipe sections

- Protection of assets during heavy lift and other construction activities

- Anti-flooding protection of new pipelines during pipelaying

TDW’s world-class engineering capabilities have resulted in several innovative products and services, including the tetherless, remote-controlled SmartPlug® pipeline pressure isolation tool, the SmartTrack™ system, the diverless Subsea 1200 RC hot-tapping machine and the SmartLay™ anti-flooding tool.

Pipeline hot-tapping and plugging

TDW tapping and plugging equipment is available for a wide range of pipelines and applications. Hot-tapping equipment is available for work on lines from 0.25in to 60in and at pressures of up to 99bar. STOPPLE® plugging machines have been engineered for lines between 1.25in and 56in at pressures of up to 69bar.

TDW has performed tapping and line plugging services for offshore installations and subsea projects worldwide. Standard applications include the Subsea 1000 tapping service for taps from 6in to 16in at pressures up to 152bar and at depths down to 305m.

The innovative topside-driven diverless Subsea 1200RC hot-tapping machine can be operated at depths down to 3,000m, allowing access to remote subsea pipelines where divers cannot operate. TDW has recently developed a remote-controlled Subsea clamp installation tool (CIT) for the installation of subsea clamps and related products. The CIT (comprising a TDW-supplied control skid and installation frame with running tools) can be used with any third-party work-class ROV. When used in conjunction with the CIT, the Subsea 1200RC can provide a complete solution for diverless subsea hot-tapping.

Pipeline pressure isolation services

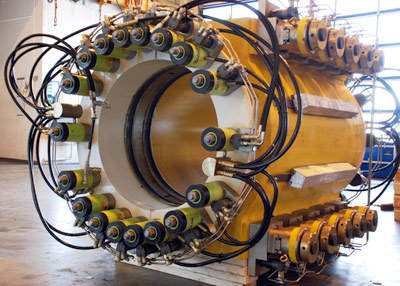

By using TDW’s proprietary tetherless, remote-controlled, bidirectionally piggable SmartPlug tool, any onshore or offshore section of a pipeline can be isolated at (or close to) operating pressure, enabling pipeline repair or maintenance works to be carried out.

This means that any assets connected downstream can continue production while the repair activities proceed. This minimises pipeline downtime and significantly reduces the environmental and economic costs associated with the otherwise inevitable pipeline depressurisation. A special configuration of the SmartPlug tool allows hydrotesting / leak testing of the repaired pipeline to be performed with the same tool.

TDW has performed more than 240 isolation jobs to date with SmartPlug tools of various configurations and sizes (8in to 48in) at isolation pressures ranging typically from 10bar to 250bar. Under certain conditions and with tools of special configurations, this range has been significantly extended from 0bar to 375bar.

The SmartPlug tool is custom-designed for each project with the exact configuration being determined on a case-to-case basis. This inherent capability of the tool to be customised for each job offers extremely flexible solutions. All tools are covered by type approval from DNV GL and isolations are carried out under the auspices of DNV GL certification to ensure compliance with all technical standards and requirements.

TDW also offers custom-designed high-friction pigs for pipeline isolation with low delta pressures or for batching / separation tasks with special safety requirements. Typical tasks include separating different pipeline contents and pipeline repair and modification projects. Due to their extremely efficient sealing capabilities, high-friction pigs can also be used for certain cleaning and dewatering applications.

Pipeline pig-tracking system

TDW’s SmartTrack system is the communications and tracking system used with the SmartPlug tool. The SmartTrack system can also be used as a freestanding application with any inline tool, such as pigs and inspection tools, for accurate tool tracking and localisation. The system offers two-way, through-wall communication based on extremely low frequency (ELF) signal technology.

The SmartTrack system has been designed with offshore subsea operations in mind, offering several advantages, such as a long battery life and the ability to track at high pigging speeds and in thick-walled or buried pipelines. Tracking can be performed by a field operator, ROV, diver, subsea antenna or a permanent receiver anywhere along the pipeline.

When running multiple tools / pigs, the SmartTrack system can immediately identify the pig that has passed. High-friction pigs fitted with SmartTrack transponders allow accurate pig-tracking, positioning, identification and continual pressure monitoring, providing an additional degree of safety.

For more information on TDW products and services, visit our website or leave an enquiry using the form below.