Atlas Copco’s Construction Technique business area provides construction and demolition tools, portable compressors, pumps and generators, lighting towers and compaction and paving equipment.

Construction Technique innovates for sustainable productivity in infrastructure, civil works, oil and gas, energy, drilling and road construction projects.

We strive for a management structure and competence that reflects the challenges and customers that we serve. This means that our global management has a good mix of people from all over the world with experience from all relevant industries.

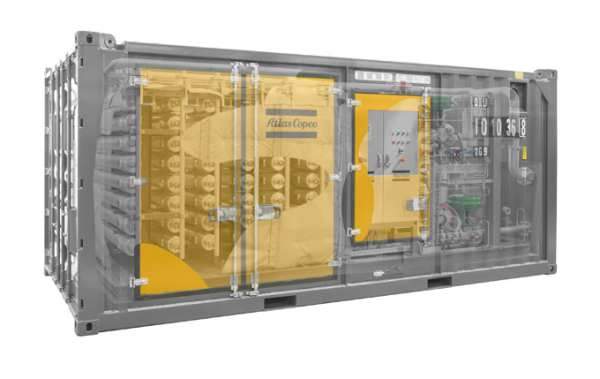

Portable nitrogen generation systems for the offshore sector

Companies working in the offshore industry require nitrogen systems for the drilling, completion and work-over of oil and gas wells, as well as onshore and offshore pipeline services.

Portable Energy offers feed-air compressors, nitrogen membrane systems and high-pressure boosters to meet individual requirements. Generating nitrogen on-site at high pressures and low oxygen levels prevents ignition of flammable gases and protects oilfield equipment against corrosion.

Compact, portable compressors for the offshore industry

The XA(T,H,V)S 146-186 Stage IIIB range comprises compact, portable compressors, designed for a wide range of applications in any condition or environment. The light weight and small dimensions make the compressor easy to manoeuvre on-site, while the user-friendly controller removes operational barriers by offering 24 language options.

The compressors are built to perform in all kinds of weather and extremely high and low temperatures of -25°C to +50°C. They can even perform in heavy-duty working environments and at high altitudes.

By combining the Atlas Copco screw element with a Deutz Diesel engine, the XA(T,H,V)S 146-186 compressors consume minimal fuel and therefore save money. The range also reduces maintenance and downtime, providing further cost-savings.

Tested in both lab and field conditions, the compressors are designed to withstand the toughest working conditions. The robust compressors guarantee failsafe and reliable operation, while the Stage IIIB Diesel engine ensures that the range complies with the latest environmental regulations.

Compressors for heavy-duty offshore applications

Hurricane compressors are small and lightweight but very powerful. Specially adapted DNV-approved containers make the Hurricane compressors ideal for heavy-duty applications, including oil and gas exploration drilling, nitrogen generation and pipeline and well services.

Air supply units and controlled oil temperature systems

The TwinAir is a robust, versatile and safety-enhanced air supply unit. It has been developed to provide the highest output and airflow for its small footprint, with a rugged design to withstand years of heavy-duty use.

The proven optimal cooler configuration, larger air intake and low airflow restriction are designed to optimise the cooling behaviour of the TwinAir. Impregnated air filters function as a fine filter to protect the engine of the compressor.

Oiltronix™ is an optional, electronically controlled oil temperature system that extends the lifetime of air-ends, compressor components, oil and the oil-separator.

FuelXpert™ is an optional electronic control module, which regulates engine speed and air inlet, in order to optimise fuel consumption for each working condition. When the air demand is lower than the output, the system ensures the right capacity for the application.

The optional intelligent air inlet system is a high-quality coalescer that protects the inside of the compressor from water, salt and sand particles.

Where possible, fixtures are made from stainless steel and special anti-corrosion inhibitors. All doors have high-specification seals with bottom drainage points. Each compressor within the container can operate independently for flexibility of operations.

About Construction Technique South East Asia

Construction Technique South East Asia has 57 employees in six customer centres: Indonesia, Thailand, Philippines, Malaysia, Singapore and Vietnam. CR South East Asia also covers Myanmar, Laos and Cambodia.

Construction Technique South East Asia is headquartered in Jakarta, Indonesia. We offer capital equipment, field support, parts inventories and auxiliary product installation. Our quality systems have an emphasis on productivity, health and the environment.

Portable Energy Division, as part of Construction Technique, focuses on portable compressors, generators, light towers and dewatering pumps.