Gencoeec alternators are of a modern design that uses the latest high quality insulating materials to withstand severe environmental conditions of heat, water and contamination. These alternators are designed for the oil and gas industry for intrinsically safe areas where dust and gases are present in extreme cases. They comply with BSS 5000 Part 16 and also IEC 60079-0 for rotating machines with type n protection, i.e. non-sparking rotating electrical machines with surface temperature limitations for hazardous areas designated Zone 2, ExnA-BIIT3, NEAMA Code Class 1 Div 2 Group D, Type n, IEC 60079-15 and EN50021. Complies with ATEXG3.

Zone 2 alternator construction

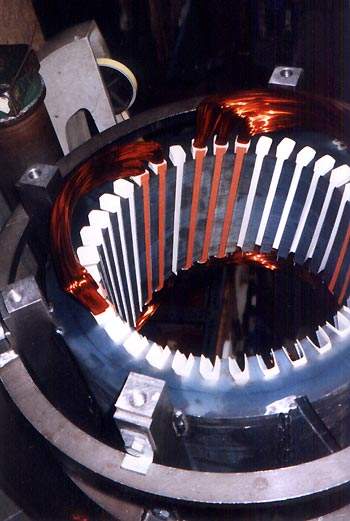

The alternators are constructed from the highest-grade materials. The stator iron is silicone-free with high residual magnetism for assured voltage build-up after long periods of standby or infrequent use. The voltage waveform is low in harmonics, with skewed slots, corded winding and graded air gaps. The internal air gap between the stator, rotor and fan clearances are sufficient to prevent static electric discharge.

The external cooling fans are made of low dielectric material. The external cooling fins are made of aluminium to ensure maximum heat transfer for the internal losses to the atmosphere. The standard working ambient temperature is 40°C, but designs can be offered up to 60°C.

The rotor construction is robust with an integral high-frequency brushless exciter, which ensures fast voltage response. Overspeed is 2,250rpm on all four-pole 50Hz to 60Hz (1,500rpm to 1,800rpm) alternators, although special machines can be offered up to 3,200rpm. All rotors are dynamically balanced. Enclosure is totally enclosed IP54-56-65 for outside use with water jet at IP65 and with two separate air circuits. Windings use class H materials allowing a 125°C rise 40°C ambient; 200°C can be tolerated for short periods.

Gencoeec machines are compliant with electromagnetic compatibility with the European Union Council Directive 89/336/EEC. Machines are total enclosed (TE), self-cooled and fan cooled (TEAB) IC41A1. Enclosures IP54-56-65.

Quality of alternators

All materials are inspected by our quality department prior to acceptance into the workshop. Internal monitoring of workshop practices and regulations is certified by independent bodies to ensure that high standards are maintained. In addition, skilled craftsmen using traditional methods ensure product quality and reliability.

Alternator outputs

- RF202/TEAB: 3-10kVA, 1 or 3 phase, 50/60Hz, 110/660V

- RF402/TEAB: 15-40kVA, 1 or 3 phase, 50/60Hz, 110/660V

- RF250/280/315/355/TEAB: 50-300kVA, 1 or 3 phase, 50/60Hz, 220/480V

A certification of conformity with full test details is provided with every machine. Inspection and a certificate by Lloyds Inspectorate of BSS5000 Part 16 – IEC 600 79-15 compliance is provided.

Brushless alternator service

Service is provided directly from our factory at Gencoeec.

Additional products

Screen protection IP21 / IP23 machines are also available in power range 5kVA to 85kVA, 50Hz / 60Hz, 1,500rpm / 1,800rpm. BS EN 60034, NEAMA MG1, IEC34.