Cabra Engineering is a specialist in engineering, design and simulation of plants, machines and industrial components (especially valves and actuators) and supports the client in every stage of product development, analysis, optimisation and technical documentation. The company also has a specialised division that provides devices and test benches for leak testing.

Industrial applications for engineering services

Cabra Engineering offers engineering activities and leak testing solutions for a wide range of industries. The company operates in various sectors in the offshore, manufacturing and transport industries, including:

- Oil and gas

- Metalwork

- Steel

- Chemical

- Aeronautic

- Aerospace

- Military

- Automotive

- Medical

- Textile

- Food industry

- Consumer goods

Engineering and simulation

Cabra performs a variety of engineering services, including:

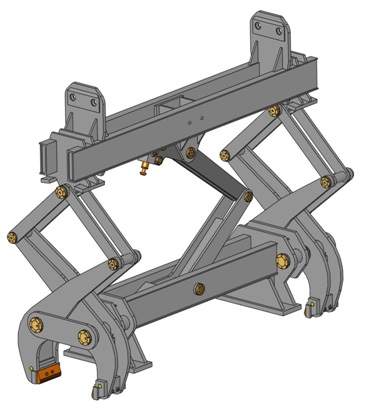

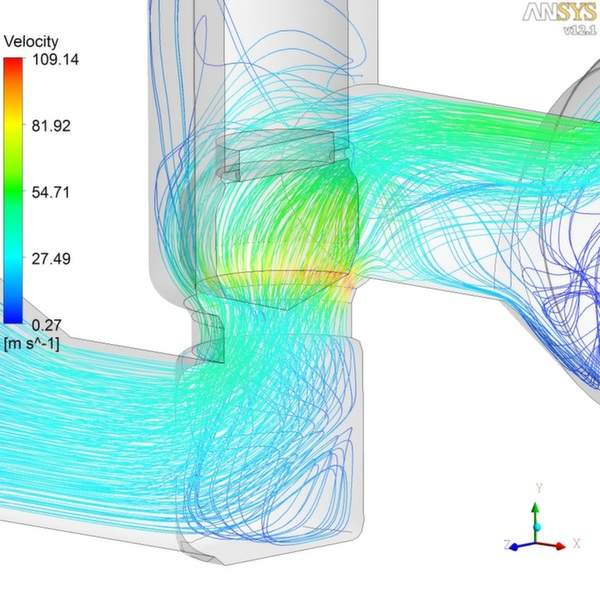

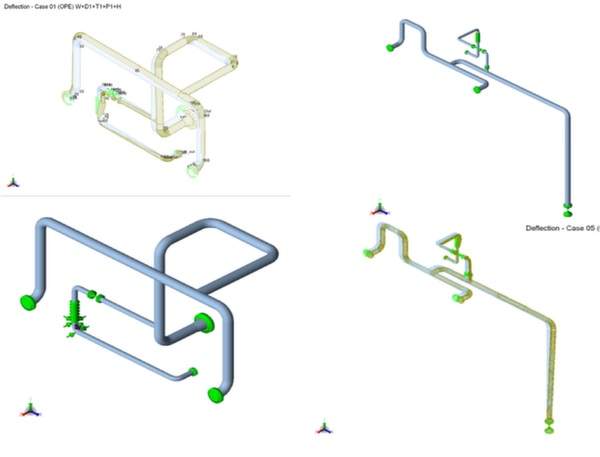

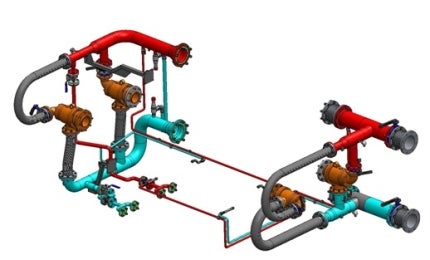

- Engineering (mechanics, electronics and software, basic engineering, detailed engineering, piping, structures ) and simulation (structural, fluid dynamics calculation (CFD), rigid body, stress analysis) of:

- Products (valves, actuators, plastic parts, etc)

- Machinery (presses, furnaces, lifting equipment / cranes, machine tools, assembly lines and packaging, special vehicles, heat exchangers, machinery for steel and aluminium industries, etc)

- Plants (chemical, petrochemical, energy)

In addition to specialised engineering services, the company supplies a range of utilities, such as:

- Outsourcing (availability to develop onsite engineering activities)

- Laboratory (performing range tests, response times, pressures of components such as valves, filters and actuators)

- Supply (prototypes, components made with application lifecycle management (ALM) technology, components made of computer numerical control (CNC), equipment and machinery)

Cabra has been gained considerable experience in solving complex problems of structural and fluid-dynamic calculation supported by an advanced IT structure with the use of a powerful server computing. The company uses the following software:

- Ansys CFX and CFDesign (thermo fluid-dynamic analysis)

- Ansys (Structural and thermal analysis)

- Caesar II (Stress analysis)

- Pro/Engineer, SolidWorks, SolidEdge, Inventor (design)

In addition, Cabra provides advisory and consultancy services on norms and directives such as machinery directive, PED, ATEX and others according to ASME and ASTM.

Leak testing solutions

A number of components and systems must be leak tested to ensure leakages are below specified limits. Cabra Engineering provides a customised solution for every leakage problems, using a variety of test methods. The system includes the optimal hardware and software to meet the client requirements.

Available solutions for leak testing include test benches and machines (turnkey supply), devices such as sniffer aid systems (SAS), as well as customised communication software for leak testing instruments.

Cabra also performs onsite leak tests on components, machinery and / or equipment for the client.

The leak testing can be provided by using the following methods of measurement:

- Micro flow rate

- Pressure drop

- Tracer gas in vacuum chamber

- Tracer gas in ventilated chamber or probe sniffer

- Tracer multi-gas, with probe multi gas sniffer

About Cabra Engineering

Cabra Engineering offers proper solutions to critical situations by proposing its customers innovative solutions, which are designed as an integral part of a full system.

The inner organisation is based on the project leader’s knowledge with a working team, formed with the necessary multidisciplinary skills required.

This dynamism enables Cabra Engineering to answer the more articulated and demanding requests coming from the market, and to integrate the skills with relevant work experiences gained through the development of engineering solutions in mechanical-industrial areas.

The company is aimed to meet the needs of the client and in realising innovative solutions matching the individual needs. Cabra Engineering has achieved UNI ISO 9001:2008 Quality and UNI EN 9100:2009 Quality in Aerospace.