Pinnacle Engineering

Construction Consulting Services for the Oil and Gas Industry

Pinnacle Engineering provides the oil and gas industry with services that include project and construction management, engineering services for structural components, production facilities, pipelines and deepwater subsea operations, as well as decommissioning solutions.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Pinnacle Engineering provides the oil and gas industry with services that include project and construction management, engineering services for structural components, production facilities, pipelines and deepwater subsea operations, as well as for decommissioning of platforms and pipelines.

The company also offers procurement services, project cost estimations, regulatory compliance engineering and inspection services.

All engineering work at Pinnacle is performed and supervised by registered professional engineers.

Structural engineering for offshore platforms

Pinnacle’s structural engineering group performs design and analysis of fixed offshore platforms and structural components.

The company prepares structure installation permit applications for submittal to BSEE, as well as providing hazard and operability (HAZOP) studies, engineering support for fabrication, loadout, transportation and installation of offshore platforms.

The engineering group performs inplace, dynamic, fatigue, pile driveability, transportation and lift analyses for offshore structures. Alongside this, the company prepares 3D models and detailed fabrication drawings for each structure using AutoCAD.

Facility design and construction management for oil and gas sites

Pinnacle’s facilities engineering group offer process, electrical, instrumentation and controls design for offshore manned and unmanned production facilities.

The facilities group prepares surface safety system permit applications for submittal to BSEE, commingling permit drawings and station bills.

Pinnacle’s facilities designers use 3D MultiSTEEL for modelling production equipment and process piping. The company’s engineers use ProMax for process modelling.

Pipeline engineering for offshore exploration

Pinnacle’s pipeline engineering group provides routing layout, hazard surveys, sizing engineering, installed cost estimates and permit applications.

It also supplies the design of the pipeline risers and subsea tie-ins, as well as coordinates the procurement of materials and installation contractors. The company prepares pipeline construction drawings and provides construction management and inspection services for installation.

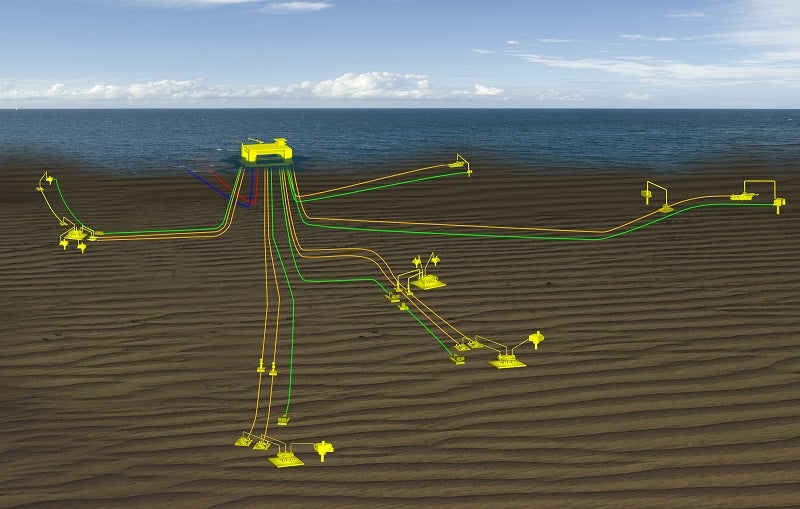

Engineering and design for subsea operations

Pinnacle’s subsea engineering group offers field planning, design, procurement, fabrication, installation, inspection, commissioning and BSEE permitting of subsea distribution and piping systems.

Designs can be created for subsea components such as umbilicals, electrical and hydraulic distribution systems, manifolds, pipeline jumpers, pipeline end terminations (PLETs), pipeline end manifolds (PLEMs), flying leads, suction pile anchoring systems, catenary risers and pipeline sleepers.

Decommissioning services for offshore operations

Pinnacle will prepare abandonment permit applications, procedures and request for quotations (RFQ). Alongside this, the company will perform pipeline abandonment project management and inspection.

For platform dismantling, the company will prepare platform removal permit applications, site clearance permit applications and platform removal RFQs. Pinnacle will coordinate the decommissioning of platform production equipment, in addition to performing construction management and inspection.

About the company

Since its establishment in 1993, Pinnacle Engineering has designed more than 300 installed platforms, including the North Sea. Pinnacle has engineered more than 250 pipelines, 100 subsea tiebacks and 150 platform removals.

Contact Details

Website

Address

Houston, TX 77063