Fornovo Gas (FG), founded in 1969, specialises in natural gas vehicle (NGV) refuelling stations, and compressed natural gas (CNG) transportation and distribution services by means of cylinder trucks and tank trucks. In addition, the company provides engineering and management consultant services in the new emerging market of CNG refuelling stations for public transportation.

Compressed natural gas technology for natural gas vehicles

With previous successful experiences in the Italian CNG market and due to significant growth in the CNG world market, in 2004, FG started the development of its own CNG compression station technology, Gasvector®.

CNG distribution is a mature industry with well established technology. FG offers all the standard products required for this industry, but with real added-value in terms of reliability and efficiency, reducing the lifecycle costs. It is FG’s mission to constantly improve design and manufacturing processes in order to improve reliability and compression efficiency to reduce LFC.

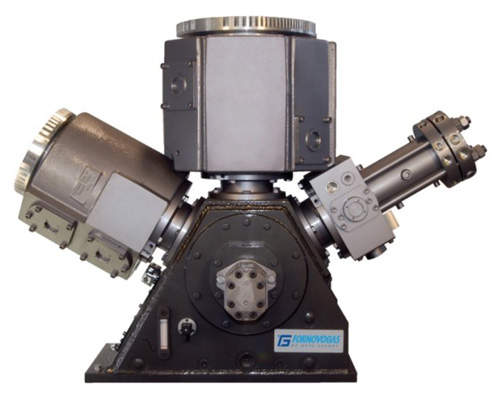

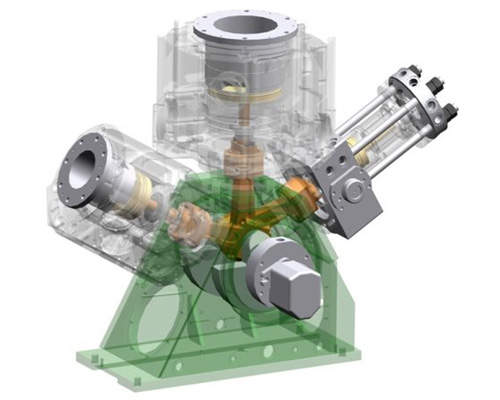

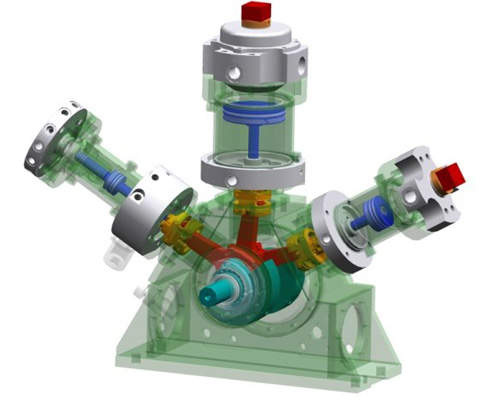

CNG compressors

FG’s compressors have been designed to meet new demands in the CNG market. The compressors are: compact, reducing weight and installation space; durable with low vibration levels and rugged design; efficient, a great number of liners and pistons bores are available for each cylinder, in order to get maximum efficiency for every specific operating condition; and flexible: new liners can be installed to adjust Fornovo Gas compressor performance to new operating conditions, minimising overall costs in the lifecycle.

Regardless of the model, all compressors have the following common features:

- Forced-feed lubrication crankcase

- Non-lubed cylinders

- Two or three cylinders, V or W-type configuration

- Cylinders for low-suction pressures, as well as for 300bar MAWP, are available

- Up to four compression stages

- Low vibration amplitudes, velocities and accelerations

- Speed range from 700rpm to 1,500rpm

- Directly driven

- Oil-free option is available

CNG compressor with double-acting cylinders

FG’s DA300 CNG compressor has double-acting cylinders, 400kW to 1,500rpm frame ratings, +/-50 kN rob load, and a 300bar MAWP.

CNG compressor with single-acting cylinders

The SA200 CNG compressor from FG has single-acting cylinders, 55kW to 1,500rpm frame ratings, +15kN / -5kN rod load, and a 300bar MAWP.

Reciprocating compressors for natural gas industrial applications

Compactness, durability, efficiency and flexibility are even more important needs in natural gas industrial applications in order to deliver efficient and high-flexibility compression services along the compressor’s lifecycle.

Our range of reciprocating compressors, from 22Kw to 400kW, can be used to package compression solutions for services including:

- Fuel gas boosting

- Gas injection and withdrawal

- Gas-gathering applications

- Pipeline transmission

- Landfill gas

- Vent gas recovery

- Air/nitrogen applications

Component manufacturing process

FG is located in the most advanced industrial district in Italy and consequently offers both manufacturing quality and purchasing advantages. FG’s manufacturing process is mainly focused on product design / improvements, supplier selections, assembly procedures and quality assurance.

FG has adopted a new ERP information system to control the manufacturing and supply chain management processes in 2008. All other modules will be implemented during the second quarter in 2009.

Compressor quality system

FG’s quality system has been certified by DNV according to ISO 9001:2000 since 2002. Qualified mechanical engineers are locally available to support production peak without risking the product quality. Amongst others, FG uses the following main design instruments:

- 2D and 3D CAD

- Time-domain simulation SW

- FEA analysis SW

- Performance modelling tool

Each machine is fully tested in FG’s test bench under real operating conditions. For instance, grid natural gas is available in Fornovo Gas workshop at a wide pressure range.

CNG innovative technology

FG’s technology can support a range of industrial applications efficiently. The company is committed to developing its capabilities as a solution provider and is constantly investing in technology improvements and process optimization. FG’s successful growth is based on a combination of state-of-the-art technology, reliable products and value-added customer services.