Hammelmann has been manufacturing plunger pumps for industrial applications for almost 60 years. In the past 20 years, Hammelmann has developed a range of pumps specifically for the oil and gas industry, in particular, the offshore sector.

Whether they be high-pressure chemical injection pumps, water injection pumps, hydraulic power unit pumps or ultra high-pressure surface preparation pumps for plant maintenance, Hammelmann and OEM packages can be found on hundreds of oil exploration and production facilities worldwide, including a number of FPSOs.

High-performance pumps for the offshore oil and gas industry

Our pumps are available in the following performance ranges:

- Operating pressures of 55bar to 3,800bar (800psi to 55,000psi)

- Flow rates of 0.2l/min to 2,000l/min (0.05gpm to 530gpm)

We precision machine parts from a wide range of high-grade materials to suit the various pumped mediums. These include:

- 316 stainless steel

- Duplex and Super Duplex

- Hastelloy®

- Inconel®

- Titanium

The design and manufacture of our pumps is carried out in accordance with international standards and recommendations, including API 674, NACE MR 175, ATEX and NORSOK.

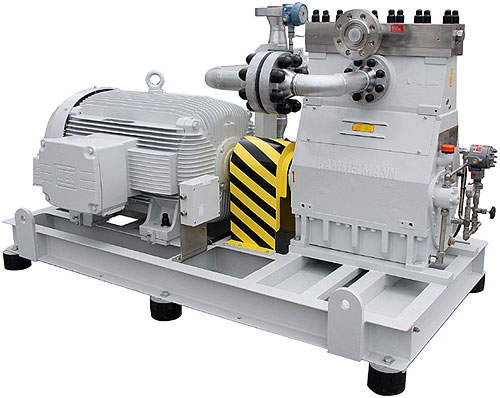

Hydraulic power unit (HPU) pumps

There are over 300 offshore installations employing Hammelmann high-pressure pumps to pressurise the hydraulic units necessary to operate and control many of the special underwater systems, etc.

Our pumps can handle all hydraulic fluids, including mineral oils, glycol, water-based oils, low-viscosity oils, water oil emulsions and amines.

They provide high performance from a small footprint resulting in very compact HPUs that make the most of the often limited space.

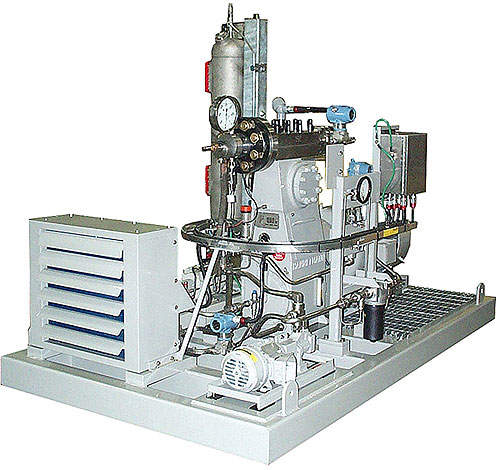

Hydrate inhibitor injection pumps

Hydrate build-up is a problem for both topside and down-hole operations. A range of Hammelmann pumps employing a metal-to-metal labyrinth sealing system is ideal for injecting hydrate inhibitors such as methanol, ethanol, glycol and low-dose hydrate inhibitor (LDHI) into the production lines of oil and gas reservoirs.

The labyrinth seal sets new standards in safety and reliability for pumping operations on offshore platforms and has become the seal design of choice for injection applications in excess of 700bar. The unique design of the seal system eliminates the possibility of the pressurised pumped medium emitting the pump accidentally.

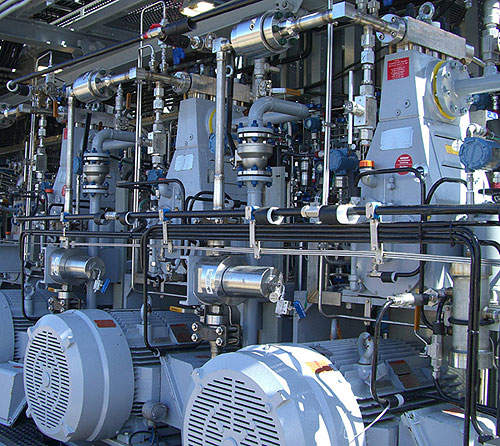

Produced water and seawater injection pumps

Hammelmann plunger pumps are used in the secondary oil and gas extraction process to inject pressurised produced water back into the reservoir. Seawater is also used for this process.

The pumps have bellows seals between the plungers and drive end that hermetically seal to atmosphere and prevent impurities and salt-laden fluids entering the drive end.

The use of highly corrosion-resistant materials such as Duplex stainless steel, Hastelloy®, Inconel® and the like means that Hammelmann pumps can be deployed in practically all situations.

Chemical injection (dosing) pumps

Hammelmann high-pressure pumps are built into extremely compact units for accurately dosing asphaltene, corrosion, paraffin and scale inhibitors.

With the variable speed drive it is possible over a range of 1:10 to dose a minimum volume of 0.2l/min (0.05 US GPM) at an operating pressure of up to 3,000bar (44,000psi).

The ‘zero emission’ design ensures that the pumped medium is completely sealed within the pump ensuring safe operation and enabling the dosing of environmentally dangerous, toxic and explosive mediums.

Other pump products for the offshore industry

Hammelmann also offers bullheading pumps, condensate pumps, flare knock-out drum pumps, MEG pumps, TEG pumps, industrial cleaning pumps, systems and accessories, and UHP surface preparation pumps.