MZT Pumpi has been dedicated to manufacturing industrial pumps for transporting water, oil and oil derivate for more than 67 years. The key element to survive in this dynamic industry is flexibility in pump design, and offering integrated solutions to client requirements. The company’s product range of different centrifugal and rotary pumps is constantly under development, with an ultimate objective to satisfy ever-changing client demands.

Pumps, pump aggregates and complete pump systems

MZT Pumpi supplies individual pumps, pump aggregates and complete pump systems. Apart from the manufacturing of pumps, the company is highly engaged in projects concerning the erection of pump stations, such as revitalisation and rehabilitation of existing wastewater treatment plants; and pump stations.

Typical applications of the MZT Pumpi product range include:

- Water supply and irrigation

- Process industry

- Chemical industry

- Oil and gas

- Mining and civil engineering

- Special environments where we design pumps to meet specific client needs

MZT Pumpi has a head office in Skopje, Macedonia, where it employs a staff of 130 for maximum customer satisfaction and high levels of quality, short delivery times and competitive prices.

End suction centrifugal pumps

MZT Pumpi manufactures single stage, low pressure, centrifugal end suction pumps with an axial inlet into the impeller and vertical outlet flange, with flanged bearing frame, developed according to ISO 2858 standard. This range of pumps has a capacity of up to 2,500m³ an hour, operating pressure up to 25bar and come in 40 different sizes. They are available in horizontal and vertical design.

High-capacity split case double suction pumps

Horizontal split case double suction centrifugal pumps are engineered to pump clean water or low viscosity clean liquids at moderate heads more economically than any other type of pump. Their maximum capacity is 10,000m³ an hour, and head up to 14bars.

Their typical application is for liquid transfer and circulation of cold clean or slightly polluted water. They are available in horizontal and vertical execution.

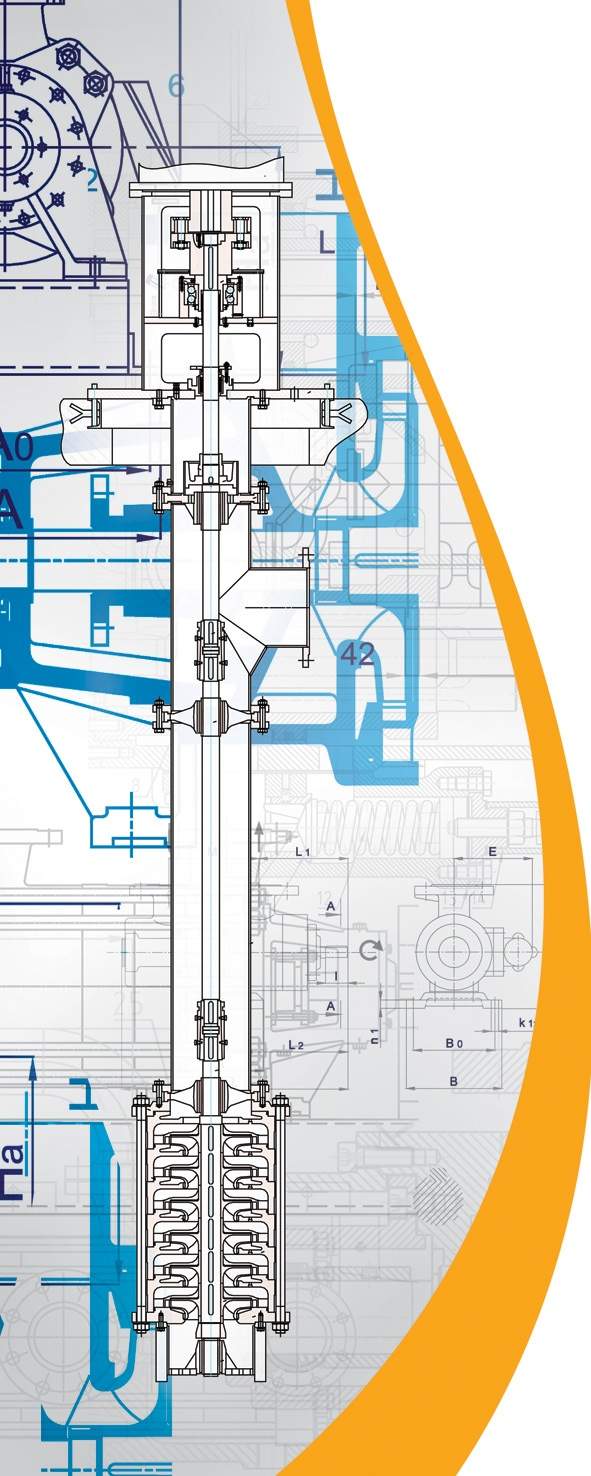

Vertical turbine deep well pumps

This vertical turbine semi-axial pump converses the capacity range up to 2,160m³ an hour against head of up to 210m, one or several stages.

Main advantages include:

- Non-submersible electric motor, so no need for sealing and a longer pump lifecycle

- Self-lubricating intermediate bearings

High-pressure multistage centrifugal pumps

MZT Pumpi manufacturers multistage pumps in two series: MS type for higher capacity (864m³ an hour) and lower pressure (up to 37 bars), and KCP design for lower capacity (306m³ an hour) and higher pressure (65 bars). Both categories can be manufactured both in horizontal and vertical execution, and with a cooling system.

Typical applications of MS pumps are: water circulation, irrigation and drainage, mining and civil engineering, industrial and process services, transport of thin oils, chemical and process industry.

Typical applications of KCP pumps are: agriculture irrigation, boiler feed, chemical industry, coating and surface treatment, paper mills, pressure boosting systems, lube and seal oil supply for rotating equipment.

Self-priming multistage centrifugal petrol transfer pumps

BCP petrol pumps are centrifugal, self-priming, multistage horizontal pumps, with capacity up to 180m³ an hour and head up to 20bars. They are assigned for transport of all kinds of petrol products, ammonia, benzol, etc. BCP pumps are designed as single stage and multistage.

The main advantage of BCP pumps is that they are equipped with a cavity impeller and relief valve for protection of the pipeline from high pressure.

Main fields of application include:

- Loading and discharging of tankers and lorry tanks

- Refinery process pump

- Petrol storage tanks

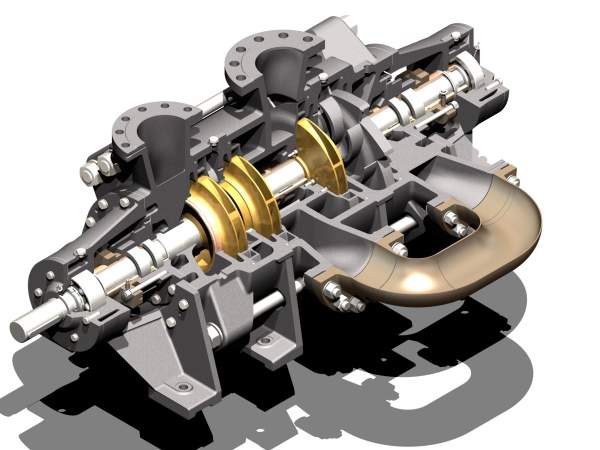

Volumetric three screw spindle pumps for viscosity

The main working elements of the pump are three screw (helical) spindles (with special profile) and screw casing. Working spindles are totally hydraulically disburdened of axial forces. Fluid is moving axially without turbulence and mixing which enables pumping of a lot of viscous fluids without making foam.

The capacity of these pumps is up to 252m³ an hour, with a pressure of up to 80 bars and viscosity up to 800Cst.

Three-spindle screw pumps are used to transport viscous fluids with lubricating properties: lube oils, fuel oils, synthetic, mineral and vegetable oils.

Typical applications are:

- As transport pumps for loading and unloading of tanks and tankers

- For lubricating of machines, engines, turbines generators

- For dosing of fuel oil in burners

- For transport of viscous fluids for other applications

Macedonian pumps with proven quality

MZT Pumpi pumps are manufactured according to the following management and product international standards:

- Quality management system ISO 9001:2008 certified by BSI

- CE, Atex, ISO, EN, DIN, GOST TR

- Environmental quality management system ISO 14001:2005 certified by TÜV

- Occupational health and safety management system OHSAS 18001:2007 certified by TÜV