atg UV Technology are the worlds’ only UV manufacturer to specialise in ultraviolet (UV) treatment systems and integrated technology packages for the oil and gas industry. atg UV Technology has more than 30 years’ experience across a range of offshore and oil and gas applications, including:

- Potable drinking water disinfection

- Well-injection and seawater treatment, including sulphate-reducing bacteria (SRB) reduction

- Produced water treatment (reinjection & discharge)

- Flowback water treatment (reinjection & discharge) for unconventional oil and gas – hydraulic fracturing

- Pipeline flooding and hydro-testing water

- Blowout preventer (BOP) hydraulic control fluid treatment

atg UV Technology have delivered hundreds of UV systems and packages to the oil and gas sector. As the worlds’ leading provider of offshore UV equipment, atg UV’s engineering capabilities can fully meet the most demanding of offshore operator specifications, including:

- ATEX / IECEX Designs / Zones 1 and 2 / Ex-D, Ex-E, Ex-IA and Ex-P solutions

- Skid packages & containerised solutions

- Client Specifications: Electrical, mechanical, design loads, documentation

- Multi-technology packages: Filters, pumps and dosing

- Pressure vessel designs: ASME VIII Div 1, PD5500, EN13445

- Winterization and tropicalisation Exotic materials: duplex, super duplex, copper nickel and titanium

- Specialist designs: NORSOK, NiPH, GOST, DOSH, NSF, US EPA UVDGM

Standard offshore UV applications

Offshore potable drinking water disinfection

atg UV Technology is the worlds’ leading supplier of oil & gas UV drinking water disinfection systems, used to sterilise crew water supplies offshore.

UV is now the disinfection technology of choice offshore, providing a simple, chemical-free solution that protects against all known bacteria, including chlorine-resistant microorganisms such as cryptosporidium and Giardia.

atg UV Technology UV systems fully meet the guidelines for offshore potable drinking water set by the World Health Organization (WHO), providing a >4 log reduction (99.99%) of harmful micro-organisms in a single pass.

Selected UV models are fully certified to meet the requirements of NSF-55 (Class 1 and Class 2) and NiPH (FHI Water Report 120) certified offshore potable water installations.

BOP hydraulic operation fluids

atg UV Technology performed the original research and pilot trials into treating hydraulic operation fluids used to control subsea BOP systems with UV light in order to successfully prevent bacterial growth.

B.O.P. units are critical safety devices that prevent the uncontrolled flow of liquids and gases during drilling operations.

They are typically controlled and operated by hydraulic fluids comprising potable grade freshwater, a glycol-based anti-freeze and soluble lubricants with corrosion inhibitors.

If left untreated, the levels of bacteria present in the hydraulic fluid can quickly begin to rise, leading to a range of negative consequences such as microbial corrosion and the formation of particles in the fluid.

These can lead to critical BOP failure and unrepairable damage of the Blow Out Preventer itself. atg UV Technology are the only manufacturer in the world to offer a fully tested and field proven BOP control fluid UV treatment package, and have supplied a number of ATEX certified, UV + filtration packages to leading oil and gas drilling contractors worldwide.

Well injection and produced water disinfection

For more than 30 years, atg UV Technology has successfully used UV to control microorganisms such as SRBs, acid-producing bacteria and slime-forming bacteria, in well stimulation and injection applications.

In a collaboration with Conoco Phillips, atg UV Technology researched the effectiveness of UV treatment for SRB reduction used in well injection applications in 1993.

This led to the supply of a number of offshore UV treatment plants being installed in the Norwegian North Sea sector, with the Eldfisk and Ekofisk plants treating 4,500m³/h and 4,000m³/h a day.

Advanced oxidation for produced water

atg UV Technology has recently patented a unique ‘chemical-free’ advanced oxidation process, known as Keratox, for treatment and removal of organic and chemical contaminants from produced water before environmental discharge or re-injection.

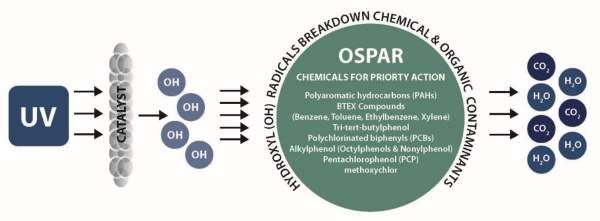

Using a unique titanium dioxide (TiO2) catalyst to create Hydroxyl Radicals, the Keratox Advanced Oxidation Solution (AOP) can be used as a final polishing technique to remove contaminants detailed on the OSPAR list of ‘chemicals for priority action’ such as polyaromatic hydrocarbons, BTEX compounds and phenols.

UV disinfection of pipeline flooding water

Chemical biocides such as glutaraldehyde and THPS have traditionally been used to prevent bacterial growth, however strict limitations on discharges to the environment have seen operators look for new innovative water treatment solutions that have zero environmental impact.

UV disinfection has been proven as an effective alternative technique to chemical biocides, particularly against SRB’s, slime forming bacteria and acid producing bacteria.

atg UV Technology can offer equipment treating 1m³/h to 6,000 m³/h in single 20ft container, and have supplied some of the worlds’ leading operators with both equipment sale and rental solutions.

This includes the worlds’ largest pipeline project, the Nord Stream Pipeline in the Baltic Sea that treated 3,000m³/h of sea water and achieved a 99.9% reduction of SRB’s in a single pass through the UV system.

Benefits of UV water disinfection

atg UV Technology’s water disinfection systems comprise a single pass treatment; no overdosing of the water is possible and no subsequent chemical removal is requiredUV light is a chemical-free, green disinfection solution.

Unlike traditional chemical methods, no organism has demonstrated any immunity to UV disinfection and the use of biocides can be dramatically reduced.

Volume reductions of biocides up to 90% have been demonstrated during field usage with atg UV Technology systems.Disinfection performance is supported by the use of independent third-party validation (type approval using bioassay testing) and computational fluid dynamics (CFD) analysis.