BEA Technologies is a global leader in the design and manufacture of specific filters and automatic filtration systems for the treatment of liquids and compressed gases in oil and gas plants, offshore platforms and FPSOs. It is an ISO 9001:2008 certified manufacturer of filter cartridges, equipment and systems. The company’s network of local agents and distributors provides the company with a comprehensive extended presence to serve customers globally.

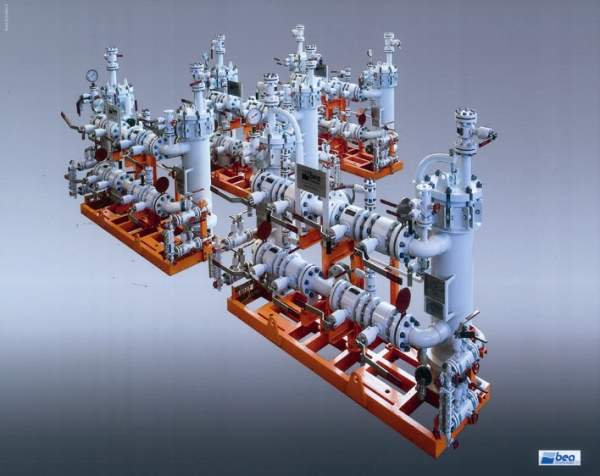

Filtration for offshore installations and FPSOs

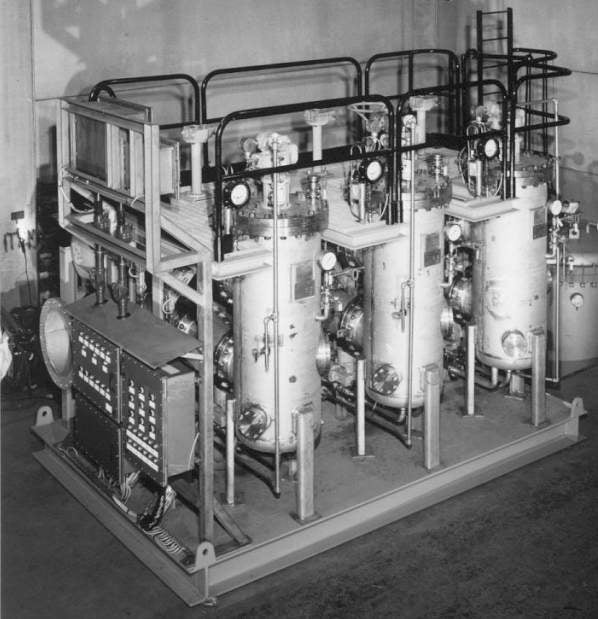

With 50-plus years of experience in the filtration market, BEA Technologies leverages its engineering background to optimise the filtration process and satisfy the needs of its customers.

The BEA range of filters includes:

- Automatic backwashing filters for seawater and cooling water

- Filters for drilling operations and completion fluids

- Water injection filters and units.

- Coalescer packs and cartridges to separate water from natural gas

- Compressed gas filters (nitrogen, hydrogen, carbon dioxide, fuel gas, diesel oil) and utilities for field development

- Filters for water to clean and check the integrity of piping and pipelines

- High-pressure filters for the injection of chemicals

Microfiltration

BEA Technologies manufactures filter elements dedicated to microfiltration in clean rooms rated from class 100,000 down to class 100, in compliance with GMP guidelines for high critical applications. The company conducts non-destructive integrity tests on all membrane filter cartridges that are manufactured for sensitive applications that require absolute bacterial retention. It also has the in-house capability to test filters for performance efficiency by laser particle counters, to conduct bacterial challenge testing and to integrity test with a range of methods.

Filter elements are provided with:

- PES and nylon membranes for liquid filtration

- PTFE membranes for air and gas filtration

- Filter elements made with borosilicate fibres to retain colloidal particles

- Cartridges made of pleated multiple polypropylene or polyester layers

- High surface elements up to 10m² to filter highly contaminated fluids

- Mini-cartridges and flat membranes for laboratory service

- Pleated regenerable metal filters for high-pressure or high-temperature applications

Treatment of compressed air and gas

Compressed air and gas filters include:

- Fuel gas filters for gas turbines

- Coalescer filters to separate oil and water and light condensate hydrocarbons droplets from the main gas stream

- Filter separators to protect gas compressor stations

- Filters for vacuum pumps

- Oxygen, hydrogen and nitrogen filters

- Filters for the protection of sensitive instrumentation

- Activated carbon filters to retain acid particles and adsorb acid off-gas

- Coalescer filters and particulate filters for gas dehydration unit protection

Industrial filters and processes

Process filters equipment and packages include:

- DUOMATIC: automatic filtration systems for hydrocarbons feedstock

- FILTROMATIC: automatic backwashing filters for water and seawater

- PROMATIC: automatic filtration systems with backwash gas assistance for heavy and dirty hydrocarbon feedstock and biodiesel oil clarification

- Filters to regenerate washing water

- Amine purification systems

- Activated carbon filters to retain acid organic sub-products

- Coalescer filters for hydrocarbon fuels to separate residual water

- Systems for high-pressure and temperature gases

BEA Technologies company profile

BEA Technologies is able to provide its series of innovative filters due to its investments in research and development and the continuous growth of its design and technical capacity. It remains focused on making the highest-quality products and providing personnel for better customer service and a more effective business approach. The company’s mission is to deliver the industry’s most innovative filtration products that generate strong operating results and savings for customers.