Costacurta S.p.A.-VICO is an Italian company specialised in separation technologies. Costacurta offers a wide array of products, solutions and engineering services in the fields of oil and gas production, refining, petrochemical, power generation and desalination.

Separator internals

Costacurta’s gas-liquid separators are generally used to remove droplets carried by vapour streams in order to reduce the loss of expensive products, increase product purity, prevent the corrosion of downstream equipment and reduce pollution of vapour waste into the atmosphere. VICO-Tex®, VICO-Vane, VICO-Chevron, VICO-BSA and VICO-Spin are widely used in different sectors including environmental protection, oil, petrochemical and chemical industries.

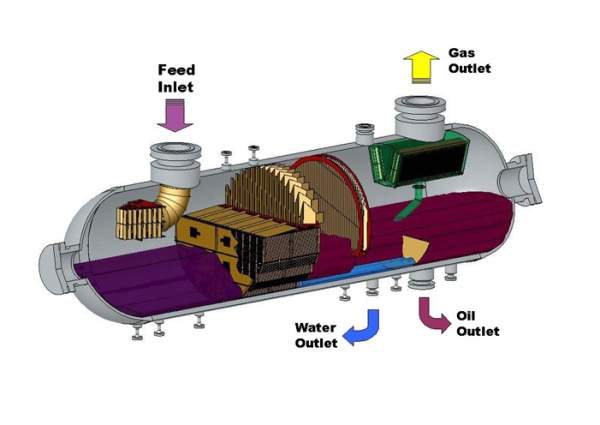

Costacurta’s liquid-liquid separators can be installed in both horizontal and vertical vessels. These products increase the separation efficiency of two liquid phases that cannot mix by reducing the loss of expensive constituents, increasing purity, preventing equipment corrosion and controlling pollution. VICO-Pack sloped plate coalescers and VICO-Tex® coalescers are core Costacurta liquid-liquid separators. These components have reached sizeable results not only on offshore platforms but also in post-extraction treatment of natural gas and oil.

Gas-liquid distributors, such as vane feed inlet distributors, are installed on feed inlet nozzles in vessels (horizontal or vertical) and distillation columns. These allow a uniform distribution of gas in the inlet area and promote a primary separation of the liquid present in the gas. Flow equalisers such as Costacurta’s VICO-straightener are normally installed in vessels to uniformly distribute vapour stream, break waves and avoid the formation of foam. The result of this is a pre-separation of larger droplets and an increase in overall separation efficiency.

Custom separation solutions

Costacurta can design and manufacture separator internals on demand, specifically designed to meet performance requirements at given operating conditions. These tailor-made solutions offer both process and mechanical guarantees.

Main activities carried out include data collection, determination of process conditions upstream and downstream of separators, vessel dimensioning, selection and design of internals, positioning of process nozzles, liquid level setting, sketches and mechanical design. Proprietary process design software, CFD and FEM analyses are used to guarantee the desired performances. Installation supervision and start up assistance are additional services that Costacurta can provide its customers.

Engineering services: design, optimisation, debottlenecking and troubleshooting

Costacurta’s engineering team is equipped to provide a wide range of services to its clients.

Design consists in the evaluation and recommendation of separation solutions for new installations. A detailed feasibility study providing vessel dimensions, size and position of nozzles, layout of internals, separation performances and cost estimates is delivered to the client.

Optimisation and debottlenecking consist in operation assessments for improvements of separation performances on existing installations. A comprehensive feasibility study providing layout of internals (including additional separators if deemed necessary), additional fixing systems, separation performances and cost estimates is delivered to the client.

Troubleshooting consists in operation assessments for detecting causes of separators malfunctioning. A complete troubleshooting report highlighting causes, recommended remedies and estimated costs is delivered to the client.

Computational fluid dynamics (CFD)

Ordinary process design assumes laminar flow, which is rare in real life situations. CFD uses algorithms and formulas to analyse a fluid’s flow. Specialised engineers undertake CFD simulations to examine what happens during separation of different fluid phases in a vessel.

This translates into meticulous process design which guarantees reliability and increased efficiency. Floating production, storage and offloading (FPSO) is just one example of the many applications where this software can generate considerable benefits.

Research and development

Costacurta has been collaborating over the years with Italian universities to have an edge on theoretical and calculation aspects that are critical to separation technology. Costacurta’s testing unit enables product performance assessment. Results can be gathered both by test witnessing and by the use of instruments that provide meaningful data, which our engineering team can then analyse.

These tools demonstrate commitment to stay on top of separation technologies and enable Costacurta to develop its own products as well as undertake joint development activities with key clients willing to test their ideas and exchange views with top tier engineers specialised in the field of separation.

92 years of experience

Costacurta’s 92 years in business guarantees reliability, precision and commitment towards the client. Our team of engineers and specialists can offer excellent solutions to a wide variety of separation problems in numerous sectors. Costacurta products and services will enhance the separation efficiency of your production unit.