With years of experience in the oil cleaning and maintenance sector, Europafilter’s knowledge is second to none. The company’s effective EF2000 & EF2100 series has been specifically designed to increase oil lifespan and cleanliness. After years of installation and result comparison, our catalogues of oil analysis results prove that our product does exactly what we claim it does.

Our aim is to keep the environment clean with less oil waste, and to keep your processes clean. As a result of this, you can increase your equipment reliability, allowing you to make more money and save more money at the same time. Together with unrivalled support, service and communication from us, we are certain you will see the benefits of preventative rather than reactive maintenance.

Cleaner oil for a cleaner environment

Disposing of waste oil is costly and damaging; any product that reduces this is beneficial. Suppose that product actually cleans the inside of your machine, removing water, salts, varnish and other particles. Europafilter does exactly this.

In some cases, the oil in the machine (once filtered) is cleaner than new oil. Oil does not degrade; it oxidises or traps particles, and consistently clean oil will never require a change.

Oil filters for particle removal

Since 70% of damaging particles in oil are less than 1µm, it is important that these particles are removed for oil to be reused. Tests have proven that Europafilter removes particles down to 0.1µm. The filter insert EF500HY can hold up to 3kg of waste, while many other filters can only hold a few grams of waste. This again is another positive impact on the environment.

Minimised downtime and costs

How much does it cost to take a machine out of service? The cost of new oil, disposal of old oil, labour and parts could run into tens of thousands. Whilst we are unable to entirely remove the risk of breakdown, we can significantly reduce it simply by cleaning the oil. Once oil is cleaned it acts as a cleaner itself, constantly cleaning the internal components of your equipment.

Independent oil analysis

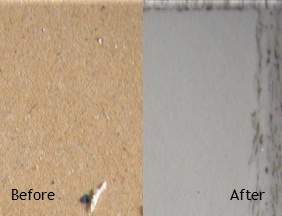

Europafilter will take an oil sample before the installation. This is sent to an independent oil laboratory to examine the oil and determine its state. We have seen results where oil is classed in the advanced warning stages.

After the Europafilter is installed, and the oil has cycled through the filtration system, a further sample is taken. Results show that the oil condition has improved, and continues to improve.

About Europafilter

Europafilter has been developed by Aegir Bjornsson, an Icelandic Naval captain. The first sector to discover the benefits was the fishing industry, and companies in the oil and gas industry. Companies such as Associated British Ports, Maersk, Statoil, Stenna Drilling, Scania and Volvo all use Europafilter. We have sample oil analysis results and reviews of our product for your reference.

Please contact us using the forms below to request more information or sample oil analysis results. One of our experienced team will be able to discuss your requirements and installation. We are certain that our test results speak for themselves, and urge you to view them.