Stopdrop Tooling provides hand tools that have been designed to prevent dropping when working at heights. Tooling kits from Stopdrop Tooling are suitable for the toughest environments and industries such as oil and gas, chemicals, petrochemicals, construction, mining and utilities.

At Stopdrop Tooling, we continue to develop and evolve new kits aimed at specialised trades within various industries.

Offshore tooling kits and modifications

Stopdrop Tooling has established customers worldwide, working in close consultation with experienced HSE and maintenance managers for various drilling contractors to provide industry-specific tooling and modifications. Stopdrop is a member of the Drops Workplace Organisation, which is dedicated to reducing drop incidents in the oil and gas industry, on and offshore.

Hand tooling kit lanyard attachment protection system

All Stopdrop benchmark-quality tools are supplied with the Stopdrop protection system lanyard attachment point. By properly securing hand tools to a fixed point or person with a lanyard and using locking techniques for individual tool parts, dropped objects incidents can be prevented. Lanyard attachments are sized to the tool to ensure the correct attachment is used by the operator.

Tooling system with safety control

Stopdrop’s tooling systems are modified to enable user freedom / product functionality but continue to safely control the tool. Lanyard attachment points are located to enable control of turning and gripping when using screwdrivers and pliers.

All socket retention ratchets and power handles have a two-point locking control, one on the body of the tools for lanyards, the other in the positive-lock mechanism, which holds all socketry in a fixed-lock position, including extensions and step-up adaptors. Sockets have a hole drilled to ensure positive lock when used on ratchets or power handles.

The Stopdrop system is flexible and varying customer options are available, including colour coding, laser engraving and tool kit building.

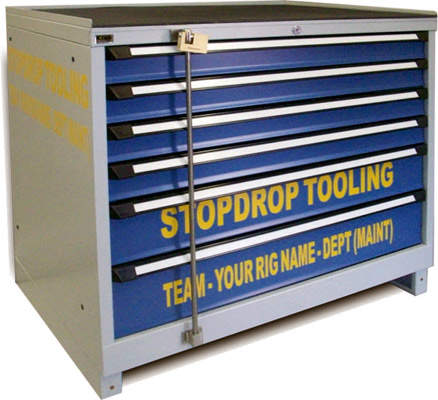

Standard derrick maintenance kit

Stopdrop’s standard derrick maintenance kit consists of 168 tools and accessories for working at height. The derrick maintenance kit is in use on offshore facilities worldwide. It has six drawers, each with 100% extension, 100kg capacity (only one drawer can open at a time), is fitted with roller bearings, and has central locking and anti-tilt mechanism combined with a floor plinth (rather than wheels), providing an excellent and safe hard-wearing and durable storage cabinet.

Tooling is stored in the Plastizote Tool control foam, which provides a quick visual inventory control. Each tool has its own profiled space ensuring tools are returned to the box and not left at height.

Colour sleeving visually identifies tooling as Stopdrop and prevents migration between individual kits. All tools provided by Stopdrop Tooling are laser engraved with your choice of identifier. The difficult-to-remove markings provide additional confirmation of the kit storage location.

Portable at-height kits

Stopdrop supplies portable at-height kits to individual specifications. Supplied in hard-wearing Peli tool cases of various sizes, tools are stored in foamed layers allowing the whole space to be utilised with the correct tool requirements and still give the visual aid of the tool control.

All Stopdrop products are available individually in any quantity you require.

Reducing dropped-object incidents

Hand tools are one of the most common sources of dropped-object incidents. A dropped-object incident can cause serious harm to people, damage equipment, cause downtime and result in reputation damage to a company. At Stopdrop, we are continually developing new products and concepts. If you aspire towards 'zero drops', Stopdrop Tooling provides the answer.