BHDT – Excellence in High Pressure

BHDT is the market-leading manufacturer of medium and high-pressure piping, prefabricated isometrics, valves and fittings for the LDPE/EVA and UREA sector worldwide. We also manufacture equipment for the Offshore Technology market.

Based on profound knowledge in material science and decades of experience in producing medium and high-pressure equipment for petrochemical and fertilizer production, BHDT has established long-term business cooperation with all major process licensors.

Our knowledge of process technologies, our state-of-the-art product design, quality, and excellent after-sales service guarantee the optimum functionality and the long service life of our products. We also provide on-site installation, start-up, maintenance, and welding service.

Medium and high-pressure equipment manufactured by BHDT is exclusively tailor-made in order to fulfil the requirements of our customers in the best possible way.

BHDT high-performance components

- Piping: medium/high/extra high-pressure piping | prefabricated isometrics

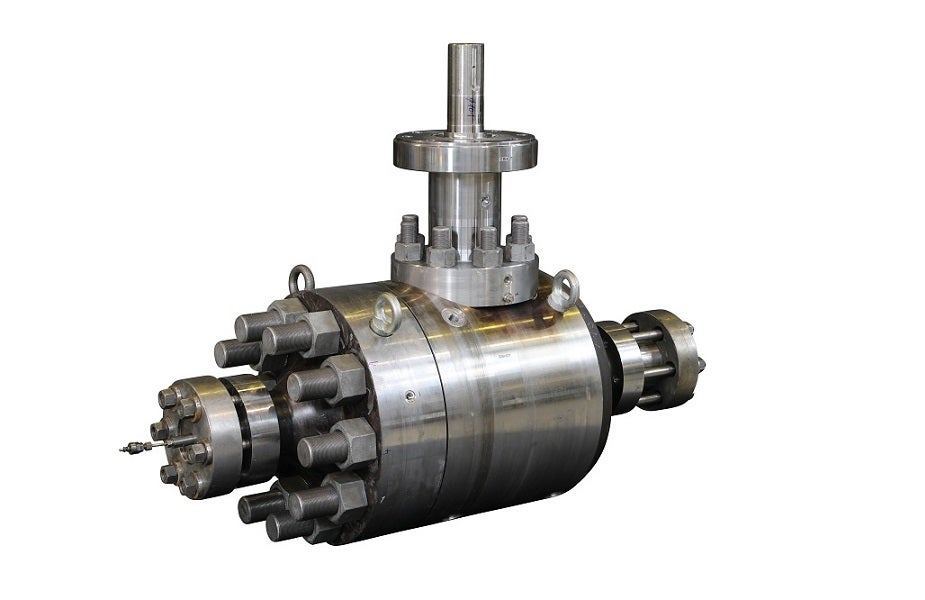

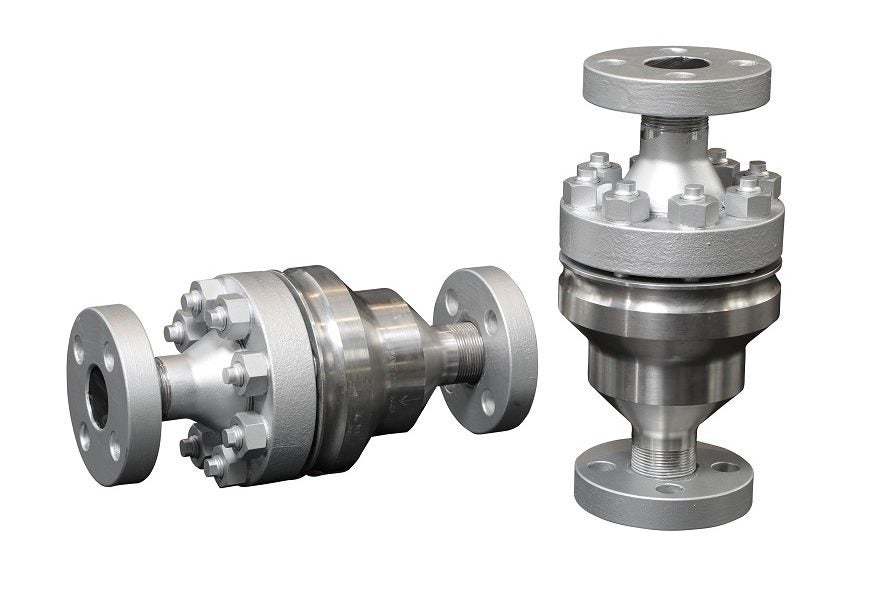

- Valves: manual/actuated/control/safety/check/sampling valves

- Fittings: flanges | lens rings | elbows | distribution blocks | T-pieces/blocks | reducers | weldolets | rupture discs | special items

- Connectors: BestLoc® Clamp Connector | BestLoc® Compact Flange (ASME) | BestLoc® Compact Flange (Norsok L-0005)

- Accessories: Hydraulic oil units | valve test stations | bolt torqueing equipment | bolting material

About BHDT

Established in Austria in 1958, BHDT is a manufacturer of medium and high-pressure equipment such as valves, piping systems and connectors for special applications in the oil and gas, petrochemical and energy industries.

We also offer on-site installation, start-up and maintenance services.