ANT is the world’s market leader in manufacturing specialised equipment for well servicing operations and for cutting and dismantling tasks within the offshore industry. The company supplies the proprietary Water Abrasive Suspension (WAS) jet cutting equipment and cutting devices such as cutting tables and manipulation systems.

We demolish and repair casings, pipelines and steel structures in air and underwater, including areas where there is a risk of explosion. ANT systems are particularly suited for the environmentally friendly disposal of oil and gas platforms without the use of divers. Our cutting units are also the perfect equipment for internal cutting tasks in narrow pipes (from 40mm) up to depths of 600m using ROVs, remotely operated manipulators and robots with remotely operated cutting heads.

WATER ABRASIVE SUSPENSION (WAS) JET CUTTING

With the Water Abrasive Suspension (WAS) cutting process almost all materials can be cut with the aid of a high pressure water jet and sharp-edged abrasive. The cuts are executed in a contact-free manner, with no significant heat generation or deformation, regardless of the material in question. They can also be performed using contact-free remote manipulation systems for bridging large distances of up to 2,000m between people and the cutting zone by means of mobile cutting tables on guide rails and ROVs.

The particular know-how that we have developed is located in the valve technology and in the mixing of water and abrasive material at high pressure. The important parts of the equipment include a high pressure pump, a mixing unit for the abrasive material, high pressure hoses and a cutting nozzle of 0.5mm to 1.3mm diameter. Suitable for cutting tasks in both air and under water, ANT’s offshore Water Abrasive Suspension (WAS) technology combines high cutting velocity with high accuracy.

WAS technology provides only one hose to the cutting nozzle and operates to a minimal cutting seam width of less than 1mm (low secondary waste). Designed to create dust- and gas-free cuts, WAS cutting requires minimal consumption of abrasive material and features effective remote manipulation capability.

WAS FOR OFFSHORE APPLICATIONS

The offshore industry has discovered the WAS cold cutting method as an irreplaceable tool for the cost-saving accomplishment of all jobs that have to be executed as fast and safe as possible.

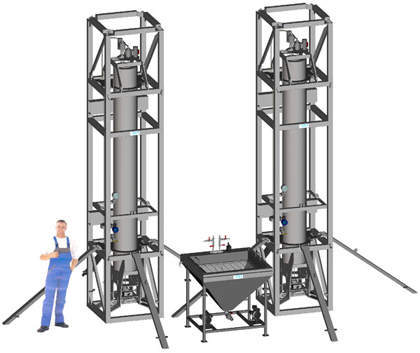

Ongoing testing enables us to be best prepared for the perpetually changing requirements of our customers in the onshore and offshore business. Therefore ANT has developed WAS cutting units for different pressure stages (700bar , 1,200bar, 1,500bar, 2,000bar), but also the largest and most powerful WAS equipment in the world operating at 2,500bar. The AMU Twin-2500-100 offers two abrasive mixing units with each 100L (200kg abrasive). Our WAS cutting units can be operated for an impressive 70 minutes without the need to stop for refilling the mixing unit. This results in a significant saving in time and money. By using a 1.0mm nozzle you achieve a cutting performance of 10mm/min in 300mm steel.

All units are available by purchase or rental and we also provide experienced, licensed offshore trained personnel for worldwide service jobs if requested.

CUTTING TABLES AND MANIPULATION SYSTEMS

ANT manufactures specialised manipulators and cutting tables that ensure safe guidance of the nozzle when cutting with high-pressure water jets. With the aid of these cutting devices, it is possible to control the cutting process from a large distance so that peoples’ lives are not endangered in explosion-risk or other sensitive areas. Our manipulators and cutting tables are designed and built to satisfy most requirements:

- Precise nozzle guidance for accurate cuts

- Flexible and mobile construction, suitable for building sites and underwater applications

- Resistance in use of abrasive

- Adjustable cutting velocity

- Absorption of reactive forces during the cutting process

- Adjustable nozzle distance

The company’s special purpose machinery department designs and builds high-quality manipulators for a broad range of applications above and under water, according to the customers’ requirements.

Our highly flexible manipulation systems are ideal for cutting out complex structures such as windows, manholes, cut-outs and circular sections as well as for rotationally symmetrical geometries, especially pipes.