Kraken Robotic Systems, a subsidiary of Canadian marine technology company Kraken Robotics, has secured $1.8m funding to develop a mooring chain laser inspection sensor that can be used in offshore oil and gas applications.

The company secured the funding for Kraken’s SeaVision 3D underwater laser imaging system after completing trials of the sensor with Canadian company Husky Energy.

Husky will provide $1.26m in cash and in-kind services, and the Government of Newfoundland and Labrador will provide $540,000 through the Innovation and Business Investment Corporation. The cash component of the project will be $720,000.

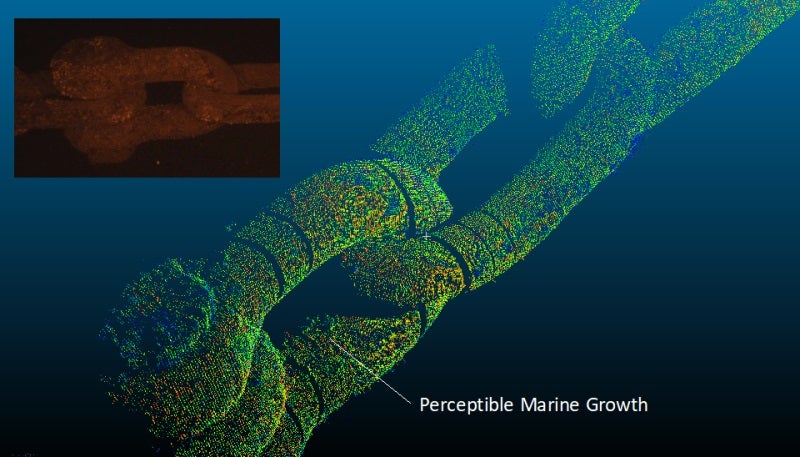

Kraken and Husky jointly tested the system to inspect mooring chains at the SeaRose Floating Production, Storage and Offloading (FPSO) vessel in October 2018. The results showed that the SeaVision technology can inspect a mooring chain and provide the specifications needed by the regulators.

Under the 16-month project, Kraken and Husky will work to address identified technology gaps. The objective is to commercialise SeaVision as a contactless inspection tool for the offshore oil and gas industry.

Kraken president and CEO Karl Kenny said: “Kraken is developing a SeaVision 3D laser scanning service that has the potential to reduce overall operational risk and costs.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“The service will provide an efficient contactless measurement process that produces the required class measurement and the 3D digitalization of the FPSO mooring chains.

“SeaVision can address the local and global mooring chain inspection market needs for both the oil and gas and offshore floating wind power industries.

“Upon project conclusion we expect to have an effective, underwater 3D laser scanning service, qualified with international classification society standards (i.e., DNV), that adds significant value for subsea asset integrity inspections.”

The laser scanning sensor solution will carry out contactless mooring chain inspection from a two-metre stand-off distance. SeaVision will be able to measure a single link in a few seconds, and also reduces environmental concerns as it is a piece of electro-optical equipment.

The scanner sensor technology is expected to reduce the duration of a mooring chain inspection from approximately 10 days to two days. The technology can also be used for floating wind farms, as each floating wind farm is expected to have more than 50 mooring legs per farm.