TD Williamson (TDW) has prevented a major gas supply interruption for residents and businesses in Jakarta, where it carried out a complex subsea pipeline pressure intervention offshore Indonesia.

The company is said to have carried out the hot tap and stopple plugging operation for contractor Timas Suplindo in cooperation with Offshore Construction Specialists on behalf of Pertamina.

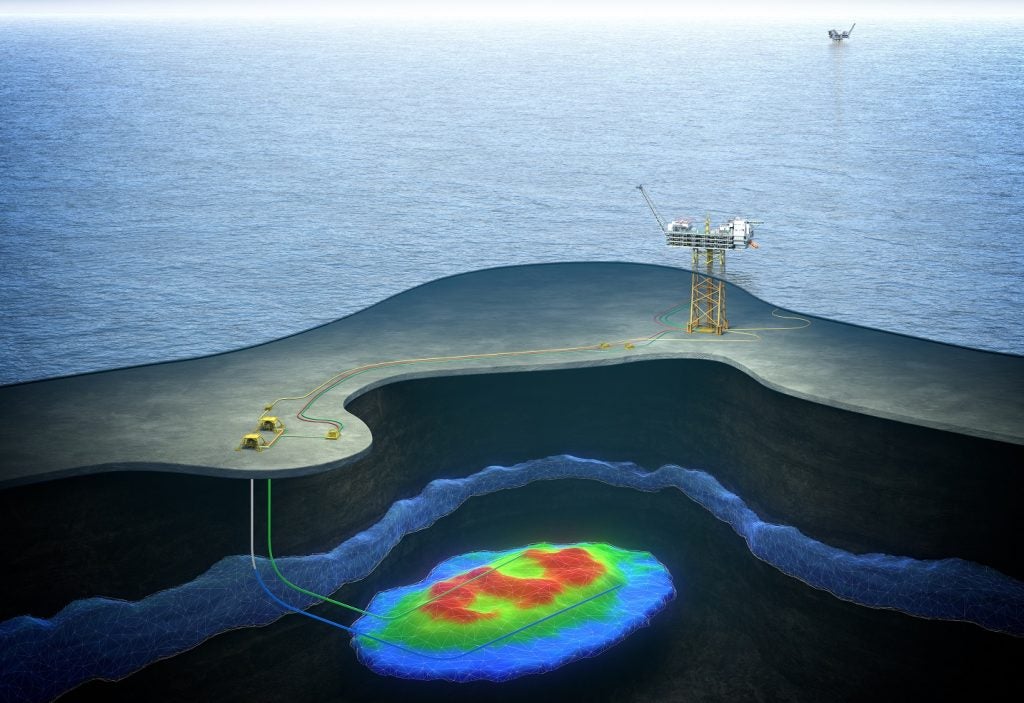

The task was performed on sections of the pipeline network attached to the Lima Flow Station in the North WestJavaSea and work was carried out as part of the Lima Subsidence Remediation project.

According to the company, work was performed in a bid to raise the Lima Flow Station, which consists of compression, service and process platforms, as well as a platform bridge, flare bridge and tower.

Pertamina execution lead Edward Sinaga said half of the nine million who live in Jakarta rely upon natural gas supplied from Lima field, so the stakes were considerably high.

See Also:

"Without gas from Lima field, much of the city would have been thrown into chaos, without power and in some cases, electricity, which was utterly unacceptable," Sinaga said. "It was critical that supply to the city remain steady while jacking operations took place."

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataSeveral lines were needed to be installed to bypass the 14in and 20in MGL pipelines, to ensure that production and supply would continue without any hurdles during remediation works.

The pipelines extend from the TLA and TLD platforms to L-PRO.

TDW was engaged by Pertamina to isolate the affected lines so that temporary bypass lines could be installed, which gas would flow through to ensure an uninterrupted supply to Jakarta.

The company developed a solution that required a series of subsea activities to maintain flow and facilitate the installation of the bypass lines.

The activities include nine hot taps followed by simultaneously executing stopple plugging operations in six different locations.

TDW mobilised equipment from North America, Europe and Asia Pacific to the hot tap and stopple plugging operation site.

Following installation and commissioning of the temporary bypass lines, the five-member team could begin with setting the stopple plugs in six different locations.

The team worked from the dive support vessels at depths up to 131ft, used a full complement of specialist machines to hot tap the pipelines, and stopple plugging systems with Lock-O-Ring Plus fittings to plug them for final completion.

Cold-cutting of the isolated pipeline for the installation of subsea in-line ball valve commenced after the line has been safely isolated and within a short span of time all of the lines were hot tapped, stopple plugs set and successfully isolated.

Image: Pertamina EP Indonesia lowering stopple system. Photo: courtesy of TD Williamson, Inc.

.gif)