Transvac Ejectors can be used for a variety of Produced Water Treatment duties such as:

- Pressure boosting after hydrocyclones

- Pumping slurry as part of a solids handling / separation system

- Flow boosting for separator flushing applications

- Desanding for gas flotation unit

- Desanding for produced water desanders

- Sand cleaning / scrubbing

- Flushing slurry lines following sand removal

Transvac Sand Slurry Ejector are designed and manufactured in accordance with the client’s piping standards (materials include Super Duplex, Duplex & Carbon steel). As standard, a robust special grade of ceramic is used for the Ejector internals to resist abrasion.

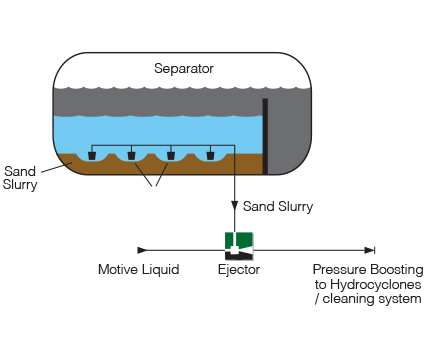

Sand Slurry Pumping from Separators

Transvac Sand Slurry Ejectors are an ideal method of transporting sand slurries from Separators or Cyclones as part of a de-sanding / sand washing system.

Accumulated sand is normally fluidised to ensure it will flow, prior to entering the suction port of the Ejector. The motive fluid can be Produced Water or pressurised water sources.

Sand Cleaning and Recycling

Transvac Sand Slurry Ejectors provide a high-shear environment suitable for removing oil from sand, whilst effectively pumping and recirculating the slurry around the system. Transvac has successfully taken this technology subsea.

Oil / Gas Flotation with Micro-Bubble Technology

Transvac has many years experience in small bubble generation. Our Ejectors are effective at creating small bubbles as part of an oil / water separation process (flotation). In many cases an Ejector is also used as a simple gas recovery / venting device. This eliminates the need for further mechanical pumps.