When design fulfills all project requirements, it contributes to "no defect" plant engineering. Information is unfortunately often improperly captured across plant lifecycle stages. It leads to lack of traceability, loss of data integrity, and difficulty in knowledge utilization.

Safe Plant Engineering is able to help managing multi-discipline engineering information in an integrated way, from definition of requirement to physical design passing through functional and logical process definition. Cross-linking of such different engineering elements delivers better impact analysis in case of changes and increases overall quality.

Attributes / key data:

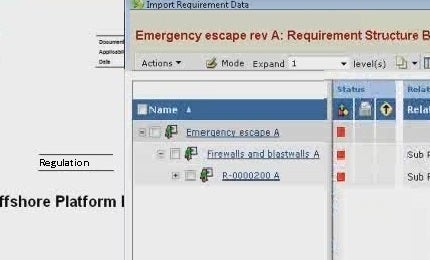

- Decompose into unique requirements your contract and regulations

- Work breakdown structure mapped with requirements

- Engineering definition and requirementremain consistent

- Overall quality and traceability is improved

- Certification and regulatorycompliance is facilitated